Mini Climatic Chambers for Battery Performance Testing

Mini Climatic Chambers for Battery Performance Testing

Battery performance testing demands precision environmental control to ensure safety, reliability, and longevity. Mini climatic chambers provide manufacturers and researchers with compact yet powerful solutions for evaluating battery behavior under extreme temperature and humidity conditions. These specialized testing environments simulate real-world scenarios - from arctic cold to tropical heat - allowing engineers to identify potential failures before products reach consumers. As battery technology advances, particularly with lithium-ion and emerging solid-state designs, accurate environmental testing becomes increasingly critical for compliance, quality assurance, and innovation in energy storage solutions.

Importance of Environmental Testing in Battery Research

Predicting Real-World Battery Behavior

Environmental testing reveals how batteries respond to temperature extremes encountered during shipping, storage, and operation. Automotive batteries face scorching summers and freezing winters, while consumer electronics travel through varying climate zones. A mini climatic chamber replicates these conditions in controlled laboratory settings, enabling researchers to predict performance degradation patterns and establish realistic operational parameters.

Identifying Thermal Runaway Risks

Thermal runaway represents one of the most dangerous failure modes in lithium-ion batteries. When internal temperatures rise uncontrollably, chemical reactions accelerate, potentially causing fires or explosions. Environmental chambers equipped with safety features allow controlled observation of battery behavior at elevated temperatures, helping engineers establish safe operating boundaries and design effective thermal management systems.

Accelerating Development Cycles

Traditional testing methods require months of real-time observation. Environmental chambers compress this timeline by subjecting batteries to accelerated aging protocols. By cycling through temperature extremes and humidity variations rapidly, researchers gather years' worth of performance data within weeks, significantly reducing time-to-market for new battery technologies.

How Mini Climatic Chambers Simulate Charging and Discharging Conditions?

Integrated Electrical Testing Capabilities

Modern mini climatic chambers accommodate battery cyclers and testing equipment through specialized cable ports. The TH-80 model features standard 50mm cable holes with silicone plugs, maintaining environmental integrity while allowing real-time electrical connections. This integration enables simultaneous thermal and electrical stress testing, revealing how temperature affects charging efficiency, discharge rates, and internal resistance.

Programmable Temperature Profiles

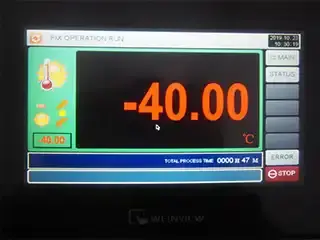

Advanced controllers create complex thermal profiles mimicking actual usage patterns. A smartphone battery experiences rapid heating during fast charging, gradual cooling during standby, and temperature fluctuations during intensive applications. Programmable LCD touchscreen controllers replicate these scenarios precisely, executing multi-step protocols that alternate between heating at 3°C/min and cooling at 1°C/min.

Advanced controllers create complex thermal profiles mimicking actual usage patterns. A smartphone battery experiences rapid heating during fast charging, gradual cooling during standby, and temperature fluctuations during intensive applications. Programmable LCD touchscreen controllers replicate these scenarios precisely, executing multi-step protocols that alternate between heating at 3°C/min and cooling at 1°C/min.

Humidity Control for Realistic Conditions

Battery performance varies significantly with humidity levels. Moisture can penetrate protective casings, affecting electrochemical reactions and accelerating corrosion. The humidity range of 20% to 98% RH allows testing across arid desert conditions to humid tropical environments, ensuring batteries maintain performance regardless of deployment location.

Temperature and Humidity Effects on Battery Life and Safety

Capacity Degradation at Temperature Extremes

Battery capacity diminishes substantially outside optimal temperature ranges. Cold environments below -20°C slow chemical reactions, reducing available power and increasing internal resistance. Conversely, temperatures exceeding 60°C accelerate electrolyte decomposition and solid electrolyte interface growth, permanently reducing storage capacity. Environmental chambers quantify these effects through controlled exposure studies.

Temperature Range | Capacity Impact | Common Issues |

-70°C to -20°C | 30-50% reduction | Increased resistance, slow charging |

20°C to 40°C | Optimal performance | Minimal degradation |

60°C to 150°C | Accelerated aging | Electrolyte breakdown, thermal stress |

Moisture-Induced Failure Mechanisms

Humidity penetration causes multiple failure pathways in battery systems. Water molecules react with lithium salts in electrolytes, producing hydrofluoric acid that corrodes internal components. Metal current collectors oxidize when exposed to moisture, increasing resistance and generating heat. The water purification and recirculation system in mini climatic chambers maintains precise humidity levels, enabling reproducible testing of moisture resistance.

Thermal Cycling Stress Analysis

Repeated expansion and contraction from temperature cycling creates mechanical stress in battery components. Electrode materials expand at different rates than separators and casings, potentially causing delamination or micro-cracks. By cycling between extreme temperatures, environmental chambers reveal structural weaknesses before they manifest in field failures, allowing engineers to optimize material selection and assembly methods.

Testing Protocols for Lithium-Ion and Solid-State Batteries

Safety-Focused Lithium-Ion Evaluation

Lithium-ion batteries require specialized safety precautions during testing. Mini climatic chambers incorporate multiple protection features: over-temperature shutdown, refrigerant high-pressure protection, and observation windows with interior lighting. These safety options allow visual monitoring during potentially hazardous tests while maintaining researcher protection. Testing protocols typically include thermal abuse, overcharge scenarios, and short-circuit simulations at controlled temperatures.

Emerging Solid-State Battery Challenges

Solid-state batteries promise improved safety and energy density but introduce unique testing requirements. Solid electrolytes exhibit different temperature dependencies than liquid electrolytes, requiring precise thermal control to evaluate ionic conductivity across operating ranges. The temperature fluctuation of ±0.5°C ensures accurate characterization of these temperature-sensitive materials, critical for optimizing solid-state battery formulations.

Standardized Cycling Protocols

Industry-standard testing protocols define specific temperature profiles and cycle counts. UN 38.3 transportation testing requires thermal cycling between -40°C and +75°C, while automotive standards demand operation verification from -30°C to +60°C. The programmable controller stores multiple protocols, ensuring consistent testing across different battery chemistries and applications.

Battery Type | Temperature Range | Typical Cycle Count | Duration |

Consumer Li-ion | -20°C to +60°C | 500-1000 cycles | 2-4 weeks |

Automotive EV | -40°C to +85°C | 1000-3000 cycles | 6-12 weeks |

Solid-State | -30°C to +100°C | Variable | 4-8 weeks |

Data Accuracy and Monitoring Systems in Battery Testing

Real-Time Temperature Distribution Mapping

Temperature uniformity throughout the chamber interior directly affects result reliability. The TH-80 model maintains temperature deviation within ±2.0°C across the 80-liter workspace, ensuring consistent conditions for multiple battery samples. Strategic placement of SUS304 stainless steel shelves promotes air circulation, minimizing thermal gradients that could introduce testing variability.

Ethernet Connectivity and Data Integration

Modern research demands seamless data integration with laboratory information systems. Ethernet connectivity enables remote monitoring and automatic data logging to centralized databases. USB ports facilitate immediate data download for analysis, while PC integration allows researchers to monitor multiple chambers simultaneously, optimizing laboratory workflow and reducing manual documentation errors.

Continuous Environmental Verification

Accuracy depends on continuous sensor calibration and verification. Temperature fluctuation of ±0.5°C and humidity deviation of ±2.5% RH require regular maintenance and calibration protocols. Built-in self-diagnostic systems monitor refrigeration performance, water levels, and electrical systems, alerting operators to potential issues before they compromise testing integrity.

Compliance with Industry Standards for Battery Reliability

International Safety Certifications

Battery testing equipment must meet stringent international standards. CE certification confirms compliance with European safety directives, covering electromagnetic compatibility, electrical safety, and environmental protection. These certifications provide confidence that testing results will be recognized by regulatory bodies worldwide, facilitating international product approvals.

UN Transportation Testing Requirements

Shipping batteries requires compliance with UN 38.3 testing standards. These protocols mandate thermal cycling, altitude simulation, vibration, shock, and external short circuit tests. Mini climatic chambers handle the thermal cycling component, maintaining precise control through temperature ranges from -40°C to +75°C over multiple cycles, generating documentation accepted by transportation authorities globally.

Automotive Industry Standards

Electric vehicle batteries face particularly rigorous testing requirements. Standards like ISO 12405, SAE J2464, and IEC 62660 specify environmental testing parameters including temperature shock, thermal cycling, and high-temperature storage. The mechanical compression refrigeration system enables rapid temperature changes necessary for thermal shock testing, meeting automotive industry timelines.

Standard | Application | Temperature Requirements |

UN 38.3 | Transportation safety | -40°C to +75°C cycling |

IEC 62133 | Consumer batteries | -20°C to +75°C storage |

ISO 12405 | Automotive EV | -40°C to +85°C operation |

LIB Industry Mini Climatic Chamber: Precision Battery Testing

Compact Footprint with Maximum Capability

The TH-80 mini climatic chamber delivers laboratory-grade performance within a 900×1210×1000mm overall footprint. This space-efficient design accommodates facilities with limited floor space while providing 80 liters of testing volume. The stainless steel stand with casters enables flexible positioning and easy relocation, allowing laboratories to reconfigure testing areas as research priorities evolve.

Comprehensive Safety Architecture

Battery testing involves inherent risks, making safety systems paramount. Multiple protection layers include over-current protection preventing electrical faults, refrigerant high-pressure protection avoiding system damage, and water shortage protection preserving humidification components. Earth leakage protection safeguards personnel, while humidifier dry-combustion protection prevents fire hazards, creating a secure testing environment for potentially volatile battery chemistries.

Advanced Temperature Control Technology

Achieving the temperature range from -70°C to +150°C requires sophisticated refrigeration engineering. The mechanical compression refrigeration system utilizes polyurethane foam and insulation cotton thermal barriers, minimizing energy consumption while maintaining stability. The 1000W heat load capacity accommodates active battery testing where charging and discharging generate substantial internal heat, ensuring environmental conditions remain stable despite thermal perturbations from test samples.

Customization and Integration Options

Research requirements vary significantly across applications and industries. LIB Industry provides customization options including adjustable shelf heights, cable hole diameters from 50mm to 200mm, and integration with local laboratory software systems. OEM options enable complete system integration, allowing the mini climatic chamber to function seamlessly within existing testing infrastructures and automated quality control systems.

Conclusion

Mini climatic chambers represent essential infrastructure for advancing battery technology safely and efficiently. These compact testing environments enable comprehensive evaluation of battery performance across extreme conditions, accelerating development while ensuring compliance with international safety standards. As energy storage demands intensify globally, precision environmental testing becomes increasingly critical for delivering reliable, safe battery products.

FAQs

What temperature range is necessary for comprehensive lithium-ion battery testing?

A comprehensive testing program should cover -40°C to +85°C for automotive applications and -20°C to +60°C for consumer electronics. This range captures extreme storage and operational conditions, revealing potential failure modes and establishing safe operating boundaries for various climates.

How does chamber size affect battery testing accuracy?

Chamber interior volume should provide adequate space around test samples for uniform air circulation. The 80-liter capacity allows proper spacing between batteries, minimizing thermal interaction between samples while maintaining ±2.0°C temperature deviation, ensuring each battery experiences identical environmental conditions.

Can mini climatic chambers accommodate automated battery cycling equipment?

Modern mini chambers include cable ports with silicone seals that maintain environmental integrity while connecting external battery cyclers. The programmable controller synchronizes with cycling equipment through Ethernet connectivity, enabling coordinated thermal and electrical testing protocols without compromising chamber conditions.

LIB Industry delivers turn-key environmental testing solutions as a leading mini climatic chambers manufacturer and supplier. Our expert team provides research, design, production, installation, and training services customized to your battery testing requirements.

Contact us at ellen@lib-industry.com to discuss your specific testing needs.