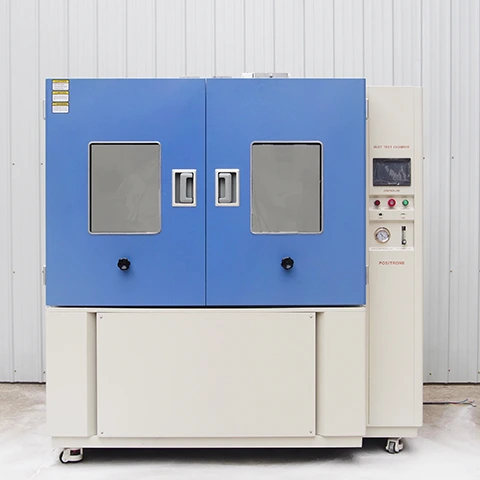

DI-2000 IP6X Dust Chamber

Model:DI-1000

Capacity:800L/1000L/1500L/2000L and more

Temperature Range:Ambient ~ +50℃

Humidity Range:< 30% RH

Normal Wire Diameter: 50um

Nominal Width of a Gap Between wires:75um

- Product Description

DI-2000 IP6X Dust Chamber Manufacturer & Supplier

The LIB Industry DI-2000 IP6X Dust Chamber is designed to perform dust intrusion and particle ingress testing on electrical enclosures and components according to IEC 60529 and related IP standards. With programmable dust circulation cycles and heating air temeprature, this chamber provides reliable IP testing capabilities. The IP dust test chamber has a stainless steel interior and clear observation windows. It uses an electric dust circulating fan to aintain uniform dust distribution inside test room. The programmable PLC allows custom test profile creation.

Specifications

Model | DI-2000 |

Internal Dimension (mm) | 1000*2000*1000 |

Overall Dimension (mm) | 1330*2450*1990 |

Useful Volume (L) | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Vacuum System | Equipped with a pressure gauge, air filter, pressure regulator, connecting tube |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Door Lock | Electromagnetic lock |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection;Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Product Details

|

|

|

Internal Power Supply The workroom is equipped with a single-phase 16A internal power interface. Supply electricity to test specimen inside of the workroom | Build-in lighting The built-in dustproof LED lighting inside the workroom Makes it clear to observe the test specimen. | Workroom The internal material is 304 stainless steel, mirror surface, rust-proof Standard configuration: sample rack |

|  |

Key Features

1. Smart Vacuum System Design

You'll appreciate our multi-port vacuum association framework that permits concurrent testing of 2-3 expansive components. The advanced weight checking consequently keeps up the exact differential weight required for IP6X compliance. No more manual alterations or mystery – the framework handles weight direction for you.

2. Large Capacity Loading Solutions

Getting overwhelming tests into a 2000L chamber shouldn't be a battle. Our low-threshold entryway plan and discretionary test cart framework make stacking direct. The fortified foot stage bolsters up to 500kg, whereas movable stainless steel racking lets you test different littler tests simultaneously.

3. Automated Dust Management

TheDI-2000 IP6X Dust Chamber highlights effective warming coats that consequently dry your talcum powder some time recently testing starts. This avoids clumping in the circulation framework – a basic highlight for expansive chambers. Our one-touch powder recuperation framework with vibration help implies changing handfuls of kilograms of tidy takes fair minutes, not hours.

Why choose LIB Industry's IP69K dust chamber?

(1)LIB Industry's DI-2000 IP6X Dust Chamber provides a reliable testing instrument that meets key requirements of IEC 60529 and related standards for evaluating ingress protection levels. With over 14 different models ranging from 800L to 2000L capacity, LIB Industry offers chambers suited for small to large enclosures and housings.

(2)The temperature range of ambient to +80°C allows testing across both room and elevated temperatures. The powerful circulation fan generates wind with uniform distribution to simulate real-world dust conditions.

(3)The dust injection quantity can be programmed from 0-10 kg allowing incremental exposure as needed per test specifications. LIB Industry also provides custom dust particle sizes such as 50 microns and gap widths of 75 microns between dust injection tubes to meet standard stipulations.

(4)By providing a broad range of test space volumes, programmable dust parameters, and the ability to conform to IEC 60529 procedures, LIB Industry's product is an excellent choice for laboratories and manufacturers needing to qualify ingress protection ratings for their electrical and electronic products.

Quality You Can Trust

Since 2009, we've built environmental test chambers for industry leaders including Apple, IBM, Amazon, and Mercedes-Benz. Our global network of 29 agents and service centers in Malaysia, Canada, the UK, and the US ensures you receive professional support wherever you are.

.webp)