Temperature Cycling Chamber

Model:TR5-500

Lowest Temperature:-20℃/-40℃/-60℃/-70℃;

Cooling Rate:10 ℃ / min (average)

Heating Rate:10 ℃ / min (average)

The temperature ramp rate is controllable at 5℃ / 10℃ / 15℃ per minute.

Volume:100L, 225L, 500L, 800, 1000L, 2000L, 3000L

- Product Description

Temperature Cycling Chamber Manufacturer & Supplier

LIB Industry temperature cycling chamber is used to simulate extreme temperature conditions for testing the performance and reliability of various products. It is commonly used in industries such as aerospace, automotive, electronics, and pharmaceutical. The chamber equipped with a temperature control system that can rapidly and accurately change the temperature within a specified range. The temperature change rate can reach to 5 ℃ / min (10 ℃ / min).

Technical Specifications

Model | TR5-100 | TR5-225 | TR5-500 | TR5-800 | TR5-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W | ||||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 5 ℃ / min | ||||

Heating Rate | 5 ℃ / min | ||||

Cooling system | Mechanical compression refrigeration system | ||||

Refrigerating unit | French TECUMSEH compressor | ||||

Heating Element | Nichrome heater | ||||

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link | ||||

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||||

Air Circulation | Centrifugal wind fan | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection | ||||

Exterior Material | Steel Plate with protective coating | ||||

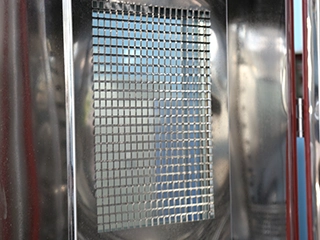

Interior Material | SUS304 stainless steel | ||||

Thermal Insulation | Polyurethane foam and insulation cotton | ||||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | ||||

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves | ||||

Product Details

|

|

|

| Explosion-proof system Explosion-proof door and viewing window Equip with smoke detector and buzzer Water spray against fire | Cable hole A standard test hole with plugs 50mm/100mm/200mm Soft silicone plug seal; Metal enclosure closed | PC Link Ethernet connect to PC for easy operation Match to the local laboratory software USB to download data |

|

|

Why Choose LIB Thermal Cycling Test Equipment?

1. Transparent Core Technology Parameters

We accept in total straightforwardness when it comes to specialized details. Our warming and cooling rates arelinear, not normal values that can delude your testing necessities. You'll get nitty gritty stacking capacity charts appearing execution beneath distinctive test weights, guaranteeing reliable comes about whether testing with light electronic components or overwhelming car parts.

2. Advanced Refrigeration System Design

Our multi-stage vitality control framework highlights PID control with programmed refrigerant stream alteration through electronic extension valves. The premium Bitzer cascade refrigeration framework guarantees solid operation amid seriously cycling tests. Progressed anti-frost innovation keeps up proficiency amid amplified test cycles.

3. Sample Safety Protection

Your important test tests merit greatest assurance. Autonomous equipment temperature limiters work nearby computer program controls for dual-layer security. Discretionary smoke discovery and fire concealment framework interfacing are accessible for battery testing applications. Weight discharge valves naturally adjust inside weight amid fast temperature transitions.

4. Smart Operation and Data Traceability

Generate testing curves with one-click programming for up to 100 preset cycles. Remote monitoring capabilities let you track test progress from anywhere via mobile app or web interface. All data storage meets FDA 21 CFR Part 11 compliance standards for complete audit traceability.

5. Precision Temperature and Humidity Control

High-precision PT100 Class A sensors provide 0.001°C resolution for exceptional accuracy. Our PID controller maintains temperature within ±0.5°C and humidity within ±2.5%RH, ensuring uniform sample exposure and repeatable test results.

6. Industrial Durability and Safety

The SUS304 stainless steel insides stands up to erosion indeed in high-humidity conditions. The 4mm A3 steel outline with powder coating gives industrial-grade strength. Comprehensive security frameworks incorporate electrical spillage security, establishing security, stage arrangement observing, and programmed over-temperature shutdown.

Professional Quality Assurance

Since 2009, we've maintained strict ISO 9001 Quality Management System standards. All hardware gets CE certification and third-party testing by SGS and TUV specialists. This guarantees universal compliance, steady execution, and tall unwavering quality for your basic testing applications. Our worldwide associations with industry pioneers like Apple, IBM, Amazon, and Mercedes-Benz illustrate the believe put in our testing arrangements. With 29 universal specialists and benefit centers in Malaysia, Canada, the UK, and the US, we give comprehensive back worldwide.

Complete Service Support

Every Temperature Cycling Chamber includes a 3-year warranty with lifetime service support. Our 24/7 global support team ensures minimal downtime for your testing operations. If repair isn't possible within the warranty period, we'll provide a brand-new replacement unit. Our customization capabilities extend beyond standard specifications. Whether you need modified chamber dimensions, specialized sample fixtures, or integration with existing laboratory systems, our engineering team develops tailored solutions for your unique requirements.

.webq.jpg)