Accelerated Aging Chamber

Irradiance Range:35~150 W/㎡

Bandwidth Measurement:300nm~400nm (340nm or 420nm)

Black Panel Temperature:BPT 35 ~ 85 ℃ ±2℃

Humidity Range:50% ~ 98% RH

Humidity Deviation:± 5% RH

Water Spray Cycle:1~9999H59M (Adjustable)

- Product Description

Accelerated Aging Chamber Manufacturer & Supplier

LIB industry is a leading manufacturer and supplier of accelerated aging chamber, It is designed to accurately simulate and assess the effects of various environmental factors on materials and products. With a strong emphasis on quality, reliability, and customization, we aim to be the preferred partner for businesses seeking advanced testing solutions.

It complies with international standards such as ASTM D2436, ASTM D4332, and ASTM F1980, which define the requirements for testing the accelerated aging of materials.

Technical Specifications

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

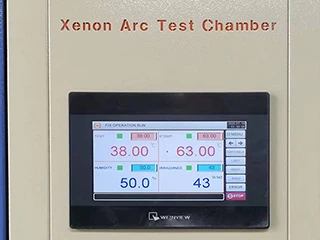

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Humidification System | External isolation, stainless steel surface evaporation humidifier |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Product Details

|

|

|

| Controller PID programmable color touch screen controller Network connection computer. | Workroom The internal material is 304 stainless steel, rust-proof to high and low temperature Rotating specimen holder | Castors Install 4 castors for ease moving, and with brakes function. Caster height adjustable. |

|

|

Accelerated Aging Chamber Features

Our xenon test chambers offer precise control of temperature and humidity for accurate simulation of aging conditions, uniform air circulation for consistent testing results, user-friendly interface for easy operation and monitoring, compliance with international standards for reliable testing, and comprehensive testing capabilities for evaluating material durability.

1. Advanced Light Source Technology for Precise Testing

Understanding your particular testing prerequisites is significant. Our chambers include two particular light source alternatives to coordinate your testing needs perfectly.

UV-Based Systemsexcel at assessing chemical debasement, chalking, and yellowing impacts. These frameworks center on the most harming UV wavelengths that cause polymer breakdown and surface deterioration.

Xenon-Based Systemsprovide full-spectrum sun powered recreation for comprehensive color speed testing. They reproduce characteristic daylight more precisely, making them perfect for assessing visual changes and color stability.

Both frameworks highlight long-lasting light innovation with amplified benefit life up to 1600 hours. Our built-in irradiance control framework naturally keeps up steady light escalated all through testing cycles, guaranteeing dependable information each time.

2. Comprehensive Environmental Simulation Capabilities

Real-world maturing includes more than fair light presentation. Our chambers make synergistic impacts that reflect real open air conditions.

Condensation and Spray Cycles accurately reenact morning dew and precipitation conditions. The condensation stage is especially compelling for plastic and coating corruption testing, regularly uncovering shortcomings that light alone cannot expose.

Precise Temperature Control through progressed dark board temperature (BPT) and dark standard temperature (BST) observing guarantees your tests involvement practical surface warming conditions. This exactness temperature administration sets proficient gear separated from essential testing chambers.

3. Standard Compliance Made Simple

Meeting international testing standards has never been easier. Our user-friendly control system includes pre-programmed testing protocols for major standards including ISO 4892, ASTM G154/G155, and SAE J2527.

The one-touch standard mode determination disposes of programming mistakes and guarantees reliable comes about over distinctive administrators. Built-in information logging captures each parameter all through your test cycle, making comprehensive reports that fulfill review requirements.

Why Choose Xi'an LIB Environmental Simulation Industry

1. Professional Quality Assurance: We follow strict ISO 9001 Quality Management System protocols. All items carry CE certification and experience third-party testing by SGS and TUV, ensuring universal compliance and dependable performance.

2. Comprehensive After-Sales Support: Every Accelerated Aging Chamber includes a 3-year guarantee with lifetime benefit back. Our 24/7 worldwide back arrange guarantees you're never alone when questions emerge. If repairs aren't conceivable amid guarantee, we give brand-new substitution equipment.

3. Custom Engineering Solutions: Our experienced R&D group specializes in non-standard plans and custom applications. We work closely with you to create custom-made arrangements that meet your particular testing necessities and convey ideal comes about for your industry.