In the highly competitive beverage industry, consistent product quality is crucial. Shelf life test chambers provide precise temperature and humidity control to simulate real-world storage conditions, from hot warehouses to refrigerated distribution networks. These controlled environments allow manufacturers to predict flavor stability, carbonation retention, microbial growth, and packaging performance, ensuring every bottle, can, or carton meets consumer expectations throughout its intended lifespan.

“Our LIB temperature-humidity chamber has been working perfectly,” reports a satisfied client from Russia specializing in instrumentation. “Everything is good, and the chamber performs exactly as expected.” This feedback highlights the reliability and effectiveness of LIB's chambers in supporting beverage quality assurance across diverse global applications.

A shelf life test chamber serves as an indispensable tool for beverage manufacturers seeking to validate product stability across varying storage conditions. These precision-controlled environments simulate real-world scenarios - from scorching warehouse summers to refrigerated distribution networks - allowing producers to predict how their formulations will perform throughout their intended lifespan. By replicating temperature swings, humidity variations, and extended timeframes in compressed testing periods, manufacturers gain critical insights into flavor degradation, carbonation loss, separation issues, and microbial growth patterns. This proactive approach transforms quality assurance from reactive problem-solving into strategic product development, ensuring every bottle, can, or carton delivers the intended sensory experience from production line to final consumption.

Why Beverage Stability Testing Matters?

Consumer Expectations Drive Quality Standards

Modern consumers demand consistency in every purchase. A coffee drink should taste identical whether purchased today or three months from now. This expectation places enormous pressure on manufacturers to guarantee stability throughout distribution cycles that may span multiple climate zones and storage conditions. Shelf life testing chambers provide the empirical data needed to make confident expiration date claims while minimizing customer complaints and brand damage.

from now. This expectation places enormous pressure on manufacturers to guarantee stability throughout distribution cycles that may span multiple climate zones and storage conditions. Shelf life testing chambers provide the empirical data needed to make confident expiration date claims while minimizing customer complaints and brand damage.

Regulatory Compliance Requirements

Food safety authorities worldwide mandate substantiated shelf life declarations on beverage labels. Without documented evidence from controlled testing, manufacturers risk regulatory penalties, product recalls, and market withdrawal. Testing chambers generate the traceable, scientifically valid data that regulatory bodies require during audits and inspections.

Economic Impact of Product Failures

Premature spoilage translates directly into financial losses through waste, recalls, and damaged retailer relationships. Conversely, overly conservative shelf life declarations reduce market competitiveness and distribution flexibility. Precise testing identifies the optimal balance, maximizing profitability while maintaining safety margins.

Temperature and Humidity Effects on Flavor and Aroma

Chemical Reaction Kinetics Under Variable Conditions

Temperature fluctuations accelerate oxidation, Maillard reactions, and enzymatic activity that alter beverage chemistry. Fruit juices may develop off-flavors as vitamin C degrades; dairy-based drinks can undergo protein denaturation; carbonated beverages lose dissolved CO₂. The LIB shelf life test chamber's temperature range of -86°C to +150°C enables comprehensive evaluation across frozen storage, refrigeration, ambient conditions, and even tropical heat exposure scenarios.

Moisture Transfer and Packaging Integrity

Humidity levels dramatically affect packaging performance. High moisture environments can weaken cardboard cartons, promote label degradation, or cause condensation that damages product aesthetics. The shelf life test chamber's 20%-98% RH range allows testing of barrier properties under extreme conditions, revealing potential packaging failures before they occur in distribution.

Volatile Compound Preservation

Aromatic compounds that define beverage character are particularly vulnerable to environmental stress. Coffee beverages lose characteristic notes; tea drinks develop stale profiles; flavored waters lose their essence. Controlled humidity testing identifies optimal packaging materials and storage conditions that preserve these delicate volatile profiles throughout the product's marketable life.

Environmental Parameter | Impact on Beverage Quality | Testing Range |

Temperature Extremes | Accelerates chemical degradation, affects viscosity | -86°C to +150°C |

Humidity Variation | Influences packaging integrity, label adhesion | 20% - 98% RH |

Temperature Cycling | Simulates transportation stress, reveals weakness | Programmable cycles |

Packaging Material Considerations for Beverages

Barrier Property Validation

Different beverage types require specific barrier characteristics. Oxygen-sensitive juices need high O₂ barriers; carbonated drinks demand CO₂ retention; shelf-stable dairy alternatives require multi-layer protection. Testing chambers evaluate how various packaging materials - PET, glass, aluminum, multilayer composites - perform under stress conditions that compress months of real-world exposure into weeks of accelerated testing.

CO₂ retention; shelf-stable dairy alternatives require multi-layer protection. Testing chambers evaluate how various packaging materials - PET, glass, aluminum, multilayer composites - perform under stress conditions that compress months of real-world exposure into weeks of accelerated testing.

Material-Product Interaction Studies

Chemical migration from packaging into beverages poses both safety and quality concerns. Plasticizers, adhesives, and coating materials may leach into products over time, particularly under elevated temperatures. The chamber's precise temperature control allows systematic investigation of migration kinetics, ensuring compliance with food contact regulations.

Structural Integrity Assessment

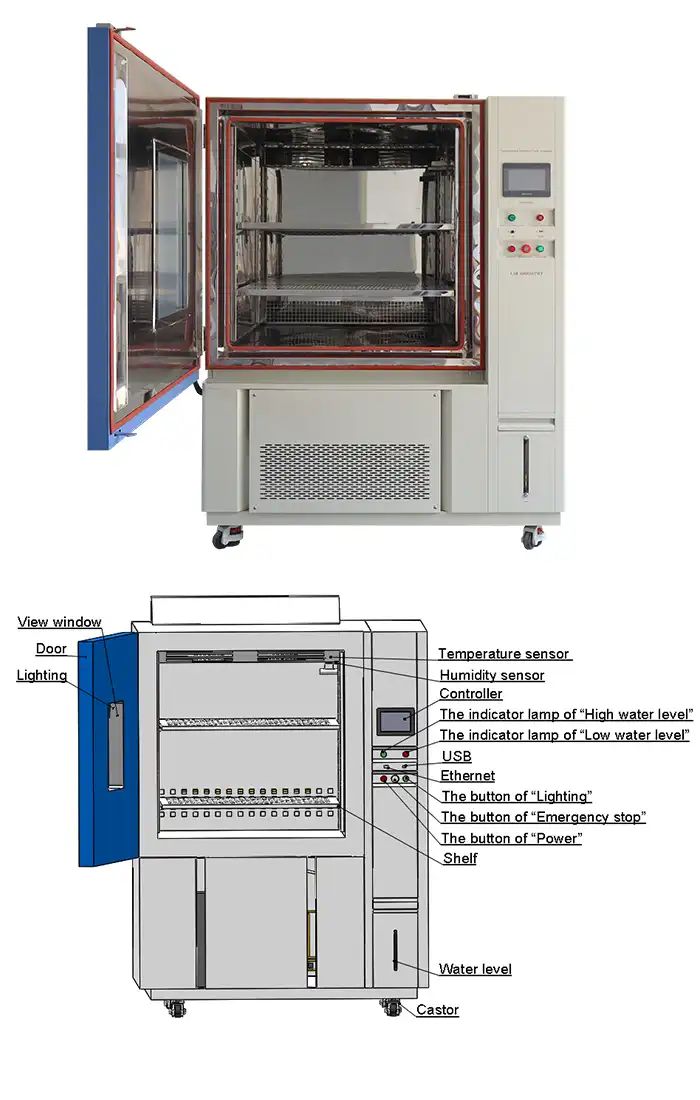

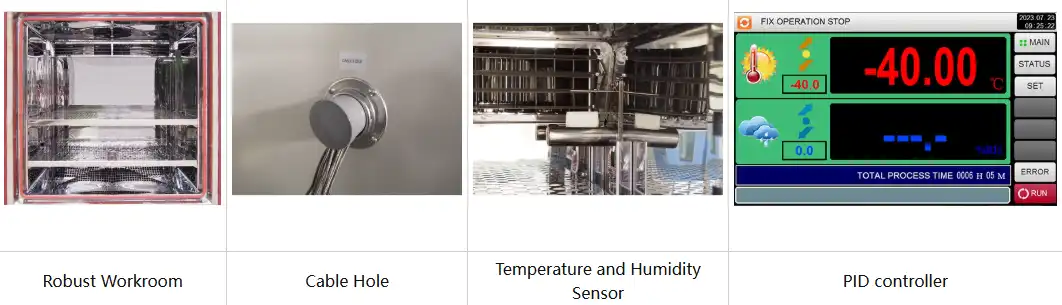

Physical packaging failures - seal weakness, delamination, puncture vulnerability - often manifest only after prolonged exposure to environmental stress. The mirror-surface #304 stainless steel interior of the TH-225 and TH-500 models facilitates visual inspection throughout testing cycles, while the perforated shelf design accommodates various package formats without compromising airflow uniformity.

Accelerated Aging Techniques for Beverage Products

Arrhenius Equation Applications

The fundamental principle behind accelerated testing relies on reaction rate dependencies on temperature. By elevating storage temperatures above ambient conditions, manufacturers compress months or years of shelf life into manageable testing windows. The chamber's 3°C/min heating rate and ±0.5°C temperature fluctuation ensure precise control needed for valid extrapolations to real-world conditions.

Q10 Factor Methodology

This widely adopted approach assumes reaction rates double with every 10°C temperature increase. By testing at strategically selected elevated temperatures - while remaining below degradation thresholds that would invalidate the model - beverage scientists generate predictive curves that forecast stability across entire distribution networks spanning diverse climates.

Challenge Testing Protocols

Beyond simple temperature elevation, sophisticated protocols incorporate cycling conditions that mimic transportation vibration, day-night temperature swings, and seasonal variations. The programmable touchscreen controller of shelf life test chamber enables complex multi-stage profiles that more accurately represent real distribution challenges than static elevated temperature storage alone.

Testing Approach | Acceleration Factor | Typical Duration |

Ambient (25°C) Real-Time | 1× (baseline) | 12-24 months |

Accelerated (37°C) | 4-5× | 3-6 months |

High-Temperature (45°C) | 8-10× | 6-12 weeks |

Microbial Stability and Safety Assessment

Pathogen Challenge Studies

Certain beverage categories - particularly those with neutral pH or added nutrients - support microbial growth if contamination occurs. Challenge testing introduces specific organisms at known concentrations, then monitors survival and proliferation under various storage conditions. The chamber's humidity control creates ideal conditions for evaluating whether formulations prevent pathogen establishment.

Preservative System Efficacy

Natural and synthetic preservatives lose effectiveness over time through degradation or interaction with other ingredients. Longitudinal testing reveals the protective capacity duration, ensuring formulations maintain antimicrobial activity throughout claimed shelf life rather than creating vulnerability windows near expiration dates.

Indicator Organism Monitoring

While pathogen testing addresses safety, spoilage organisms affect quality through off-flavors, cloudiness, or gas production. Regular sampling during chamber testing tracks yeast, mold, and bacterial populations, identifying formulation weaknesses or packaging defects that permit contamination before products reach consumers.

Predictive Analysis for Shelf Life and Quality

Multivariate Statistical Modeling

Modern shelf life determination transcends simple pass-fail observations. Advanced statistical techniques analyze multiple quality parameters simultaneously - pH, color, flavor compounds, viscosity, separation tendency - building comprehensive degradation models. Data exported via the shelf life test chamber's USB port integrates with analytical software for sophisticated predictive modeling.

Sensory Evaluation Integration

Instrumental measurements provide objective data, but consumer perception ultimately determines marketability. Coordinating chamber testing with trained sensory panels at predetermined intervals identifies the precise point where chemical changes translate into noticeable quality decline, establishing scientifically grounded yet consumer-relevant expiration dates.

Remote Monitoring Capabilities

The network port equipped on LIB chambers enables real-time data access through laboratory networks or Wi-Fi connections. This connectivity allows quality teams to track ongoing experiments remotely, receive alerts when critical parameters deviate, and maintain continuous documentation for regulatory compliance without constant physical presence.

Quality Parameter | Measurement Method | Critical Threshold |

pH Stability | Electronic probe monitoring | ±0.3 units from initial |

Color Retention | Spectrophotometric analysis | ΔE < 2.0 (noticeable change) |

Dissolved Oxygen | Optical sensor tracking | <0.5 ppm for sensitive products |

Maintain Beverage Consistency with LIB Industry's Stable Shelf Life Test Chamber

| Name | shelf life test chamber | |||||

Model | TH-100 | |||||

Temperature range | -20℃ ~+150 ℃ | |||||

Low type | A: -40℃ B:-70℃ C -86℃ | |||||

Humidity Range | 20%-98%RH | |||||

Temperature deviation | ± 2.0 ℃ | |||||

Heating rate | 3 ℃ / min | |||||

Cooling rate | 1 ℃ / min | |||||

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | |||||

Exterior material | Steel Plate with protective coating | |||||

Interior material | SUS304 stainless steel | |||||

Standard configuration | 1 Cable hole (Φ 50) with plug; 2 shelves | |||||

Timing Function | 0.1~999.9 (S,M,H) settable | |||||

Advanced Temperature Uniformity Technology

The forced air convection system in LIB chambers ensures ±2.0°C temperature deviation throughout the testing volume, eliminating hot spots or cold zones that could skew results. This uniformity proves critical when testing multiple product variants simultaneously, ensuring each sample experiences identical stress conditions for valid comparisons.

Customization for Specialized Applications

Beyond standard configurations, LIB's engineering team designs modified chambers addressing unique industry requirements. Explosion-proof variants accommodate alcohol-based products; low-pressure modules simulate high-altitude distribution; vibration integration replicates transportation stress. This flexibility transforms the chamber from testing equipment into a comprehensive validation platform.

Simplified Maintenance and Operation

The mirror-finish stainless steel interior resists staining from spoilage events while facilitating rapid cleaning between test cycles. Beverage testing often involves samples that may leak, ferment, or develop mold - conditions that would compromise lesser chambers. The thoughtful design minimizes downtime and maintains testing schedule integrity.

Long-Term Reliability and Support

Shelf life test chambers represent significant capital investments that must deliver consistent performance across years of continuous operation. LIB Industry's environmentally friendly R404A and R23 refrigerant systems, combined with robust construction, ensure operational longevity. Comprehensive commissioning, installation, and training services accelerate laboratory integration and optimize return on investment.

Conclusion

Shelf life testing chambers have evolved from optional quality tools into essential infrastructure for competitive beverage manufacturing. These precision instruments compress time, control variables, and generate the predictive data that transforms product development from guesswork into science. As consumer expectations rise and regulatory scrutiny intensifies, manufacturers investing in comprehensive testing capabilities position themselves for sustainable success across global markets.

FAQs

What temperature range is necessary for comprehensive beverage shelf life testing?

Most beverage testing requires capabilities spanning refrigerated conditions around 4°C through elevated accelerated aging temperatures of 37-45°C. The LIB TH-225 chamber's -86°C to +150°C range exceeds these requirements, accommodating frozen product evaluation, extreme heat stress testing, and specialized applications beyond conventional beverage assessment.

How does humidity control impact beverage packaging testing accuracy?

Humidity directly affects packaging barrier properties, adhesive performance, and label integrity - all critical factors in maintaining product quality during distribution. Testing across the 20-98% RH range reveals how packaging performs in arid climates versus humid tropical environments, identifying potential failure modes before market introduction.

Can shelf life chambers accommodate different beverage container sizes and formats?

The perforated stainless steel shelving in LIB chambers adjusts to accommodate various package formats from individual bottles to multi-pack configurations. The TH-225 (500×600×750mm) and TH-500 (700×800×900mm) internal dimensions provide flexibility for testing standard containers alongside emerging packaging innovations without compromising temperature and humidity uniformity.

Ready to elevate your beverage quality assurance program? LIB Industry stands as a leading manufacturer and supplier of shelf life test chambers, delivering CE-approved solutions backed by decades of environmental simulation expertise. Contact our technical team at ellen@lib-industry.com to discuss custom configurations tailored to your specific testing requirements and discover how our turn-key approach streamlines your path from specification to operational excellence.