How a Dust Proof Test Chamber Meets Defense Dust Resistance Standards?

Defense applications demand equipment that performs reliably in the harshest conditions, including extreme dust exposure. A dust proof test chamber validates whether military hardware can withstand sand-laden environments without degradation. These specialized chambers replicate battlefield conditions - from Middle Eastern deserts to Arctic tundra dust storms - by controlling particle concentration, temperature, and exposure duration. Through rigorous testing aligned with international protocols like MIL-STD-810G and IEC 60529, manufacturers ensure their equipment won't fail when soldiers depend on it most. This controlled environment reveals vulnerabilities in seals, bearings, and electronic housings before deployment, saving lives and mission success.

What Are Defense Dust Resistance Requirements?Military Standards Governing Dust Protection

Defense organizations worldwide enforce stringent regulations to guarantee equipment survivability. MIL-STD-810G Method 510 establishes precise testing parameters for airborne particulates, specifying dust composition, concentration levels, and test durations. NATO STANAG 4370 provides additional guidelines for vehicles and portable systems operating in coalition environments. These frameworks ensure interoperability across allied forces while maintaining minimum performance thresholds.

parameters for airborne particulates, specifying dust composition, concentration levels, and test durations. NATO STANAG 4370 provides additional guidelines for vehicles and portable systems operating in coalition environments. These frameworks ensure interoperability across allied forces while maintaining minimum performance thresholds.

Ingress Protection Ratings for Combat Systems

The IP (Ingress Protection) rating system classifies equipment based on dust penetration resistance. Military applications typically require IP6X certification, indicating complete protection against dust ingress during eight-hour exposures at specified concentrations. Communication devices, optical instruments, and weapons systems must maintain operational integrity even when microscopic particles attempt infiltration through ventilation ports or mechanical interfaces.

Environmental Severity Categories

Defense standards categorize operational environments into severity levels ranging from moderate continental climates to extreme desert theaters. Category A1 represents basic protection for temperate zones, while A3 addresses severe conditions with sustained high-temperature dust storms. Each category dictates specific test parameters - particle size distribution, velocity, and concentration - that equipment must endure without functional compromise.

Key Testing Methods for Military EquipmentBlowing Dust Test Protocols

This methodology simulates natural wind-driven dust environments by circulating fine particles at controlled velocities. Test specimens undergo exposure periods ranging from six to twelve hours while equipment operates under normal power conditions. Engineers monitor critical parameters: motor torque, optical clarity, and seal integrity. The chamber maintains particle concentrations between 2-4 kg/m³, matching conditions observed during sustained desert operations.

Blowing Sand Evaluation Procedures

Coarser sand particles require different testing approaches due to their abrasive characteristics. Blowing sand tests employ particles ranging from 150-850 micrometers, propelled at velocities mimicking desert windstorms. This aggressive protocol identifies weaknesses in protective coatings, reveals bearing vulnerabilities, and exposes inadequate sealing mechanisms. Test durations typically span ninety minutes, representing acute exposure scenarios during tactical movements.

Settling Dust Assessment Techniques

Gravitational dust settlement poses unique challenges for horizontal surfaces and ventilation systems. This test variant introduces suspended particles that gradually descend onto equipment surfaces over extended periods. The methodology evaluates whether accumulation causes overheating, blocks cooling pathways, or degrades sensor performance. Military radars, antenna arrays, and solar panels undergo this evaluation to verify long-term functionality in dusty deployments.

Simulating Desert and Extreme Dust ConditionsTemperature-Controlled Dust Exposure

Desert environments combine intense heat with airborne particulates, creating compound stress conditions. Advanced dust proof test chambers integrate heating elements capable of reaching 50°C while simultaneously maintaining target dust concentrations. This dual-stress approach reveals thermal expansion effects on seals, identifies lubrication failures accelerated by particle contamination, and tests electronic components subjected to simultaneous heat and dust infiltration.

Variable Humidity and Dust Interaction

Humidity fluctuations dramatically alter dust behavior and adhesion characteristics. Chambers equipped with humidity control simulate morning dew condensation on dust-coated surfaces, creating abrasive slurries that accelerate corrosion. Military vehicles operating in coastal desert regions face this specific threat, where salt-laden moisture combines with silica dust to attack protective finishes and electrical connections.

Pressure Differential Testing for Sealed Enclosures

Vacuum systems integrated into modern chambers replicate altitude changes and pressurized enclosures. By creating negative pressure differentials, engineers verify whether protective seals maintain integrity when external atmospheric pressure drops. Aviation equipment, high-altitude communication systems, and specialized optics undergo this evaluation to prevent dust infiltration during rapid altitude transitions.

|

|

| Name | dust proof test chamber |

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3 mm |

Internal Diameter of IPX6 Nozzle | 12.5 mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

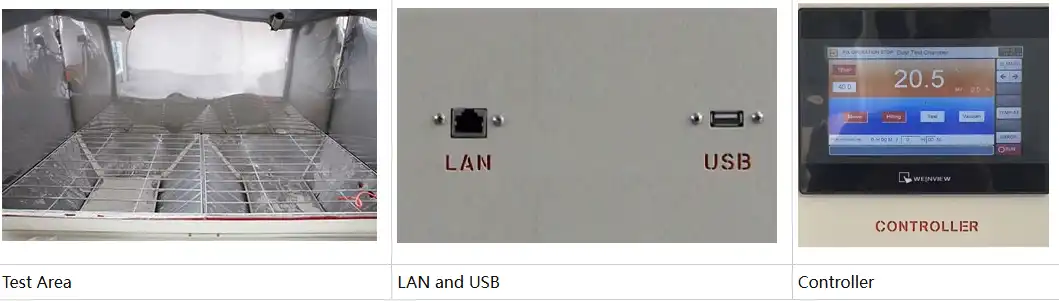

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

Evaluating Equipment Reliability under Harsh EnvironmentsFunctional Performance During Exposure

Rather than simple pass-fail assessments, defense testing demands continuous operational monitoring throughout exposure cycles. Weapons must cycle reliably, radios maintain signal clarity, and vehicles deliver full power output while dust circulates. Real-time data acquisition systems track performance degradation, establishing objective metrics for comparison against baseline capabilities measured in clean-room conditions.

maintain signal clarity, and vehicles deliver full power output while dust circulates. Real-time data acquisition systems track performance degradation, establishing objective metrics for comparison against baseline capabilities measured in clean-room conditions.

Post-Test Inspection and Disassembly Analysis

Visual inspection alone cannot reveal microscopic particle infiltration into critical assemblies. Complete disassembly following test completion exposes internal contamination levels, bearing wear patterns, and seal deformation. Metallurgical analysis identifies abrasion depth on precision surfaces, while filter media examination quantifies particle capture efficiency. This forensic approach guides design modifications before production commitment.

Accelerated Life Cycle Predictions

By correlating dust exposure intensity with observed degradation rates, engineers extrapolate operational longevity estimates. A twelve-hour chamber test might represent six months of field deployment based on established conversion factors. These predictions inform maintenance scheduling, parts replacement intervals, and warranty structures for defense procurement contracts.

Data Logging and Performance Metrics for ComplianceAutomated Environmental Parameter Recording

Modern programmable controllers continuously document dust proof test chamber conditions at one-minute intervals throughout test sequences. Temperature fluctuations, humidity drift, dust concentration variations, and air velocity measurements create comprehensive environmental profiles. This documentation satisfies audit requirements for certification bodies while providing manufacturers with detailed test condition records for quality management systems.

Parameter | Measurement Range | Logging Frequency | Compliance Standard |

Temperature | Ambient to 50°C | Every 60 seconds | MIL-STD-810G |

Dust Concentration | 2-4 kg/m³ | Every 120 seconds | IEC 60529 |

Test Duration | 0-99 hours 59 minutes | Continuous | ISO 20653 |

Equipment Performance Data Acquisition

Embedded sensors within test specimens transmit operational data to external recording systems via dust-proof connectors. Battery voltage, current draw, output power, and signal quality metrics stream throughout exposure periods. This parallel data collection enables correlation between environmental stress and functional degradation, identifying precise failure thresholds for specific subsystems.

Compliance Verification Reporting

Certification authorities require standardized reporting formats demonstrating adherence to specified test protocols. Reports include pre-test calibration certificates, environmental parameter graphs, equipment performance curves, and post-test inspection photographs. Third-party witnesses often observe critical military tests, adding authentication layers that governmental procurement agencies demand before contract awards.

Report Section | Required Content | Verification Method |

Test Setup | Chamber calibration certificates, specimen configuration | Photographic documentation |

Environmental Data | Temperature, humidity, concentration graphs | Automated data logs |

Performance Results | Operational metrics during exposure | Real-time sensor data |

Benefits of Dust Proof Chambers in Defense ApplicationsRisk Mitigation Through Pre-Deployment Validation

Discovering equipment vulnerabilities during laboratory testing prevents catastrophic field failures that endanger personnel. A communication system that fails during a dust storm could compromise mission coordination and troop safety. Chamber testing identifies these weaknesses during development phases when corrective actions remain cost-effective, avoiding expensive retrofits to deployed systems.

Cost Reduction via Design Optimization

Iterative testing enables engineers to compare sealing strategies, filter technologies, and protective coating effectiveness without deploying multiple prototypes to actual desert environments. A single chamber test cycle costing thousands of dollars replaces field evaluations requiring hundreds of thousands in logistics, personnel deployment, and time delays. This accelerated development process shortens procurement timelines significantly.

Standardization Across Defense Platforms

Utilizing consistent test methodologies ensures comparable protection levels across diverse equipment categories. Tank optics, infantry radios, and drone guidance systems tested under identical protocols provide commanders with predictable reliability profiles. This standardization simplifies logistics planning and enables confident equipment substitution during dynamic operational requirements.

Engineered for Defense Rigor: The LIB Industry Dust Proof Test ChamberAdvanced Chamber Design Features

The LIB Industry dust proof test chambers incorporates 304 stainless steel construction that resists corrosion from abrasive dust particles during thousands of test cycles. Large observation windows with integrated dust scrapers allow continuous visual monitoring without interrupting test sequences. Electromagnetic door locks maintain seal integrity during violent dust circulation, preventing leakage that would compromise test validity.

Precision Control Systems

Programmable LCD touchscreen controllers offer intuitive operation while storing up to fifty test protocols in internal memory. Ethernet connectivity enables remote monitoring and data export to laboratory information management systems. Temperature control accuracy within ±2°C ensures reproducible test conditions, while integrated pressure regulators maintain precise vacuum levels for altitude simulation scenarios.

Chamber Model | Internal Volume | Temperature Range | Vacuum System | Noise Level |

DI-800 | 800 liters | Ambient to 50°C | Equipped with pressure gauge and filter | ≤65 dBA |

DI-1000 | 1000 liters | Ambient to 50°C | Equipped with pressure gauge and filter | ≤65 dBA |

Compliance Certification and Validation

Chambers manufactured by LIB Industry meet international standards including IEC 60529 and ISO 20653, ensuring test results gain acceptance by defense procurement authorities globally. Regular calibration services maintain measurement accuracy traceable to national standards laboratories. This certification infrastructure supports manufacturers pursuing contracts with NATO members, Asian defense forces, and Middle Eastern militaries.

Conclusion

Validating defense equipment against dust ingress requires specialized chambers that accurately replicate battlefield conditions while providing precise environmental control. Through compliance with military standards, comprehensive data logging, and rigorous test methodologies, manufacturers demonstrate equipment readiness for deployment in harsh environments. The investment in quality dust proof test chambers translates directly into soldier safety, mission success, and long-term cost savings across defense procurement programs.

FAQsWhat dust particle sizes do defense standards require for testing?

Military specifications typically mandate testing with particles ranging from 50-850 micrometers depending on the test method. Blowing dust tests use finer particles (50-150 micrometers), while blowing sand protocols employ coarser grades (150-850 micrometers) to simulate different environmental threats.

How long do typical defense dust resistance tests last?

Standard test durations vary from ninety minutes for acute blowing sand exposure to twelve hours for sustained blowing dust scenarios. Some specialized protocols extend to ninety-nine hours for equipment intended for prolonged desert deployments without maintenance opportunities.

Can dust proof chambers test multiple equipment pieces simultaneously?

Chamber capacity determines specimen quantity, with larger 1000-liter models accommodating multiple small devices or single large assemblies. However, each specimen requires adequate airflow circulation and must not create particle shadowing effects that compromise test validity for adjacent equipment.

Contact LIB Industry, your trusted dust proof test chamber manufacturer and supplier, for custom testing solutions tailored to defense applications. Our factory delivers CE-approved chambers backed by comprehensive technical support. Reach us at ellen@lib-industry.com to discuss your specific requirements.