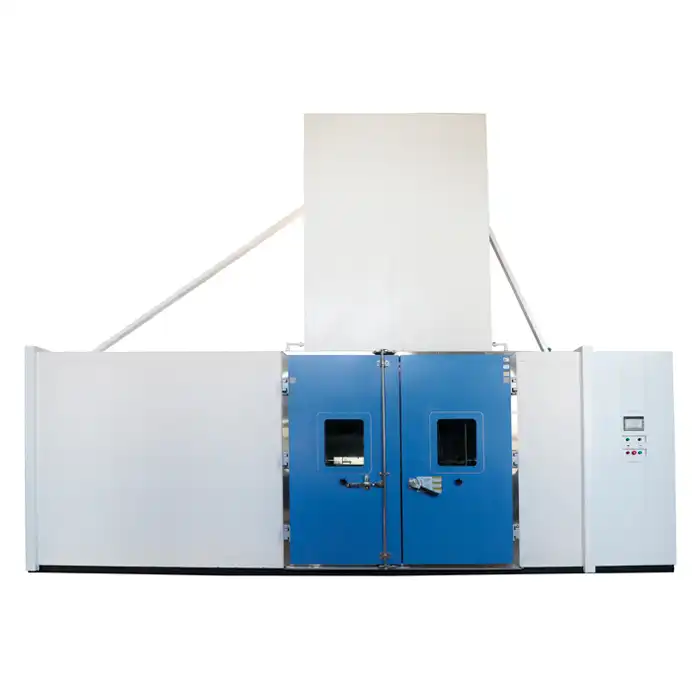

Blowing Rain Test Chamber

Name:blowing rain test chamber

Final rain droplet velocity: 9m/s on test item

Rainfall rate: ≥ 1.7 mm/min

Droplet size: 0.5mm ~ 4.5mm

Test specimen heating range: Water temperature +10°C (max +55°C)

Test time: 0 ~ 999min. adjustable

Nozzle pressure: 276kpa

Rainfall rate: 20.8L/min

Droplet size: 0.5mm ~ 4.5mm

- Product Description

Blowing Rain Test Chamber Manufacturer & Supplier

LIB industry is professional Blowing Rain Test Chamber manufacturers and suppliers in China, to buy or wholesale from our factory. For quotation, contact us now. The LIB Blowing Rain Test Chamber provides realistic rain simulation testing to evaluate product protection against wind-driven rain. Fully automated operation and data logging ensure efficient testing to industry standards. LIB MIL-STD 810 rain test chamber is used for evaluating the resistance of a system to water and rain in accordance with MIL-STD-810h.

Technical Parameters

Model | RIM-1000 |

Internal Dimension | 1000*1000*1000 mm D*W*H |

Overall Dimension | 2600*5400*4100 D*W*H |

Interior Volume | 1000L |

The load Turntable | 50kg |

The diameter of Turntable | 800mm |

Rain and Blowing Rain | |

Final rain droplet velocity | 9m/s on test item |

Rainfall rate | ≥ 1.7 mm/min |

Droplet size | 0.5mm ~ 4.5mm |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Test time | 0 ~ 999min. adjustable |

Exaggerated | |

Nozzle pressure | 276kpa |

Rainfall rate | 20.8L/min |

Nozzle amount | One nozzle for each 0.56m2 of surface area and position each about 48cm from in the test surface |

Droplet size | 0.5mm ~ 4.5mm |

Test time | 0 ~ 999min. adjustable |

Drip | |

Drip area dimensions | 1600*1000mm , height can be adjustable |

Drip holes | 20 to 25.4mm |

Distance between hole | 25mm |

Volume of water | ≥280L/m2/h |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Door Lock | Electromagnetic lock |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810H |

Product Details

|

|

|

| Workroom The internal material is 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion | Build-in lighting The built-in dustproof LED lighting inside the workroom. The light can be turned on and off at the control panel button | Drip Tray The drip tray is made of stainless steel Drip holes are evenly distributed |

|

|

Key Features

1. Powerful Wind Generation System

Our gear highlights high-performance pivotal fans that create wind speeds up to 25m/s. This isn't fair basic water showering – it's genuine driving rain recreation. The variable recurrence wind speed control guarantees reliable, flexible wind current all through your testing cycle. The wind framework works consistently with our splash spouts to make bona fide climate designs. Your tests encounter the same inclining rain affect they would confront in real storm conditions.

2. Advanced Multi-Directional Spray Technology

Our chamber incorporates mobile shower heads that alter vertically and evenly. The 360-degree ring spout cluster guarantees uniform water conveyance over all test surfaces. The pivoting turntable works at 1-7 rpm, giving total introduction scope. Your items get reliable water contact from each point amid testing.

3. Superior Water Management

The coordinates water warming framework controls temperature accurately. This include meets military guidelines requiring particular temperature differentials between water and test surfaces. Our high-efficiency filtration and circulation framework anticipates spout blockages. You'll spare essentially on water costs whereas keeping up reliable splash quality.

4. Comprehensive Standards Compliance

Our hardware completely underpins MIL-STD-810G Strategy 506.6 (Rain) counting Procedure I for Rain and Blowing Rain testing. The chamber moreover meets different universal guidelines for entrance security testing.

The framework precisely duplicates particular precipitation force required by distinctive benchmarks. You can design correct weight settings, splash points, and wind speeds to coordinate your testing protocols.

5. Smart Control and Monitoring

The progressed control framework shows real-time bends for wind speed, water stream, weight, and temperature at the same time. This multi-parameter checking guarantees exact test conditions all through your assessment cycle.Pre-programmed test profiles speed up your workflow. Custom programming choices let you make particular test arrangements for special applications.

Operating Principle

The blowing rain spray chamber operates on the following principles:

1. The test product is secured in the chamber test space.

2. Test parameters are entered on the HMI, including rainfall rate, wind speed, water temperature, and duration.

3. Upon test initiation, rain simulation, wind generation, and heating activate based on the programmed cycle.

4. Sensors monitor test conditions throughout the duration.

5. At completion, the product is checked for water penetration based on MIL-STD- 810H standards.

6. The control system records data for detailed test reports.

7. The Blowing Rain Test Chamber drains and dries between tests.

Why Choose Xi'an LIB Environmental Simulation Industry

1. Proven Quality Standards

We follow ISO 9001 Quality Management System rigorously. All products carry CE certification and third-party testing from SGS and TUV. This ensures international compliance, stable performance, and high reliability.

2. Exceptional Service Support

Every Blowing Rain Test Chamberincorporates a comprehensive 3-year guarantee also lifetime benefit. Our 24/7 worldwide back arrange reacts rapidly to your needs. If repair isn't conceivable amid guarantee, we give brand-new substitution equipment.

3. Custom Solutions Expertise

Our building group exceeds expectations at non-standard plans and custom advancement. We make custom fitted arrangements that coordinate your particular testing prerequisites perfectly.