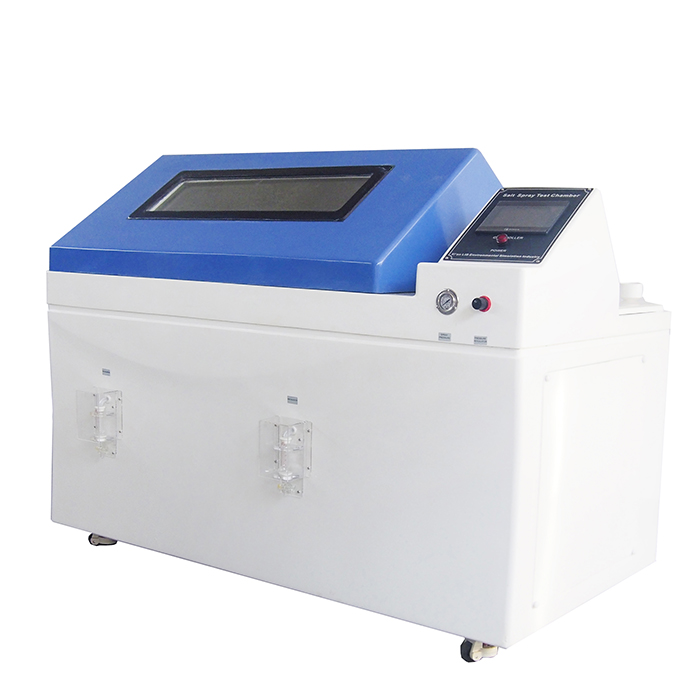

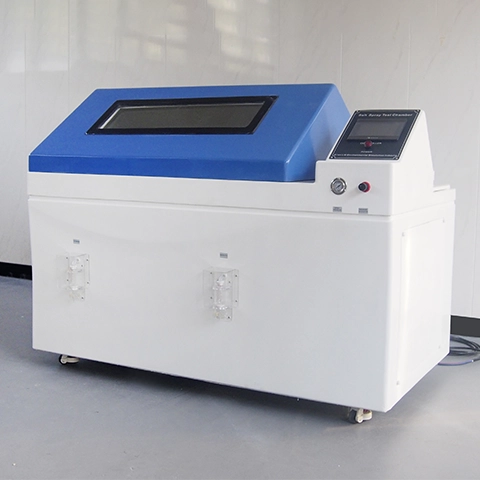

JIS Z 2371 Salt Spray Test Chamber

Temperature Range:Ambient: ~ +60 ℃

Humidity Range:95% ~ 98% RH

Temperature Deviation:± 2.0 ℃

Salt Fog Deposition:1~2ml / 80cm2 · h

Spray Type: Continuous / Periodic

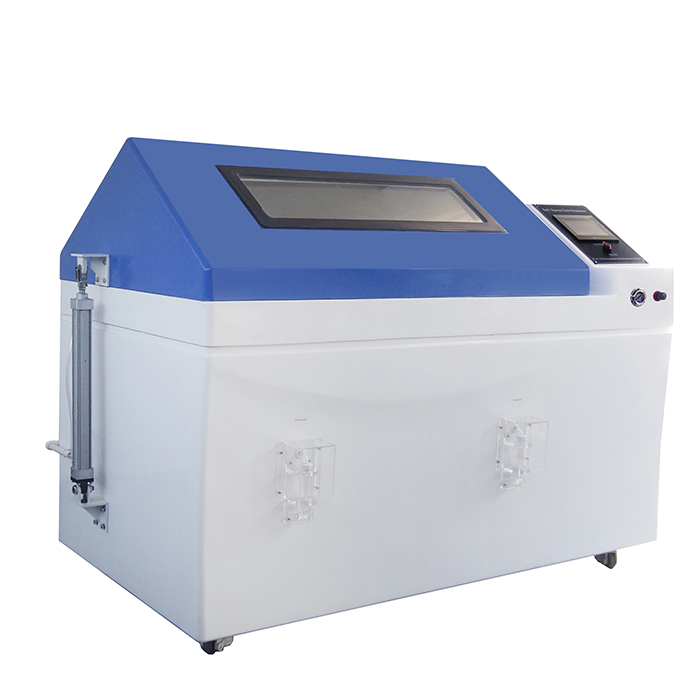

Materials: Glass fiber reinforced plastics

- Product Description

JIS Z 2371 Salt Spray Test Chamber Manufacturer & Supplier

JIS Z 2371 Salt Spray Test Chamber is designed to simulate and evaluate the effects of corrosion on various materials and coatings. At LIB Industry, we standard and customized salt spray corrosion chambers catering to diverse industry needs.

Our salt spray corrosion chambers offer precise control over testing conditions, ensuring accurate and repeatable results. They facilitate the assessment of a material's corrosion resistance, allowing for comprehensive analysis and data-driven decision-making in material selection and development.

Technical Specifications

Model | S-150 | S-250 | S-750 | S-010 | S-016 | S-020 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 | 900*1600*720 | 1000*2000*800 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 | 2300×1300×1700 | 2700×1300×1900 |

Interior Volume (L) | 110 | 320 | 410 | 780 | 1030 | 1600 |

Temperature Range | Ambient ~ +60 ℃ | |||||

Temperature Fluctuation | ± 0.5 ℃ | |||||

Temperature Deviation | ± 2.0 ℃ | |||||

Humidity Range | 95% ~ 98% RH | |||||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||||

Spray Type | Continuous / Periodic | |||||

Salt Fog Collected | Fog collector and fog measure cylinder | |||||

Air Preheating | Saturated air barrel | |||||

Spraying System | Atomizer tower and Spray nozzles | |||||

Controller | PID controller | |||||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||||

Material | Glass fiber reinforced plastics | |||||

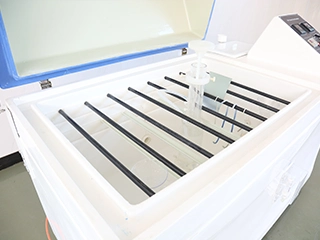

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||||

Product Details

|

|

|

| Salt Water Tank Built-in salt solution tank and external salt water tank Brine mixing system to keep the salt solution even | Salt Spray Nozzle Salt spray nozzles are easy to clean and resistant to high temperatures, corrosion, and clogging | Sample shelf Standard sample holder contains 6 round bars and 5 V-shaped grooves for different tests. Special holders can be customized |

|

|

Deep Compliance with JIS Z 2371 Standards

1. Multi-Test Type Support

Our chamber underpins all three center testing strategies characterized by JIS Z 2371:

· Neutral Salt Spray (NSS)- Standard corrosion resistance testing

· Acetic Acid Salt Spray (AASS)- Enhanced acidic environment simulation

· Copper Accelerated Cyclic Test (CASS)- Advanced accelerated corrosion testing

2. Precision pH Control System

Meeting JIS requirements for pH accuracy is basic. Our framework keeps up NSS pH levels between 6.5-7.2 with helpful testing ports for simple confirmation. The accuracy salt water planning tank guarantees steady chemical composition all through amplified testing periods.

Japanese-Style Precision Engineering

1. Advanced Air Saturator Design

The soaked discuss tower employments premium SUS304/316 stainless steel development. This framework accurately humidifies and warms compressed discuss, disposing of natural contaminants whereas guaranteeing uniform dampness dispersion. Temperature control precision comes to ±0.1°C.

2. Dual Temperature Control System

Independent chamber and research facility temperature controls avoid outside obstructions. Multi-layer separator keeps up steady inner conditions whereas separating encompassing temperature fluctuations.

3. Precise Sample Positioning

Pre-calibrated V-type and O-type test holders keep up correct 15° or 20° points as indicated by JIS measures. No manual alterations required - fair position your tests and begin testing.

4. Settlement Collection System

Movable funnel collectors can be positioned anywhere within the JIS Z 2371 Salt Spray Test Chamber. This flexibility ensures accurate measurement of the required 1.0-2.0ml settlement rate regardless of sample placement.

5. Advanced Control & Safety Features

Our programmable controller bolsters 120 programs with 100 steps each. You can plan persistent or cyclic splash designs whereas naturally recording temperature, splash term, and settlement information. This makes audit-ready reports that fulfill traceability requirements. The programmed water refill framework avoids dry-running harm. When water levels drop underneath security limits, the framework naturally stops operation and cautions operators.

6. Long-Duration Testing Capability

The insides FRP (Fiberglass Strengthened Plastic) development withstands persistent presentation to 5% NaCl arrangements beneath tall temperature and stickiness conditions. This fabric choice guarantees solid operation amid tests enduring hundreds or thousands of hours. The altered V-shaped straightforward top avoids condensation from dribbling onto test tests. This plan keeps up test legitimacy all through expanded cycles whereas lessening upkeep frequency.

Why Choose Our Solution

1. Professional Quality: All units take after ISO 9001 measures with CE certification. Third-party testing by SGS and TUV affirms worldwide compliance and dependable performance.

2. Service Affirmation: Each chamber incorporates a 3-year guarantee with lifetime benefit back. Our 24/7 worldwide bolster group gives fast reaction, and we offer total unit substitution if repairs aren't conceivable amid guarantee periods.

3. Customization Skill: Our building group specializes in non-standard plans and custom improvement. We make custom fitted arrangements that coordinate your particular testing prerequisites and industry applications.