In the highly competitive beverage industry, ensuring consistent product quality is crucial. Shelf life test chambers provide precise control over temperature and humidity, replicating real-world storage conditions—from hot warehouses to refrigerated distribution networks. These controlled environments allow manufacturers to assess flavor stability, carbonation retention, microbial activity, and packaging performance, helping guarantee that every bottle, can, or carton meets consumer expectations throughout its shelf life.

A client from Russia, specializing in instrumentation, commented: “Our LIB temperature cycling chamber works flawlessly. Everything is perfect, and the chamber performs exactly as expected.” Feedback like this highlights the reliability and efficiency of LIB chambers in supporting beverage quality assurance across diverse global applications.

Temperature cycling tests reveal thermal fatigue failures by subjecting materials and components to repeated heating and cooling cycles that mirror real-world operational stresses. Through controlled temperature transitions, these tests accelerate degradation mechanisms that would otherwise take years to manifest. A temperature cycling chamber monitors critical failure indicators including solder joint cracking, delamination, material embrittlement, and interfacial separation. By precisely controlling ramp rates, dwell times, and temperature extremes, engineers can pinpoint the exact conditions where thermal expansion mismatches overwhelm material integrity, allowing manufacturers to redesign vulnerable components before costly field failures occur.

What Is Thermal Fatigue and How It Affects Materials?

The Physics Behind Thermal Expansion and Contraction

Materials expand when heated and contract during cooling - a fundamental physical property governed by their coefficient of thermal expansion (CTE). When dissimilar materials bond together in assemblies, their different expansion rates create mechanical stress at interfaces. A circuit board with copper traces (CTE: 17 ppm/°C) bonded to ceramic substrates (CTE: 6 ppm/°C) experiences significant stress during temperature swings. Repeated cycling accumulates this stress, progressively weakening molecular bonds until catastrophic failure occurs.

dissimilar materials bond together in assemblies, their different expansion rates create mechanical stress at interfaces. A circuit board with copper traces (CTE: 17 ppm/°C) bonded to ceramic substrates (CTE: 6 ppm/°C) experiences significant stress during temperature swings. Repeated cycling accumulates this stress, progressively weakening molecular bonds until catastrophic failure occurs.

Progressive Damage Accumulation in Components

Thermal fatigue operates through cumulative damage rather than single-event failure. Each temperature transition generates microscopic defects - grain boundary sliding, void formation, and crack initiation. Initially invisible to standard inspection, these defects propagate with continued cycling. Solder joints develop intermetallic compounds that become brittle over time. Polymer adhesives lose cross-linking density. Metallic interconnects develop persistent slip bands that eventually nucleate cracks.

Industry Sectors Most Vulnerable to Thermal Stress

Automotive electronics endure temperature swings from -40°C during winter nights to +125°C under hood conditions. Aerospace components face even harsher extremes during atmospheric transitions. Consumer electronics experience thermal cycling from charging circuits and power management systems. Medical devices requiring sterilization undergo rapid temperature changes. Solar panels withstand daily thermal cycles throughout 25-year service lives. Each industry demands rigorous testing to prevent premature failures.

Mechaniss of Failure During Temperature Cycling

Solder Joint Degradation and Crack Propagation

Solder joints represent the primary failure mode in electronic assemblies subjected to thermal cycling. Lead-free solders (SAC305, SAC405) form brittle intermetallic layers at copper interfaces. During temperature transitions, CTE mismatches between components and circuit boards impose shear stress on these joints. Cracks typically initiate at solder fillet corners where stress concentration is highest. The Coffin-Manson relationship predicts that crack propagation rate follows a power law dependent on temperature range and cycle frequency.

intermetallic layers at copper interfaces. During temperature transitions, CTE mismatches between components and circuit boards impose shear stress on these joints. Cracks typically initiate at solder fillet corners where stress concentration is highest. The Coffin-Manson relationship predicts that crack propagation rate follows a power law dependent on temperature range and cycle frequency.

Delamination at Material Interfaces

Bonded interfaces experience peeling forces when materials with different CTEs expand at different rates. Die attach adhesives separating from substrates, encapsulation materials pulling away from leadframes, and coating layers detaching from base materials all represent delamination failures. Moisture infiltration accelerates this process by weakening interfacial adhesion. Thermal cycling combined with humidity creates the harshest test environment, revealing latent manufacturing defects in bonding processes.

Wire Bond Fatigue and Interconnect Failures

Gold and aluminum wire bonds connecting semiconductor dies to leadframes undergo cyclic flexing during thermal transitions. The wire heel - where bonding occurs - experiences maximum stress concentration. Fatigue cracks develop perpendicular to the wire axis, progressively reducing cross-sectional area until electrical continuity fails. Copper pillar bumps and through-silicon vias in advanced packaging also succumb to thermal fatigue through similar mechanisms.

Key Parameters in Temperature Cycling Tests

Temperature Range Selection Based on Application

Selecting appropriate temperature extremes requires understanding actual operating conditions plus safety margins. Military specifications (MIL-STD-810) mandate -55°C to +125°C for harsh environments. Automotive standards (AEC-Q100) specify -40°C to +150°C for under-hood electronics. Consumer products typically test from -20°C to +85°C. Extended ranges accelerate failure detection but may introduce unrealistic failure modes. The temp cycle chamber must reliably achieve these extremes with precise control.

Application Sector | Typical Low Temp | Typical High Temp | Cycle Duration |

Automotive Electronics | -40°C | +150°C | 30-60 minutes |

Aerospace Components | -55°C | +125°C | 45-90 minutes |

Consumer Electronics | -20°C | +85°C | 15-30 minutes |

Medical Devices | -25°C | +80°C | 20-40 minutes |

Ramp Rate Optimization for Realistic Stress Simulation

The speed of temperature transition dramatically affects failure mechanisms. Slow ramp rates (1-3°C/min) allow thermal equilibrium throughout component mass, simulating gradual environmental changes. Rapid rates (10-15°C/min) create temperature gradients within components, inducing additional thermal shock stress. A temperature cycling chamber with adjustable ramp rates enables engineers to match field conditions precisely. Automotive testing often employs 10°C/min to simulate engine start-up thermal transients.

Dwell Time Configuration and Cycle Count Determination

Dwell periods at temperature extremes allow thermal stabilization and complete phase transformations in materials. Insufficient dwell prevents full expansion/contraction, underestimating real-world stress. Excessive dwell unnecessarily extends test duration. Standard practice maintains 15-30 minute dwells for most applications. Cycle count requirements vary by industry - automotive components may require 1000+ cycles, while aerospace demands 500-2000 cycles depending on mission profiles.

Test Profile Design for Identifying Thermal Weaknesses

Creating Accelerated Life Test Protocols

Accelerated thermal cycling compresses years of field exposure into weeks of testing. Acceleration factors derive from the Arrhenius equation and Coffin-Manson relationships, which relate temperature range and cycle frequency to failure rates. Doubling the temperature range typically increases acceleration by 4-8 times. A well-designed profile balances test duration against failure mode relevance - overly aggressive testing may induce mechanisms that never occur in actual service.

Multi-Stage Profiling for Complex Product Validation

Advanced products require sequential test stages addressing different failure mechanisms. Initial screening at moderate conditions (1000 cycles, ±50°C range) identifies gross manufacturing defects. Subsequent harsh cycling (-40°C to +125°C, 500 cycles) stresses design margins. Final qualification at extreme limits validates reliability boundaries. The temperature cycling chamber programming capability handles complex multi-stage profiles with automatic transitions.

Incorporating Humidity and Vibration for Combined Stress Testing

Real operating environments rarely impose single stressors. Combined thermal-humidity cycling accelerates corrosion and moisture-assisted failures. Adding mechanical vibration during thermal transitions simulates transportation and operational dynamics. These combined environmental tests reveal synergistic failure modes invisible to single-parameter testing. Modern temperature cycling test chambers integrate humidity control and vibration systems for comprehensive validation.

Test Parameter | Standard Level | Accelerated Level | Purpose |

Temperature Range | -40°C to +85°C | -55°C to +150°C | Validate design margins |

Ramp Rate | 5°C/min | 15°C/min | Induce thermal shock |

Dwell Time | 30 minutes | 15 minutes | Maximize cycle count |

Relative Humidity | 50% RH | 85% RH | Accelerate corrosion |

Analyzing Material Degradation After Thermal Cycling

Visual Inspection Techniques and Surface Analysis

Post-cycling examination begins with visual inspection under magnification. Stereomicroscopes (20-50x) reveal solder joint cracking, wire bond lifting, and package warpage. Dye penetrant testing highlights surface-breaking cracks invisible to naked eyes. Optical profilometry quantifies component deformation and coplanarity changes. Advanced techniques like scanning acoustic microscopy (SAM) detect internal delamination without destructive sectioning.

Cross-Sectional Metallography and Failure Analysis

Destructive analysis through precision sectioning exposes internal failure progression. Epoxy mounting preserves delicate structures during grinding and polishing. Metallographic etching reveals grain structure changes, intermetallic growth, and crack paths. Scanning electron microscopy (SEM) provides high-resolution imaging of fracture surfaces. Energy-dispersive X-ray spectroscopy (EDX) identifies elemental migration and contamination. These techniques definitively establish root cause mechanisms.

Electrical Performance Monitoring During Test Cycles

Continuous electrical monitoring detects incipient failures before complete functional loss. Resistance measurements on daisy-chain structures quantify progressive degradation. Capacitance changes indicate delamination. Leakage current increases signal insulation breakdown. Data acquisition systems integrated with the temperature cycling chamber record electrical parameters throughout testing, correlating failures with specific cycle numbers and temperature conditions.

Using Test Data to Improve Component Reliability

Statistical Analysis for Predicting Field Failure Rates

Weibull analysis of cycling test data extrapolates laboratory results to field lifetime predictions. The shape parameter (β) indicates whether failures result from random defects (β<1), useful life (β≈1), or wear-out mechanisms (β>1). The characteristic life (η) provides mean time to failure estimates. Confidence intervals account for sample size limitations. These statistical tools transform raw test data into actionable reliability metrics.

Design Modifications Based on Failure Mode Insights

Identified failure mechanisms guide targeted design improvements. Solder joint failures prompt component repositioning to minimize CTE mismatches or underfill addition for stress distribution. Delamination issues drive adhesive reformulation or surface preparation changes. Wire bond failures lead to alternative interconnect technologies like copper pillars. Each iteration undergoes validation cycling to verify improvements before production release.

Supplier Qualification and Quality Control Applications

Temperature cycling tests establish supplier acceptance criteria and incoming quality standards. Component manufacturers undergo qualification testing demonstrating adequate thermal fatigue resistance. Production lots receive sample testing verifying process control. Failure rate trends indicate process drift requiring corrective action. The temperature cycling chamber becomes a gatekeeper ensuring only robust components enter critical applications.

Reliability Metric | Calculation Method | Target Value |

Mean Cycles to Failure (MCTF) | Weibull characteristic life | >2000 cycles |

First Failure Point | Minimum observed failure | >500 cycles |

Failure Rate at 1000 Cycles | Cumulative distribution function | <5% |

Expose Hidden Weaknesses Early with LIB Industry Temperature Cycling Chambers

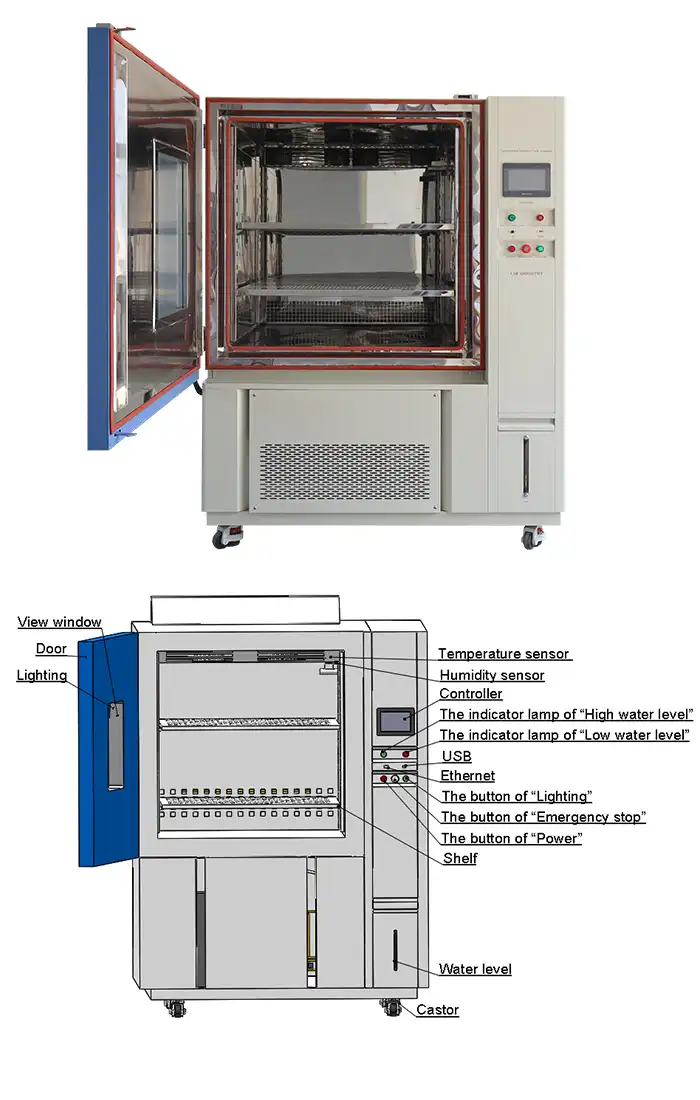

| Name | Temperature Cycling Chamber | |||||

Model | TH-100 | |||||

Temperature range | -20℃ ~+150 ℃ | |||||

Low type | A: -40℃ B:-70℃ C -86℃ | |||||

Humidity Range | 20%-98%RH | |||||

Temperature deviation | ± 2.0 ℃ | |||||

Heating rate | 3 ℃ / min | |||||

Cooling rate | 1 ℃ / min | |||||

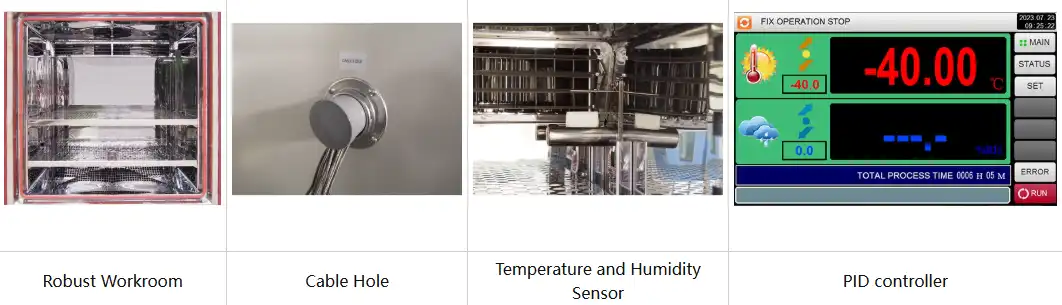

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | |||||

Exterior material | Steel Plate with protective coating | |||||

Interior material | SUS304 stainless steel | |||||

Standard configuration | 1 Cable hole (Φ 50) with plug; 2 shelves | |||||

Timing Function | 0.1~999.9 (S,M,H) settable | |||||

Precision Control Systems for Repeatable Results

LIB Industry temperature cycling chambers utilize PT100 Class A sensors delivering 0.001°C resolution, ensuring temperature accuracy within ±0.5°C throughout the test volume. PID controllers with adaptive algorithms maintain stable conditions even during rapid transitions. Programmable profiles store up to 100 preset cycles with automatic execution. Ethernet connectivity enables remote monitoring and data download, supporting laboratory information management systems (LIMS) integration for complete traceability.

Versatile Chamber Configurations for Diverse Testing Needs

Chamber volumes from 100L to 1000L accommodate products ranging from individual components to complete assemblies. Temperature ranges extend from -70°C to +150°C, covering virtually all industrial applications. Adjustable ramp rates (5-15°C/min) allow both gradual environmental simulation and aggressive thermal shock testing. SUS304 stainless steel interiors resist corrosion during humidity-combined testing. Observation windows with interior lighting enable in-situ monitoring without interrupting test sequences.

Safety Features and Regulatory Compliance for Critical Applications

Comprehensive protection systems include independent hardware temperature limiters, refrigerant high-pressure cutoffs, and electrical leakage protection. Optional explosion-proof configurations with smoke detection and fire suppression suit battery testing applications. Pressure relief valves automatically compensate for rapid temperature-induced pressure changes. CE certification and ISO 9001 quality management ensure international regulatory compliance. Three-year warranties with lifetime support demonstrate manufacturing confidence.

Conclusion

Temperature cycling tests systematically expose thermal fatigue vulnerabilities through controlled environmental stress application. By precisely manipulating temperature extremes, transition rates, and cycle counts, engineers accelerate years of field exposure into manageable test durations. The resulting failure data - analyzed through visual inspection, destructive analysis, and electrical monitoring - reveals design weaknesses requiring correction. Statistical interpretation predicts field reliability, guiding design refinements and supplier qualification decisions.

FAQs

How many thermal cycles are needed to validate product reliability?

Cycle requirements depend on application severity and expected service life. Consumer electronics typically require 500-1000 cycles, automotive components demand 1000-3000 cycles, while aerospace applications may specify 2000+ cycles. Accelerated profiles with extended temperature ranges reduce required cycle counts.

Can temperature cycling tests damage products that would otherwise pass field use?

Properly designed test profiles matching actual environmental exposure should not induce unrealistic failures. Excessively rapid ramp rates or extreme temperatures beyond operational limits may create failure modes absent in normal service. Profile validation against field data ensures test relevance.

What's the difference between temperature cycling and thermal shock testing?

Temperature cycling employs controlled ramp rates (typically 5-15°C/min) with dwell periods simulating gradual environmental changes. Thermal shock testing uses immediate exposure to temperature extremes (transfer between chambers) inducing maximum thermal gradient stress. Applications determine appropriate methodology.

Partner with LIB Industry, a leading temperature cycling chamber manufacturer, to strengthen your product validation processes. Our precision-engineered test equipment delivers the controlled environmental conditions necessary for comprehensive thermal fatigue assessment. Contact our technical specialists at ellen@lib-industry.com to discuss custom chamber configurations and application-specific testing protocols tailored to your reliability requirements