How a UV Resistance Test Chamber Evaluates Textile Dye Stability?

Imagine your vibrant textile quietly fading under the sun—outdoor furniture losing its brilliance, sportswear losing its vivid colors, or upholstery showing uneven discoloration long before it ever reaches the consumer. A UV resistance test chamber makes this invisible damage visible, simulating prolonged sunlight exposure in a controlled environment. By accelerating months or even years of outdoor degradation into days, these chambers reveal how dyes and fibers respond to ultraviolet radiation, moisture, and temperature cycles, helping manufacturers ensure long-term color stability, structural integrity, and consumer satisfaction.

A UV resistance test chamber evaluates textile dye stability by exposing fabric samples to controlled ultraviolet radiation that mimics prolonged sunlight exposure. The chamber measures color degradation through spectrophotometric analysis, monitoring changes in lightfastness ratings over accelerated testing periods. By simulating months or years of outdoor exposure in days, these chambers help manufacturers predict how textile dyes will perform in real-world conditions. The evaluation involves tracking both visual color changes and molecular-level degradation patterns, providing quantifiable data on fade resistance, color shift, and overall durability of dyed textiles under UV stress.

Why UV Stability Matters for Textile Dyes?Economic Impact of Color Fading

Color fading represents a substantial financial burden for textile manufacturers and retailers. When dyes deteriorate prematurely, products lose market value and consumer trust diminishes. Studies indicate that color inconsistency accounts for approximately 60% of textile returns in the retail sector, translating to millions in lost revenue annually for global brands.

prematurely, products lose market value and consumer trust diminishes. Studies indicate that color inconsistency accounts for approximately 60% of textile returns in the retail sector, translating to millions in lost revenue annually for global brands.

Consumer Expectations and Brand Reputation

Modern consumers demand textiles that maintain their vibrant appearance throughout the product lifecycle. A sofa that fades within two years or outdoor apparel that loses its intensity after minimal sun exposure damages brand credibility irreparably. Manufacturers must validate dye stability before market release to protect their reputation.

Regulatory Compliance Requirements

International standards such as ISO 105-B02 and AATCC Test Method 16 mandate specific lightfastness ratings for various textile applications. Outdoor furniture fabrics typically require a minimum rating of 5-6 on the Blue Wool Scale, while interior textiles may need ratings of 3-4. Non-compliance can result in market access restrictions.

Effects of Sunlight on Color FastnessPhotodegradation Mechanisms in Dye Molecules

Ultraviolet radiation triggers photochemical reactions that break chromophoric bonds within dye molecules. The energy

from UV wavelengths - particularly in the 290-400nm range - causes electron excitation, leading to molecular fragmentation. Azo dyes, commonly used in textiles, are especially vulnerable to cleavage at the nitrogen-nitrogen double bond.

Wavelength-Specific Damage Patterns

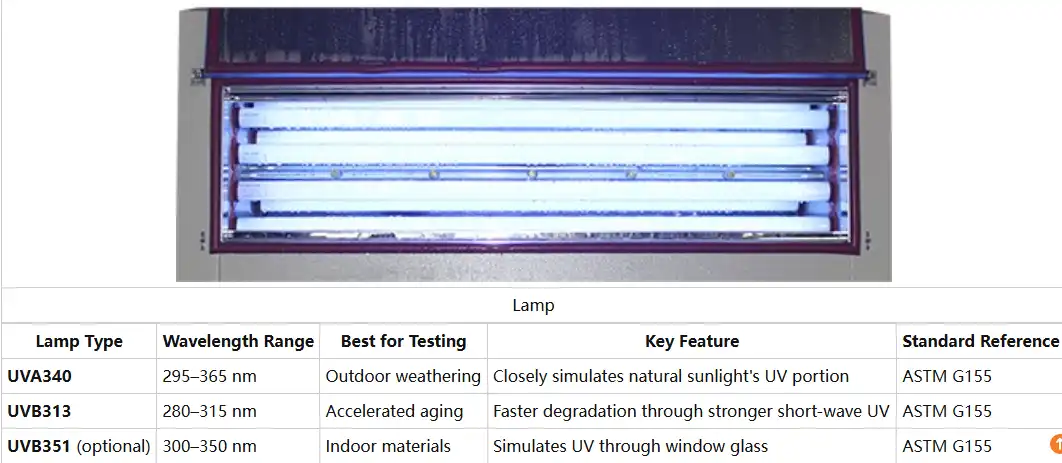

Different UV wavelengths produce distinct degradation patterns. UVB radiation (313nm) causes rapid surface-level damage, creating immediate visible fading. UVA radiation (340nm) penetrates deeper into fiber structures, causing gradual but comprehensive deterioration. Understanding these patterns helps manufacturers select appropriate dye chemistries for specific applications.

Synergistic Environmental Factors

UV exposure rarely occurs in isolation. Moisture, temperature fluctuations, and atmospheric pollutants amplify degradation rates exponentially. A dye that maintains stability under dry UV exposure may fail rapidly when combined with humidity cycles above 95% RH. This synergy explains why laboratory testing must replicate multi-factor environmental conditions.

Accelerated UV Testing for Fabrics and FibersCondensation and Spray Cycle Simulation

Advanced UV resistance test chambers alternate between UV irradiation and moisture exposure to replicate morning dew and rain events. The water spray cycle, adjustable from 1 to 9999 hours and 59 minutes, deposits controlled moisture quantities - typically 0.8-1.0mm per 80cm² per hour - onto heated specimens. This thermal shock accelerates degradation mechanisms that would take months outdoors.

Irradiance Intensity Calibration

Precise irradiance control between 0.3-20 W/m² enables testing across various climatic conditions. Equatorial regions experience approximately 10-15 W/m² UV intensity, while temperate zones average 5-8 W/m². By adjusting intensity levels, technicians simulate specific geographic locations, providing region-specific performance predictions.

Temperature Profile Management

The chamber maintains specimen temperatures from ambient to 90°C (±2℃), with black panel temperatures reaching 35-80°C. These elevated temperatures accelerate thermally-activated degradation pathways. The 50mm distance between specimens and eight 40W fluorescent UV lamps ensures uniform heating and exposure across all 56 test positions.

Testing Parameter | Standard Outdoor Exposure | Accelerated Chamber Testing |

UV Intensity | 5-15 W/m² | 0.3-20 W/m² (adjustable) |

Temperature Range | 10-40°C (seasonal) | Ambient-90°C (controlled) |

Moisture Cycles | Irregular rain/dew | Programmable 1-9999H59M |

Testing Duration | 6-24 months | 200-1000 hours |

Monitoring Physical and Chemical Changes in TextilesSpectrophotometric Color Measurement

Quantitative color assessment employs spectrophotometers that measure reflectance across the visible spectrum. The CIELAB color space provides numerical values for lightness (L), red-green axis (a), and blue-yellow axis (b). Total color difference (ΔE) calculations reveal degradation severity, with ΔE values above 2.0 indicating perceptible color change.

Tensile Strength Degradation Analysis

UV radiation doesn't merely affect color - it compromises fiber integrity. Polymer chain scission reduces tensile strength by 10-40% in severely degraded samples. Testing protocols measure breaking force before and after UV exposure, revealing whether fabric will maintain structural performance throughout its intended lifespan.

Surface Morphology Examination

Scanning electron microscopy reveals micro-level surface changes invisible to naked eyes. UV-exposed fibers often exhibit surface crazing, fiber splitting, and crystalline structure disruption. These physical transformations correlate with chemical degradation, providing comprehensive material performance insights.

Textile Property | Measurement Method | Acceptable Change Threshold |

Color Difference (ΔE) | Spectrophotometry | <2.0 for critical applications |

Tensile Strength | Force elongation testing | <15% reduction |

Surface Roughness | Profilometry | <25% increase |

Predicting Long-term Color RetentionCorrelation Between Lab and Field Results

Establishing accurate correlation factors requires parallel testing of control samples under both laboratory and outdoor conditions. Research indicates that 500 hours of properly calibrated UV resistance test chamber testing approximates 12-18 months of outdoor exposure in temperate climates. This ratio varies based on geographic location, season, and material composition.

Statistical Modeling of Fade Rates

Advanced prediction models employ exponential decay functions to forecast long-term performance. By plotting color difference values against exposure time, researchers identify inflection points where degradation accelerates. These mathematical models enable manufacturers to guarantee specific performance periods with statistical confidence.

Material-Specific Performance Curves

Different fiber types and dye classes exhibit unique degradation curves. Natural fibers like cotton often show linear fade progression, while synthetic polyesters may demonstrate initial stability followed by rapid deterioration. Creating material-specific performance databases allows accurate prediction across diverse product categories.

Standard Methods for Textile UV Resistance TestingISO 105-B02 Xenon Arc Exposure

This international standard specifies exposure conditions using xenon arc lamps that closely replicate the full solar spectrum. Testing continues until control fabrics reach specified Blue Wool Scale ratings, providing comparative lightfastness grades from 1 (poor) to 8 (excellent). The method requires controlled black standard temperature of 65°C and specified humidity levels.

AATCC Test Method 16 Options

The American Association of Textile Chemists and Colorists offers multiple testing options. Option 1 employs xenon arc lamps, while Option 3 utilizes fluorescent UV lamps similar to those in the UV-SI-260 chamber. Option 3 provides accelerated results particularly valuable for quality control applications where rapid feedback drives production decisions.

Blue Wool Scale Reference Standards

This standardized fading scale uses eight graded wool fabric references with known lightfastness ratings. Test samples are exposed alongside these standards, and testing concludes when the appropriate reference standard achieves Grade 4 on the Grey Scale for color change. This comparative method eliminates equipment calibration variables.

Test Standard | Light Source | Application Focus | Typical Duration |

ISO 105-B02 | Xenon arc | General textiles | 24-120 hours |

AATCC 16.3 | Fluorescent UV | Accelerated screening | 40-200 hours |

AATCC 186 | Xenon arc | Outdoor textiles | 100-500 hours |

Understanding LIB Industry's UV Resistance Test ChamberAdvanced Temperature Control System

The LIB Industry UV resistance test chamber features dual-temperature monitoring through ambient chamber temperature (up to 90°C ±2℃) and black panel temperature (35-80°C). This dual-sensor approach ensures specimens experience realistic surface heating while the overall chamber maintains programmed conditions. The programmable color LCD touchscreen controller enables complex multi-stage temperature profiles.

Precision Water Spray System

Ten strategically positioned nozzles with 0.5mm diameter deliver controlled moisture deposition. The automatic water supply connects to an integrated purification system, eliminating mineral deposits that could create non-uniform wetting patterns. This attention to water quality prevents false results from contamination-induced degradation.

Flexible Sample Configuration

The chamber accommodates 56 specimens measuring 75×150mm, utilizing both flat and three-dimensional holders. Removable sample shelves facilitate rapid specimen exchange, minimizing downtime between test batches. The 450×1170×500mm internal dimensions provide sufficient space for diverse sample geometries without compromising exposure uniformity.

minimizing downtime between test batches. The 450×1170×500mm internal dimensions provide sufficient space for diverse sample geometries without compromising exposure uniformity.

Safety and Monitoring Features

Comprehensive protection systems include over-temperature shutdown, over-current protection, water shortage detection, earth leakage safeguards, and phase sequence monitoring. Ethernet connectivity enables remote monitoring and data logging, supporting compliance documentation requirements and facilitating multi-site testing coordination.

Conclusion

UV resistance test chambers provide invaluable data for predicting textile dye stability under sunlight exposure. Through controlled simulation of ultraviolet radiation, moisture, and temperature cycles, these chambers accelerate natural aging processes, delivering results in days rather than months. Quantitative measurements of color change, structural integrity, and surface characteristics enable manufacturers to validate product performance before market launch. Adherence to international testing standards ensures consistency and regulatory compliance across global markets.

FAQs

How long should textile samples be tested in a UV resistance chamber?

Testing duration depends on intended application and required lightfastness rating. Interior textiles typically require 100-300 hours, while outdoor fabrics may need 500-1000 hours. Manufacturers should consult relevant industry standards and conduct correlation studies to establish appropriate testing protocols for their specific products.

Can UV resistance testing predict real-world performance accurately?

When properly calibrated with field exposure data, chamber testing provides reliable predictions. Correlation factors typically range from 1:15 to 1:30, meaning one week of chamber testing approximates several months outdoors. Accuracy improves when testing incorporates moisture cycles and temperature variations that replicate actual usage conditions.

What lightfastness rating should different textile products achieve?

Automotive interiors require ratings of 4-5, outdoor furniture needs 5-7, and window treatments should achieve 4-6 on standard scales. Products with higher UV exposure demands or longer expected lifespans necessitate superior ratings. Regulatory requirements and brand positioning also influence minimum acceptable performance thresholds.

Ready to validate your textile products' UV resistance? LIB Industry, a leading UV resistance test chamber manufacturer and supplier, offers comprehensive testing solutions tailored to your quality assurance needs. Our UV-SI-260 chamber delivers precise, reliable results that protect your brand reputation. Contact our technical specialists at ellen@lib-industry.com to discuss your specific testing requirements.