Printed circuit boards (PCBs) used in outdoor electronics, automotive systems, and aerospace applications are often exposed to ultraviolet light, which can accelerate material aging and impact long-term reliability. UV resistance test chambers allow manufacturers to simulate UV radiation along with controlled temperature and humidity, providing a laboratory environment to evaluate the durability of PCB substrates, solder masks, and protective coatings before market release.

The chamber's effectiveness has been confirmed in real-world use, with customer feedback highlighting smooth and reliable operation during daily testing. This demonstrated stability makes the UV resistance test chamber an essential tool in PCB qualification, ensuring consistent and reproducible results, supporting accelerated aging studies, and helping manufacturers meet industry testing standards.

Plastic weathering evaluation requires precision testing equipment that accurately simulates outdoor environmental conditions. ASTM G154 UV test machines provide controlled exposure to ultraviolet radiation, moisture, and temperature fluctuations, enabling manufacturers to assess material durability before real-world deployment. These chambers replicate years of outdoor degradation within weeks, offering accelerated insights into color stability, mechanical strength retention, and surface integrity. Through standardized testing protocols, engineers can validate plastic formulations, optimize additive packages, and ensure product longevity across diverse climatic zones.

Why UV Exposure Is a Key Factor in Plastic Degradation?

Ultraviolet radiation represents one of the most destructive environmental forces affecting polymer materials. Understanding the mechanisms behind UV-induced degradation enables better material selection and protective strategies.

mechanisms behind UV-induced degradation enables better material selection and protective strategies.

Photochemical Bond Cleavage in Polymer Chains

UV photons carry sufficient energy to break chemical bonds within polymer backbones. When wavelengths between 290-400 nanometers strike plastic surfaces, they initiate photolytic reactions that sever carbon-carbon and carbon-hydrogen bonds. This chain scission reduces molecular weight, compromising mechanical properties and structural integrity. Polypropylene and polyethylene exhibit particular vulnerability, as their aliphatic structures absorb UV energy readily.

Free Radical Formation and Oxidative Cascades

Absorbed UV energy generates free radicals that trigger autocatalytic degradation cycles. These highly reactive species react with atmospheric oxygen, creating peroxy radicals that propagate throughout the polymer matrix. The resulting oxidative cascade continues even after UV exposure ceases, causing progressive embrittlement and discoloration. Antioxidant additives can interrupt these chain reactions, but their effectiveness diminishes over extended exposure periods.

Surface Layer Deterioration and Chalking

UV radiation concentrates its effects within the first 50-100 micrometers of plastic surfaces. This selective degradation creates a fragile outer layer that exhibits chalking, cracking, and loss of gloss. Pigments and fillers become exposed as the polymer binder degrades, leading to the characteristic whitish powder appearance. Surface roughness increases dramatically, altering both aesthetic appeal and functional properties like friction coefficients.

Overview of ASTM G154 Plastic Weathering Test Methods

ASTM G154 establishes comprehensive protocols for evaluating material resistance to UV light and condensation exposure. These standardized procedures ensure reproducible results across different laboratories and testing facilities.

standardized procedures ensure reproducible results across different laboratories and testing facilities.

Cycle Configuration Options for Different Exposure Scenarios

The standard defines multiple test cycles tailored to specific material applications and geographic conditions. Cycle 1 alternates eight hours of UV exposure at 60°C with four hours of condensation at 50°C, simulating typical subtropical environments. Cycle 4 reduces UV exposure to four hours followed by four hours of condensation, representing moderate climates with significant dew formation. Cycle 6 incorporates water spray during UV exposure, replicating tropical conditions with concurrent rain and sunshine.

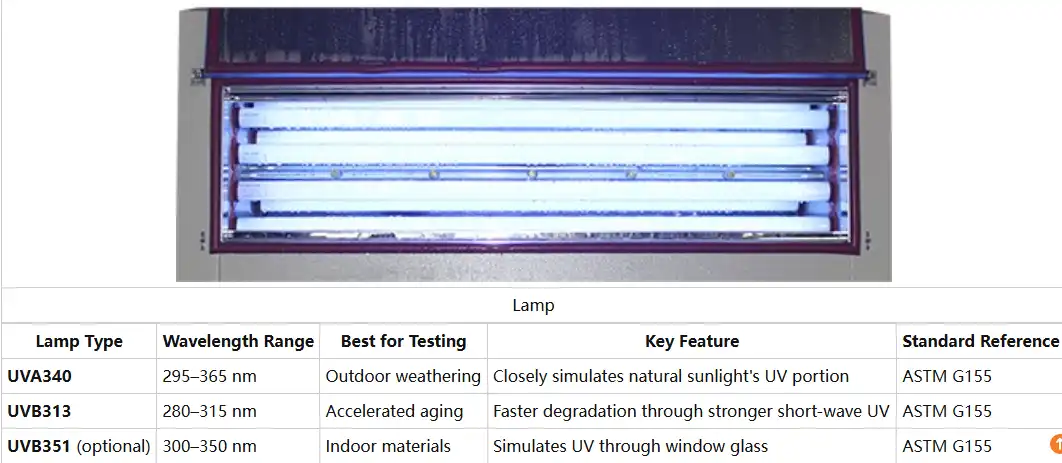

UVA-340 Versus UVB-313 Lamp Selection Criteria

UVA-340 lamps reproduce the solar spectrum's short-wavelength UV region most accurately, making them ideal for predicting real-world outdoor durability when used in a UV test machine. These lamps generate peak emission at 340 nanometers, matching the critical degradation wavelengths experienced in natural sunlight. UVB-313 lamps deliver more aggressive exposure with peak output at 313 nanometers, accelerating degradation for comparative material screening. While UVB-313 testing reduces test duration, it may produce degradation patterns not observed in actual service conditions.

Specimen Mounting and Exposure Uniformity Requirements

Proper specimen positioning ensures consistent irradiance across all test samples. ASTM G154 mandates maintaining specimens at 50 millimeters distance from lamp surfaces, with periodic rotation to compensate for intensity variations. Sample holders accommodate flat panels measuring 75×150 millimeters, allowing 56 simultaneous specimens per chamber. Black panel temperature sensors monitor surface conditions, providing feedback for precise environmental control throughout extended test campaigns.

ASTM G154 Test Cycle | UV Exposure Duration | Condensation Duration | Black Panel Temperature | Typical Application |

Cycle 1 | 8 hours | 4 hours | 60°C | General outdoor products |

Cycle 4 | 4 hours | 4 hours | 50°C | Moderate climate exposure |

Cycle 6 | 8 hours (with spray) | 4 hours | 60°C | Tropical environments |

UV Lamp Types and Irradiance Control in Weathering Tests

Selecting appropriate UV sources and maintaining precise irradiance levels constitute critical factors in weathering test validity. Advanced control systems ensure consistent exposure conditions throughout multi-week test campaigns.

Spectral Power Distribution Matching Natural Sunlight

UVA-340 lamps achieve excellent correlation with terrestrial solar UV spectrum between 295-365 nanometers. This spectral match ensures that laboratory-induced degradation mechanisms mirror outdoor weathering processes. The lamps utilize special phosphor coatings that emit a continuous spectrum rather than discrete spectral lines, eliminating artificial acceleration effects caused by non-representative wavelengths. Regular spectral radiometer measurements verify maintained spectral output throughout lamp service life.

Irradiance Monitoring Systems and Calibration Procedures

Modern weathering chambers incorporate feedback-controlled irradiance systems that compensate for lamp aging automatically. Silicon photodetector sensors measure UV intensity continuously, adjusting electrical input to maintain target irradiance levels within ±2% tolerance. Annual calibration against traceable reference radiometers ensures measurement accuracy. The UV-SI-260 model provides adjustable irradiance from 0.3 to 20 W/m², accommodating both standard protocols and customized exposure intensities.

Lamp Replacement Strategies for Consistent Results

Fluorescent UV lamps experience gradual output degradation, typically declining 20-30% after 1,600 operational hours. Replacing all lamps simultaneously when any single lamp reaches end-of-life prevents irradiance variations between test batches. Documenting lamp installation dates and operating hours enables proactive maintenance scheduling. The built-in lamp management system tracks cumulative exposure time and generates replacement alerts, preventing unexpected test interruptions.

Evaluating Color, Mechanical, and Surface Changes in Plastics

Comprehensive weathering assessment requires measuring multiple degradation parameters that correlate with end-use performance failures, typically conducted using an ASTM G154 UV test machine. Combining colorimetric, mechanical, and surface analysis provides complete material characterization.

Colorimetric Analysis Using CIELAB Color Space

Spectrophotometric measurements quantify color changes through standardized CIELAB coordinates. The ΔE parameter combines lightness (ΔL), red-green (Δa), and blue-yellow (Δb) shifts into a single numerical value representing total color difference. Automotive specifications typically limit ΔE to 1.0 for body panels, while building materials may permit ΔE values up to 5.0 before visible degradation becomes objectionable. Measurements at multiple exposure intervals reveal degradation kinetics and help establish failure criteria.

Tensile Strength and Elongation Retention Testing

Mechanical property measurements assess structural degradation beyond visible changes. Tensile testing per ASTM D638 reveals both strength reduction and embrittlement through decreased elongation at break. Materials losing more than 50% of initial elongation typically exhibit microcracking and are considered failed. Impact resistance measured by ASTM D256 detects brittle failure tendencies before catastrophic service failures occur. Comparing exposed versus unexposed specimens quantifies degradation severity.

Gloss Reduction and Surface Roughness Profiling

Specular gloss measurements at 60-degree incident angles track surface deterioration objectively. High-gloss materials showing greater than 50% gloss loss typically exhibit visible chalking and require reformulation. Contact profilometry measures surface roughness increases resulting from UV-induced matrix erosion. Ra (average roughness) values increasing from 0.1 to 2.0 micrometers indicate significant surface degradation. These measurements correlate strongly with field performance in architectural and automotive applications.

Property Measurement | Test Method | Typical Failure Criterion | Testing Frequency |

Color Change (ΔE) | ASTM D2244 | ΔE > 3.0 | Every 250 hours |

Tensile Strength | ASTM D638 | >25% reduction | Every 500 hours |

Elongation at Break | ASTM D638 | >50% reduction | Every 500 hours |

Gloss Retention | ASTM D523 | <50% of initial | Every 250 hours |

Impact Strength | ASTM D256 | >30% reduction | Every 500 hours |

Test Cycle Selection for Different Plastic Materials

Material composition, intended application environment, and performance requirements dictate optimal test cycle selection. Matching laboratory conditions to anticipated service exposure maximizes predictive accuracy.

Polyolefin Testing Protocols for Outdoor Furniture

Polypropylene and polyethylene products designed for outdoor furniture require extended UV exposure cycles that emphasize photodegradation over moisture effects. Cycle 1 with continuous eight-hour UV periods at maximum irradiance accelerates the free radical oxidation characteristic of polyolefin degradation. Adding heat stabilizers and UV absorbers can extend service life from months to years, with laboratory testing compressing this timeframe into weeks.

Polycarbonate and Acrylic Glazing Material Evaluation

Transparent plastics demand special attention to optical property retention alongside mechanical performance when evaluated using an ASTM G154 UV test machine. Modified Cycle 4 with reduced black panel temperatures prevents thermal yellowing that would confound UV degradation assessment. Light transmission measurements complement color change analysis, ensuring glazing materials maintain required optical clarity. Haze measurements detect subsurface microcracking before visible crazing develops.

Engineering Thermoplastics for Automotive Applications

Polyamides, polybutylene terephthalate, and acrylonitrile-butadiene-styrene copolymers face combined UV, thermal, and moisture stresses in automotive environments. Cycle 6 incorporating simultaneous UV and water spray replicates the thermal shock experienced during summer rainstorms. Testing at elevated irradiance levels (1.55 W/m² at 340nm) compresses multi-year service exposure into 2,000-3,000 hour test campaigns.

Using Weathering Data to Predict Plastic Service Life

Translating accelerated laboratory exposure into real-world durability predictions requires careful correlation studies and statistical modeling. Validated prediction methods enable confident material selection and warranty establishment.

prediction methods enable confident material selection and warranty establishment.

Correlation Factors Between Laboratory and Outdoor Exposure

Establishing site-specific correlation ratios demands parallel exposure of reference materials in weathering chambers and outdoor test locations. Florida subtropical exposure typically correlates to laboratory testing at 5:1 to 8:1 acceleration factors, meaning 1,000 chamber hours approximate one year outdoors. Northern European climates show 10:1 to 15:1 correlations due to lower annual UV dosage. Geographic location, seasonal variations, and material-specific responses all influence correlation accuracy.

Arrhenius Modeling for Temperature-Dependent Degradation

Temperature acceleration follows Arrhenius kinetics, allowing mathematical extrapolation of degradation rates. Conducting identical UV exposure cycles at multiple black panel temperatures generates activation energy values for specific material formulations. These parameters enable predicting degradation rates at any service temperature within tested ranges. Polyethylene typically exhibits activation energies between 80-120 kJ/mol, while polycarbonate shows 60-90 kJ/mol due to different degradation mechanisms.

Reciprocity Principle Application and Limitations

The reciprocity principle assumes equivalent degradation from equal total UV dosage regardless of intensity or duration. While valid for many materials under moderate conditions, reciprocity failures occur at extreme irradiance levels or with photosensitive additives. Testing at 2-3× outdoor intensity generally maintains reciprocity, but 10× acceleration may produce non-representative failure modes. Validating reciprocity through dose-response studies prevents overly optimistic service life predictions.

Geographic Location | Annual UV Dosage (MJ/m²) | Acceleration Factor (vs Lab) | Equivalent Test Duration |

South Florida | 450-500 | 5:1 to 7:1 | 1000-1400 hours/year |

Arizona Desert | 500-550 | 5:1 to 6:1 | 900-1200 hours/year |

Northern Europe | 200-250 | 12:1 to 15:1 | 2400-3600 hours/year |

Tropical Asia | 400-450 | 6:1 to 8:1 | 1200-1600 hours/year |

Reliable Degradation Analysis with LIB Industry ASTM G154 UV Test Machines

Advanced weathering chambers combining precision environmental control with user-friendly operation enable efficient material development and quality assurance programs. The UV-SI-260 model delivers laboratory-grade performance for demanding applications.

Eight-Lamp Configuration for Uniform Irradiance Distribution

The UV-SI-260 employs eight 40-watt fluorescent UV lamps arranged in a parallel configuration that eliminates center-to-edge intensity variations. This geometry ensures all 56 specimen positions receive equivalent UV dosage, preventing position-dependent result variations that compromise statistical validity. Reflective interior surfaces maximize lamp efficiency while maintaining spectral distribution. The 50-millimeter lamp-to-specimen distance balances irradiance uniformity against chamber capacity.

Integrated Condensation and Water Spray Systems

Realistic moisture exposure requires both condensation and direct water impingement capabilities. The condensation cycle saturates chamber atmosphere while maintaining specimen surfaces at elevated temperature, replicating outdoor dew formation. Ten precision nozzles deliver controlled water spray at 0.8-1.0 mm/80cm² per hour, creating thermal shock conditions that accelerate cracking and delamination. Automated water purification prevents mineral deposits that would interfere with UV transmission.

Programmable Touch Screen Controller with Data Logging

The color LCD interface simplifies test setup through pre-programmed ASTM G154 cycle templates requiring only exposure duration entry. Custom cycles accommodate non-standard protocols with independent UV, condensation, and spray period settings. Real-time parameter monitoring displays current chamber temperature, irradiance, and humidity alongside target values. Ethernet connectivity enables remote monitoring and automatic data export for analysis in spreadsheet or statistical software packages.

Conclusion

ASTM G154 UV test machines provide essential capabilities for evaluating plastic weathering resistance through controlled laboratory exposure. Proper lamp selection, cycle configuration, and property assessment techniques enable accurate service life predictions that guide material development and quality control decisions. The UV-SI-260 chamber delivers research-grade performance with operational simplicity that supports both routine testing and advanced material characterization studies.

FAQs

How long does ASTM G154 testing typically require to predict one year of outdoor exposure?

Testing duration depends on geographic location and material type, but generally ranges from 1,000 to 2,000 chamber hours to simulate one year of outdoor exposure in subtropical climates. Northern climates may require longer test periods due to lower UV intensity correlation factors.

Can ASTM G154 testing predict performance in extreme environments like deserts or high altitudes?

Standard ASTM G154 cycles simulate typical outdoor conditions but may underestimate degradation in extreme environments. Custom test cycles with elevated irradiance levels and extended UV exposure periods better represent desert or high-altitude conditions where UV intensity exceeds sea-level subtropical exposure.

What maintenance requirements ensure consistent ASTM G154 test results over time?

Regular lamp replacement after 1,600 operating hours maintains consistent irradiance levels. Annual radiometer calibration verifies measurement accuracy. Water purification system maintenance prevents mineral buildup that reduces UV transmission. Temperature sensor calibration every two years ensures accurate black panel temperature control.

Contact LIB Industry for UV Testing Solutions

LIB Industry manufactures precision environmental test chambers serving global material testing laboratories. Our ASTM G154 UV weathering systems combine standardized testing capabilities with customizable features tailored to specific application requirements. Contact our technical team at ellen@lib-industry.com to discuss your plastic weathering evaluation needs and receive detailed equipment specifications.