mini thermal chamber

Lowest Temperature:-20℃/-40℃/-60℃/-86℃;

Temperature Range:-70℃~+150 ℃;

Humidity Range:10% ~ 98% RH;

Cooling Type:Air cooled

Refrigerant:Environmental refrigerant

Stand as option

Temperature and Humidity System

- Product Description

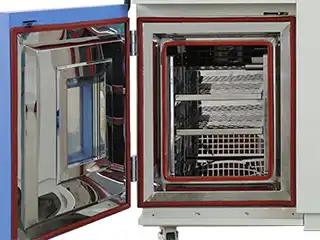

LIB Industry's mini thermal chamber

A mini thermal chamber is a device used in various industries and research settings to test the effects of temperature on products, materials, components, or devices. It's essentially a controlled environment chamber designed to subject objects to different temperature conditions.

These thermal chamber typically have the capability to both heat and cool, allowing for precise control over a wide range of temperatures. They can simulate extreme temperature conditions that the object might encounter during its normal operation or in various environments.

Technical Specifications:

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W | |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | |

Temperature Fluctuation | ± 0.5 ℃ | |

Temperature Deviation | ± 2.0 ℃ | |

Humidity Range | 20% ~ 98% RH | |

Humidity Deviation | ± 2.5% RH | |

Cooling Rate | 1 ℃ / min | |

Heating Rate | 3 ℃ / min | |

Cooling system | Mechanical compression refrigeration system | |

Controller | Programmable color LCD touch screen controller Ethernet connection | |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection | |

Exterior Material | Steel Plate with protective coating | |

Interior Material | SUS304 stainless steel | |

Thermal Insulation | Polyurethane foam and insulation cotton | |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves | |

Product Details:

|

|

|

| Workroom The internal material is 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion | Cable hole A standard test hole with plugs The standard inner hole diameter is 50mm/100mm/200mm | Connect to a computer PID programmable color touch screen controller Network connection computer Remote control |

|

|

Product Advantages:

◇Space Efficiency: They're compact and designed to fit on a workbench, making them ideal for smaller laboratories or testing facilities.

◇Cost-Effective: Compared to larger chambers, they are usually more affordable to purchase, operate, and maintain.

◇Wide Range of Applications: Suitable for various applications, such as testing electronic components, materials, pharmaceuticals, and more.

◇Rapid Testing: Mini thermal chamber enables fast and controlled thermal cycling for accelerated testing of products' thermal resistance and reliability.

Mini Thermal Chamber Applications:

Electronics Testing: Assessing components' behavior under different temperature conditions, such as semiconductors or circuit boards.

Material Testing: Evaluating the thermal properties of various materials for industries like construction, aerospace, and automotive.

Product Development: Assessing the performance and durability of products under extreme temperature conditions before market release.

Quality Control: Verifying the reliability and performance of manufactured goods in controlled thermal environments.

FAQ:

What temperature ranges can mini thermal chamber achieve?

The low temperature is -20℃/-40℃/-60℃/-86℃, humidity is 20% to 98%RH.

What the cooling rate of this thermal chamber?

Standatd temperature change rate is 1℃/min, can reach to 5℃/min or 10℃/min.

Are small thermal chamber user-friendly?

Yes, user-friendly interfaces for programming and monitoring temperature profiles.

Can these chambers simulate extreme temperature conditions?

Yes, they are designed to create extreme temperature conditions to test the resilience and performance of products or materials.

.webp)