Accelerated Weathering Tests: How Long Should They Run?

Accelerated Weathering Tests: How Long Should They Run?

Determining the proper duration for accelerated weathering tests remains one of the most critical decisions in material qualification. The answer depends on several interconnected factors: your testing objectives, material composition, industry requirements, target irradiance dose, and correlation models between laboratory conditions and real-world exposure. Generally, basic screening tests may run 300-1,000 hours, while comprehensive durability studies extend from 2,000 to 5,000 hours or beyond. Understanding these parameters ensures your weatherometer chamber delivers meaningful, actionable data rather than arbitrary numbers.

Defining Test Goals: Pass/Fail Verification vs. Lifetime Prediction

Understanding Binary Assessment Requirements

Pass/fail testing establishes whether materials meet minimum performance thresholds. This approach typically requires shorter test durations, ranging from 500 to 1,500 hours in a weatherometer chamber. Manufacturers use these protocols when validating that formulations meet specified retention values for color stability, gloss, or mechanical properties. The test concludes once materials either exceed acceptable degradation limits or successfully maintain properties above threshold requirements.

Predictive Modeling for Service Life Estimation

Lifetime prediction demands substantially longer exposure periods with multiple inspection intervals. These tests extend from 2,000 to 6,000 hours, generating degradation curves that project long-term performance. Engineers extract kinetic data at various timepoints, establishing mathematical relationships between exposure dose and property changes. This methodology transforms weatherometer chamber data into forecasts spanning years or decades of outdoor service.

Strategic Planning Based on Development Stage

Product development stage significantly influences duration selection. Early-stage formulation screening employs abbreviated cycles of 300-800 hours to rapidly eliminate poor candidates. Mid-stage development testing increases to 1,500-3,000 hours for comparative analysis. Final qualification testing often mandates 3,000-5,000 hours, providing robust datasets for regulatory submissions and warranty validation. Aligning test length with development milestones optimizes resource allocation while maintaining data quality.

How Material Type and Formulation Influence Duration?

Polymer Structure and Stabilizer Systems

Polymer chemistry fundamentally affects required test duration. Materials containing aromatic structures degrade faster under UV radiation, potentially showing significant changes within 500-1,000 hours. Conversely, aliphatic polymers with robust stabilizer packages may require 3,000-5,000 hours before observable degradation occurs. The weatherometer chamber must operate long enough to challenge even well-protected formulations, revealing potential weaknesses that emerge only after extended exposure.

Pigmentation and Opacity Effects

Color and opacity dramatically alter degradation kinetics. Dark pigments absorb more radiant energy, elevating surface temperatures and accelerating thermal degradation processes. These materials often exhibit measurable changes within 800-1,500 hours. Light-colored or transparent materials distribute absorbed energy differently, potentially requiring 2,000-4,000 hours for equivalent degradation levels. Pigment selection therefore directly impacts economical test duration planning.

Composite and Multi-Layer Systems

Complex assemblies demand longer evaluation periods than single-component materials. Automotive clearcoat systems, architectural laminates, and textile composites involve multiple interfaces where degradation mechanisms interact. Each layer may respond differently to UV radiation, temperature, and moisture cycling. Comprehensive assessment of these systems typically requires 2,500-5,000 hours in a weatherometer chamber to observe delamination, intercoat adhesion loss, or migration phenomena.

The Role of Industry Standards (ASTM G155, ISO 4892) in Setting Hours

Standard Test Method Specifications

Standard | Application | Typical Duration | Irradiance Level |

ASTM G155 Cycle 1 | General polymers | 1,000-2,000 hours | 0.35 W/m²@340nm |

ISO 4892-2 Method A | Automotive coatings | 2,000-3,000 hours | 60 W/m²@300-400nm |

SAE J2527 | Automotive interiors | 450-2,000 kJ/m² | 0.55 W/m²@340nm |

ASTM G155 and ISO 4892 provide foundational methodologies for xenon arc weathering, specifying light intensity, temperature settings, and moisture cycling. These standards often suggest minimum durations but emphasize dose-based approaches. Material specifications frequently reference these methods, establishing contractual requirements. Understanding standard protocols ensures weatherometer chamber operation aligns with industry expectations and facilitates cross-laboratory comparisons.

Industry-Specific Requirements Beyond Base Standards

Automotive OEMs impose requirements exceeding basic ASTM or ISO protocols. Ford FLTM BO 116-01 and GM 9125P specify unique cycles and extended durations reaching 3,000-4,000 hours. Architectural coatings face AAMA 2605 requirements mandating specific Florida exposure correlation. Textile producers reference AATCC standards with duration determined by end-use colorfastness grades. Compliance testing must match these sector-specific protocols precisely, driving duration selection beyond generic recommendations.

Flexibility for Research Applications

While standards provide valuable frameworks, research and development applications often benefit from customized durations. Comparative studies evaluating formulation changes may use abbreviated protocols when relative performance matters more than absolute endurance. Failure analysis investigations might extend tests far beyond standard durations to understand degradation endpoints. The weatherometer chamber serves as a flexible tool, with duration tailored to specific technical questions rather than rigid adherence to prescriptive timeframes.

Determining the Appropriate Total Irradiance Dose (J/m²)

Dose-Based Versus Time-Based Approaches

Modern weathering science emphasizes radiant exposure dose measured in joules per square meter rather than simple clock hours. A 2,000-hour test at 0.35 W/m²@340nm delivers approximately 2,520 MJ/m², while the same duration at 0.70 W/m² doubles the dose to 5,040 MJ/m². Dose-based planning accounts for intensity variations, equipment capabilities, and desired acceleration factors. Weatherometer chamber programming should prioritize dose accumulation targets, ensuring consistent comparison across different facilities or lamp aging conditions.

Calculating Required Dose from Outdoor Correlation

Location | Annual Dose (MJ/m²@340nm) | Equivalent Chamber Hours |

Miami, Florida | 950-1,100 | 1,350-1,550 |

Phoenix, Arizona | 800-950 | 1,150-1,350 |

Northern Europe | 400-550 | 570-785 |

Calculated at 0.55 W/m²@340nm irradiance

Outdoor exposure data establishes baseline dose requirements. Surfaces in subtropical climates accumulate approximately 950-1,100 MJ/m² annually at 340nm wavelength. Materials requiring five-year outdoor validation need weatherometer chamber testing delivering 4,750-5,500 MJ/m² total dose. Converting these values to test hours depends on selected irradiance intensity. Higher intensity settings reduce duration but may introduce unrealistic degradation mechanisms if acceleration exceeds reasonable limits.

Balancing Acceleration and Realism

Excessive irradiance intensity accelerates testing but risks non-linear degradation responses. Most protocols maintain 0.35-0.70 W/m²@340nm, representing 3-6 times average midday subtropical intensity. This moderate acceleration preserves degradation mechanism fidelity while achieving reasonable test durations. Ultra-high intensity approaches exceeding 1.0 W/m² may complete tests faster but can produce anomalous results not representative of actual outdoor performance. Prudent weatherometer chamber operation balances time efficiency against data validity.

Using Performance Benchmarks and Interim Inspections to Decide

Establishing Endpoint Criteria

Clear performance benchmarks define when testing achieves sufficiency. Color change specifications might target ΔE ≤ 2.0 units, while gloss retention requires maintaining 85% of initial 60° measurements. Mechanical property tests may specify maximum tensile strength loss of 20%. Once materials approach these thresholds, testing reaches meaningful conclusions. Rather than arbitrary duration targets, criterion-based endpoints ensure weatherometer chamber operation continues only until obtaining decisive results.

Implementing Staged Inspection Protocols

Test Duration Range | Inspection Intervals | Assessment Type |

0-1,000 hours | Every 250 hours | Visual, colorimetry |

1,000-2,500 hours | Every 500 hours | Visual, colorimetry, gloss |

2,500+ hours | Every 1,000 hours | Full property suite |

Regular interim evaluations provide progressive degradation profiles. Initial inspections at 250-500 hour intervals capture early-stage changes, revealing rapid-failure materials. Mid-test assessments every 500-1,000 hours track degradation kinetics, informing decisions about extending or concluding tests. This staged approach prevents unnecessary over-testing while ensuring adequate exposure for slower-degrading formulations. The weatherometer chamber becomes an adaptive tool rather than a fixed-duration instrument.

Comparative Testing with Control Materials

Including reference materials with known performance characteristics provides context for duration decisions. When test samples reach degradation levels matching historical controls at their typical endpoints, comparable exposure sufficiency exists. This benchmarking approach proves especially valuable when evaluating reformulations or testing new material classes without established protocols. Control materials transform subjective duration judgments into objective, performance-anchored decisions.

Correlating Accelerated Hours to Months or Years of Outdoor Exposure

Understanding Acceleration Factors

Acceleration factors quantify the relationship between weatherometer chamber exposure and real-world aging. Typical xenon arc testing achieves 5-8× acceleration compared to subtropical outdoor exposure, though values vary by material type and degradation mechanism. A 2,000-hour laboratory test potentially represents 10,000-16,000 hours outdoors, equivalent to 12-20 months. These factors depend on geographic location, mounting angle, and seasonal variations affecting actual outdoor dose accumulation.

Geographic and Application-Specific Considerations

Correlation factors shift substantially across deployment environments. Materials serving in southern Arizona experience roughly 30% higher annual UV dose than identical products in northern Germany. Vertical automotive surfaces receive different spectral distributions than horizontal roofing materials. Weatherometer chamber conditions typically simulate direct equator-facing exposure at 5° from horizontal. Converting chamber hours to service life predictions requires adjusting for actual installation geometry and location-specific solar radiation patterns.

Limitations and Confidence Intervals

Laboratory-to-outdoor correlations involve inherent uncertainty. Even well-established relationships typically exhibit ±30% variability due to batch variations, micro-climate effects, and test reproducibility limits. A weatherometer chamber prediction of 5-year durability should be interpreted as 3.5-6.5 years with appropriate confidence intervals. This uncertainty underscores the importance of combining accelerated testing with limited outdoor exposure validation, creating hybrid protocols that leverage laboratory efficiency while grounding predictions in real-world performance data.

LIB Weatherometer: Intelligent Testing for Optimal Duration

Advanced Control Systems for Precision Testing

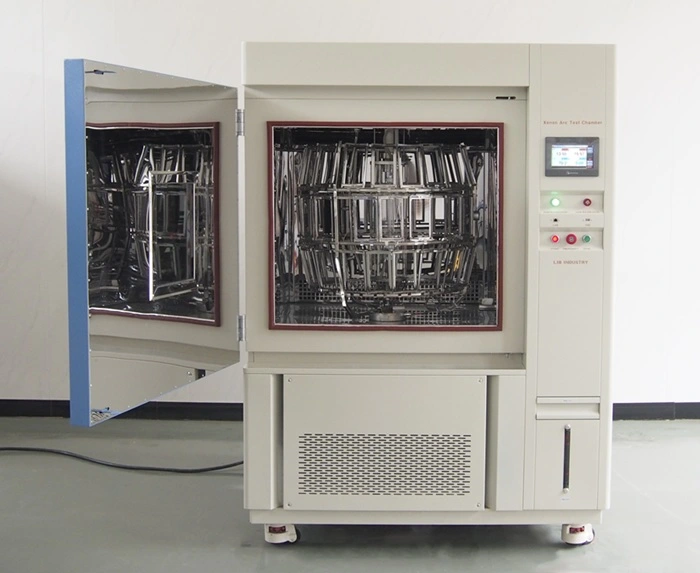

The LIB weatherometer chamber incorporates programmable color LCD touch screen controllers enabling precise test duration management. Users can program complex exposure cycles combining light, dark, water spray, and humidity phases extending from minutes to 9,999 hours. The integrated UV radiometer with ±5% tolerance ensures consistent dose delivery throughout extended test campaigns. This precision control eliminates the guesswork from duration planning, converting theoretical dose calculations into reliable, repeatable test executions.

Flexible Configuration Supporting Diverse Protocols

Housing 42 specimens in rotating holders around a 4500W water-cooled xenon arc lamp, the XL-S-750 model accommodates parallel testing of multiple formulations or protocol comparisons. The 35-150 W/m² irradiance range supports both gentle simulation and highly accelerated protocols. Chamber temperature control spanning ambient to 100°C, combined with 50-98% RH humidity management, replicates diverse climatic conditions. This versatility allows researchers to optimize test duration by selecting acceleration levels matching material sensitivity and project timelines.

Automated Operation Reducing Duration Uncertainty

Automatic water supply and purification systems maintain consistent spray simulation throughout multi-month test campaigns. Over-temperature, water shortage, and phase sequence protection features prevent mid-test failures that would invalidate long-duration experiments. External stainless steel evaporation humidification ensures stable moisture delivery during 3,000+ hour protocols. These automation features transform the weatherometer chamber from a supervised instrument into an autonomous testing platform, enabling extended duration studies without constant operator intervention or data quality concerns.

Conclusion

Accelerated weathering test duration decisions blend scientific principles with practical constraints. Material characteristics, testing objectives, standard requirements, dose calculations, and correlation models collectively inform appropriate timeframes. Most applications settle between 1,000-4,000 hours, balancing thorough evaluation against schedule realities. Implementing staged inspection protocols and dose-based planning transforms duration selection from guesswork into strategic methodology, ensuring weatherometer chamber operation delivers maximum value.

FAQs

Can I shorten test duration by increasing irradiance intensity?

While higher intensity reduces hours, excessive acceleration above 0.70 W/m²@340nm may produce unrealistic degradation patterns. Maintain moderate intensity levels to preserve mechanism fidelity while achieving reasonable timeframes through dose-based planning rather than extreme acceleration.

How do I know if my test ran long enough?

Adequate duration is achieved when materials either reach specified performance thresholds or accumulate target doses based on outdoor correlation. Implement interim inspections tracking degradation progression rather than relying solely on predetermined hour counts disconnected from actual material response.

Do all materials in the same weatherometer chamber require identical duration?

Different materials degrade at varying rates, so multi-material testing may require staggered removal. Some specimens reach endpoints at 1,500 hours while others need 4,000+ hours. Plan inspection schedules accommodating different degradation kinetics rather than forcing uniform duration across dissimilar materials.

As a leading weatherometer chamber manufacturer and supplier, LIB Industry delivers comprehensive testing solutions backed by technical expertise. Our team helps optimize test duration protocols specific to your materials and objectives.