Thermal Shock Test Chamber

Lower limit Temperature:-75℃

Upper limit Temperature:+220℃

Temperature Range:-70℃~+220 ℃

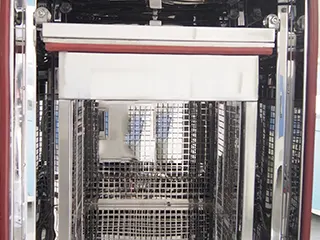

The specimen is automatically transferred from the cold chamber to the hot chamber by basket.

Temperature Recovery Time: Within 5 minutes

Refrigerant: Environmental refrigerant

- Product Description

Thermal Shock Test Chamber Manufacturer & Supplier

LIB industry's Thermal Shock Test Chamber can perfrom thermal shock testing from -70 to +200°C.The specimen automatic transferred from cold chamber to hot chamber by basket. During the test, the sample is rapidly transferred between the hot and cold compartments, creating thermal stress. Thermal shock test chambers are equipped with precise temperature control systems to achieve the desired temperature ranges and transition times.

Technical Specifications

Model | TS-162 | TS-340 | TS-500 | TS-1000 |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | 650*650*500 | 850*850*700 |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | 1910*1220*2265 | 2110*1420*2665 |

Interior Volume (mm) | 22L | 72L | 211L | 505L |

Loading Capacity | 20kg | 30kg | 50kg | 60kg |

Upper limit Temperature | +220℃ | |||

Heating Time | Ambient ~ + 200℃, within 30 minutes | |||

Lower limit Temperature | -75℃ | |||

Cooling time | Ambient ~ -70℃, within 30 minutes | |||

High Temperature Exposure Range | Ambient +20 ~ +200°C | |||

Low temperature Exposure Range | –65 ~ -5°C | |||

Temperature Fluctuation | ≤±0.5℃ | |||

Temperature Deviation | ≤±3 ℃ | |||

Temperature Recovery Time | Within 5 minutes | |||

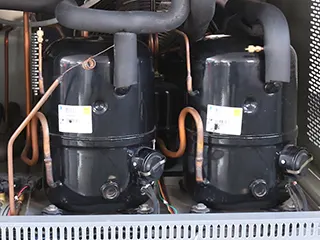

Cooling System | Mechanical compression refrigeration system | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

Safety Device | Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection | |||

Exterior Material | Steel Plate with protective coating | |||

Interior Material | SUS304 stainless steel | |||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | |||

Standard Configuration | 2 shelves | |||

Product Details

|

|

|

| Cooling system Mechanical compression refrigeration system French TECUMSEH compressor Environmentally friendly refrigerant | Cable hole The standard inner hole diameter is 50mm/100mm/200mm Located on the basket | Basket The specimen automatic transferred from cold chamber to hot chamber by basket. The basket slides vertically and smoothly through rail |

|

|

Understanding Your Testing Requirements

1. Choosing the right warm stun chamber engineering depends on your particular testing needs. We offer two particular setups to coordinate your requirements:

2. Two-Basket Plan (Support Sort): Highlights pneumatic bushel development with ultra-fast move speeds. Our progressed pneumatic lifting framework incorporates damping buffer plan to kill mechanical vibration amid test transfer.

3. Three-Zone Plan (Damper Sort): Utilizes stationary tests with damper exchanging innovation. Culminate for expansive, overwhelming tests or dynamic testing scenarios requiring cable associations, as test leads stay undisturbed all through the process.

Advanced Engineering Features

1. Rapid Temperature Recovery System

Our exclusive pre-heat and pre-cool zone plan guarantees adequate warm vitality saves for moment temperature moves. The framework keeps up ideal recuperation times indeed beneath full stack conditions, assembly strict prerequisites of MIL-STD-810 and JEDEC standards.

2. Superior Temperature Control

Precision Thermal Shock Test Chamber operation depends on progressed PID closed-loop control frameworks matched with PT100 A-grade sensors. This combination conveys remarkable precision whereas centrifugal fans guarantee uniform temperature dissemination all through the test space.

3. Robust Development Design

All-stainless steel insides development withstands persistent warm development and compression cycles. Specialized welding strategies avoid seal disappointment and split arrangement, guaranteeing long-term unwavering quality indeed after thousands of test cycles.

4. Intelligent Support Features

Automatic defrost cycles actuate each 100 test cycles, avoiding ice buildup on evaporator coils. This shrewdly framework minimizes downtime and keeps up steady execution all through amplified testing periods.

5. Enhanced Safety Protection

For lithium battery testing applications, our chambers feature optional explosion-proof safety design including:

· Reinforced chamber construction

· Pressure relief systems

· Automatic power disconnect protection

· High-sensitivity smoke detection

· Multiple safety interlock mechanisms

These security highlights successfully ensure administrators and diminish fire or blast dangers, guaranteeing compliance with exacting security standards.

Why Choose Our Solution

1. Professional Quality Assurance: Every unit follows ISO 9001 Quality Management System protocols with CE certification and third-party testing by SGS and TUV specialists. This guarantees worldwide standard compliance, steady execution, and tall reliability.

2. Comprehensive Benefit Bolster: All gear incorporates 3-year guarantee scope furthermore lifetime benefit back. Our 24/7 worldwide bolster organize gives quick help, with modern substitution units accessible if repair isn't conceivable inside guarantee periods.

3. Custom Designing Capabilities: Solid ability in non-standard plan and custom inquire about empowers custom-made arrangements for differing application necessities, conveying ideal comes about over different industries.

.webq.jpg)