In today's competitive market, product reliability is crucial. Even small amounts of dust can affect performance, shorten product lifespan, and lead to unexpected failures. Dust test chambers offer manufacturers a precise, controlled environment to evaluate how products perform under dust exposure, helping ensure durability, safety, and consistent quality in real-world conditions.

Our Dust Proof Test Chambers have earned positive feedback from clients, including a U.S.-based lighting manufacturer, who noted that their chamber “performed reliably.” This demonstrates the dependability of our equipment in practical testing scenarios. By using these chambers, manufacturers can accurately assess dust resistance, identify potential vulnerabilities, and implement improvements—ensuring products are robust, safe, and market-ready.

Outdoor electrical enclosures face relentless exposure to dust, sand, and airborne particles that can compromise their functionality and safety. A dust proof test chamber provides manufacturers with a controlled environment to validate whether their enclosures meet specified Ingress Protection (IP) ratings before deployment. This specialized equipment simulates harsh environmental conditions, allowing engineers to identify sealing weaknesses, evaluate material durability, and ensure compliance with international standards like IEC 60529 and ISO 20653. By subjecting products to accelerated dust exposure, manufacturers can confidently certify that their outdoor enclosures will protect sensitive electronics from particle ingress throughout their operational lifespan.

What is IP Rating and Its Importance?

Understanding the IP Rating System

The Ingress Protection rating system classifies the degree of protection an enclosure provides against solid particles and liquids. The two- digit code following "IP" indicates specific protection levels - the first digit (0-6) addresses solid particle ingress, while the second (0-8) covers liquid ingress. An enclosure rated IP6X demonstrates complete dust-tightness, meaning no particles can penetrate the housing under test conditions.

digit code following "IP" indicates specific protection levels - the first digit (0-6) addresses solid particle ingress, while the second (0-8) covers liquid ingress. An enclosure rated IP6X demonstrates complete dust-tightness, meaning no particles can penetrate the housing under test conditions.

Critical Applications Requiring Dust Protection

Outdoor electrical installations demand robust dust protection across multiple industries. Telecommunications infrastructure, solar panel junction boxes, railway signaling equipment, and industrial control cabinets all require verified particle resistance. Without proper dust sealing, fine particles infiltrate internal components, causing short circuits, mechanical wear, and premature equipment failure that results in costly downtime and safety hazards.

Regulatory Compliance and Market Access

Achieving certified IP ratings opens global market opportunities and satisfies mandatory safety regulations. Many regional standards reference IEC 60529 as the baseline for environmental protection. Manufacturers lacking proper IP certification face market rejection, liability exposure, and reputation damage. Independent laboratory testing using calibrated dust chambers provides the documentation needed for regulatory approval and customer confidence.

Simulating Outdoor Environmental Conditions

Replicating Real-world Dust Concentration

Outdoor environments contain varying particle densities depending on geographic location and seasonal conditions. Desert regions, construction sites, and agricultural zones present particularly challenging dust concentrations. Test chambers recreate these conditions by maintaining controlled dust concentrations between 2-4 kg/m³, which represents severe exposure scenarios. This concentration allows meaningful evaluation within compressed timeframes compared to years of natural exposure.

construction sites, and agricultural zones present particularly challenging dust concentrations. Test chambers recreate these conditions by maintaining controlled dust concentrations between 2-4 kg/m³, which represents severe exposure scenarios. This concentration allows meaningful evaluation within compressed timeframes compared to years of natural exposure.

Temperature Control During Dust Testing

Environmental temperature significantly influences enclosure materials and sealing mechanisms. Rubber gaskets, adhesives, and plastic components respond differently to thermal variations. Testing at elevated temperatures up to 50°C simulates summer conditions where thermal expansion may create gaps in sealing interfaces. Combined temperature and dust exposure reveals vulnerabilities that single-variable testing might overlook.

Vacuum Pressure Simulation for Breathing Effects

Many outdoor enclosures experience pressure differentials due to temperature cycling, creating a "breathing" effect that draws particles inward. Advanced dust proof test chambers incorporate vacuum systems with adjustable pressure to replicate this phenomenon. The pressure gauge, air filter, and regulator combination enables precise control of differential pressure, simulating how enclosures behave when cooling after sun exposure or during rapid weather changes.

Standard Dust Test Conditions for IP5X and IP6X Ratings

IP Rating | Dust Type | Concentration | Test Duration | Pressure Differential | Acceptance Criteria |

IP5X | Talcum powder (50μm) | 2 kg/m³ | 8 hours | 20 mbar vacuum | Limited ingress permitted |

IP6X | Talcum powder (50μm) | 2 kg/m³ | 8 hours | 20 mbar vacuum | Zero dust ingress |

Testing Enclosure Sealing Performance Against Dust

Identifying Vulnerable Entry Points

Dust infiltration typically occurs through predictable pathways: cable glands, panel seams, ventilation openings, and mounting hardware interfaces. Chamber testing systematically exposes these potential entry points to sustained particle bombardment. Post-test inspection reveals whether gaskets compressed adequately, if thread engagement on cable glands achieved proper sealing, and whether ventilation filters maintained integrity under pressure.

Evaluating Gasket Material Compatibility

Gasket selection directly impacts long-term dust resistance. Silicone, EPDM, neoprene, and foam gaskets each exhibit different compression characteristics, temperature tolerance, and aging properties. Dust chamber testing validates whether the chosen gasket material maintains effective sealing under combined dust and thermal stress. Manufacturers can compare multiple gasket options in parallel tests to optimize cost-performance balance.

Assessing Filter and Breather Effectiveness

Enclosures requiring internal air circulation incorporate filtered vents or pressure equalization breathers. These components must prevent particle ingress while allowing airflow or pressure equalization. Dust testing verifies filter media efficiency, housing seal integrity, and whether protective grilles prevent filter damage. The 75μm nominal gap between test wires ensures realistic particle challenge without clogging the chamber.

Accelerated Aging for Long-term Enclosure Durability

Compressed Lifecycle Testing Methodology

Natural weathering requires years to reveal durability weaknesses, but manufacturers need faster validation. Accelerated dust testing condenses decades of exposure into weeks by intensifying particle concentration and exposure duration. Programmable controllers enable multi-cycle testing that alternates between dust exposure and rest periods, simulating day-night or seasonal patterns while accumulating particle stress rapidly.

Material Degradation Assessment

Prolonged dust exposure combined with temperature cycling reveals material degradation mechanisms. Plastics may become brittle from UV-stabilizer depletion (simulated through thermal stress), coatings develop micro-cracks, and metal surfaces show corrosion initiation. Comparing specimens before and after extended dust proof test chamber exposure quantifies degradation rates and predicts field service life under specific environmental conditions.

Sealing System Fatigue Evaluation

Repeated pressure cycling during dust exposure tests the mechanical resilience of sealing systems. Gaskets experience compression set, adhesive bonds undergo stress relaxation, and snap-fit mechanisms face wear. Extended testing protocols running 99+ hours with periodic vacuum cycling reveal whether seals maintain effectiveness throughout the product's intended service interval or require maintenance schedules.

Accelerated Testing Protocol Example

Test Phase | Duration | Temperature | Dust Concentration | Vacuum Cycle | Purpose |

Initial Exposure | 24 hours | 40°C | 3 kg/m³ | None | Baseline sealing assessment |

Thermal Cycling | 48 hours | 25-50°C cycles | 2.5 kg/m³ | Every 4 hours | Seal fatigue evaluation |

Extended Endurance | 72 hours | 45°C | 4 kg/m³ | Every 2 hours | Long-term durability validation |

Material and Design Considerations for IP Compliance

Enclosure Material Selection Impact

Material choice fundamentally determines dust resistance potential. Die-cast aluminum provides excellent inherent dust-tightness but requires careful surface finishing. Polycarbonate enclosures offer design flexibility yet demand precise molding tolerances to achieve gapless assembly. Stainless steel 304 delivers superior corrosion resistance in coastal environments where salt particles accompany dust. Chamber testing validates whether material selection aligns with IP rating targets.

Design Features Enhancing Dust Protection

Specific design elements significantly improve dust resistance without increasing costs substantially. Labyrinth seals create tortuous paths that trap particles before reaching critical areas. Overlapping joints with gasket compression zones ensure continuous sealing perimeters. Recessed mounting hardware prevents fastener interfaces from becoming ingress pathways. Testing different design iterations identifies which features provide measurable protection improvements.

Trade-offs Between Protection and Functionality

Higher IP ratings sometimes conflict with operational requirements. Enclosures needing frequent access must balance dust-tightness against serviceable closures. Ventilation requirements for heat dissipation compete with particle exclusion. Chamber testing helps engineers optimize these trade-offs by quantifying how much protection specific design compromises actually sacrifice, enabling informed decisions rather than over-engineering.

Documentation and Reporting for IP Test Results

Comprehensive Test Record Requirements

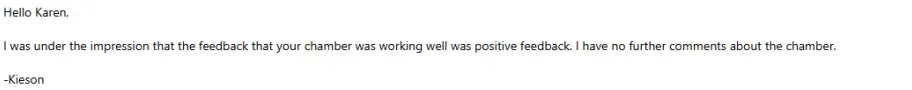

Regulatory bodies and customers demand detailed test documentation beyond simple pass/fail verdicts. Proper reports include chamber calibration certificates, environmental conditions throughout testing, specimen preparation methods, photographic evidence of pre/post-test conditions, and measured particle deposition quantities. The programmable controller's data logging capability via Ethernet connection enables automated record generation with timestamped parameters.

Certification Process and Laboratory Standards

Achieving recognized IP certification requires testing at accredited facilities following ISO/IEC 17025 laboratory standards. While in-house chambers enable development testing, third-party validation provides market-accepted certification. Internal testing using dust proof test chamber generates preliminary data guiding design refinement, reducing costly certification failures. Understanding what certifying bodies evaluate helps manufacturers prepare specimens and documentation appropriately.

Traceability and Ongoing Compliance Verification

IP ratings represent point-in-time validation, but manufacturing variations require ongoing verification. Establishing traceability between certified prototypes and production units involves periodic sampling and testing. Documentation systems linking chamber test results to production batches, material lot numbers, and supplier certifications demonstrate continuous compliance. This traceability becomes critical when investigating field failures or addressing customer quality audits.

Essential IP Test Documentation Elements

Documentation Category | Required Information | Purpose |

Equipment Calibration | Chamber certification, dust composition analysis, measurement device calibration dates | Ensure test validity and repeatability |

Test Specimen Details | Serial numbers, photographs, dimensional measurements, pre-test condition assessment | Establish baseline and enable correlation |

Test Parameters | Temperature logs, dust concentration readings, vacuum pressure records, duration timestamp | Prove standard compliance |

Results Analysis | Particle deposition measurements, seal integrity assessment, photographic evidence | Demonstrate performance against criteria |

Validate Outdoor Enclosures with LIB Industry's Precise Dust Proof Test Chamber

|

|

| Name | dust proof test chamber |

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3 mm |

Internal Diameter of IPX6 Nozzle | 12.5 mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

Advanced Chamber Design Features

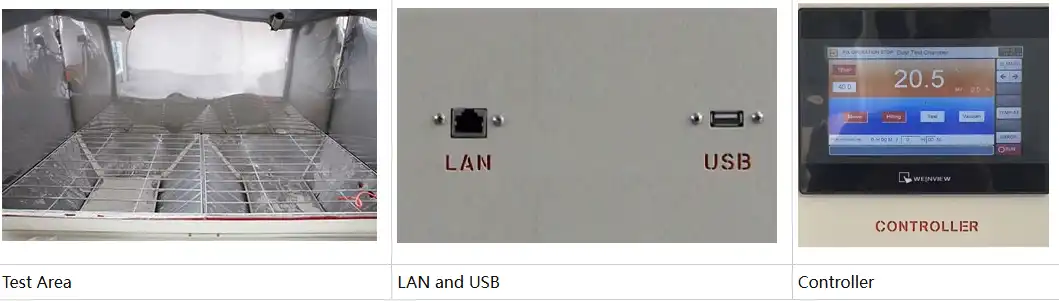

LIB Industry's dust chambers incorporate specialized design elements optimizing IP testing accuracy. The 304 stainless steel interior resists corrosion from aggressive test dust while maintaining surface cleanliness between tests. The large observation window with dust scraper enables real-time monitoring without contaminating the test environment. Electromagnetic door locks ensure complete sealing during pressurized testing, preventing false failure results from chamber leakage rather than specimen weakness.

Flexible Testing Configuration Options

Available in 800L and 1000L capacities, LIB chambers accommodate various enclosure sizes from compact junction boxes to large cabinet assemblies. The programmable color LCD touchscreen controller simplifies complex test protocol setup with intuitive navigation. Dust-proof power outlets rated for 16A enable testing of energized equipment, revealing whether electrical operation influences sealing performance. Three-position adjustable pressure settings facilitate testing across multiple IP rating levels without equipment changes.

Technical Support and Application Engineering

Beyond equipment supply, LIB Industry provides comprehensive support including installation, commissioning, and operator training. Technical specialists assist in developing test protocols matching specific product requirements and industry standards. Ongoing consultation helps manufacturers interpret results, troubleshoot unexpected failures, and optimize enclosure designs based on test findings. This partnership approach accelerates time-to-market while ensuring robust product validation.

Conclusion

Dust proof test chambers transform IP rating validation from uncertain field observation into controlled, repeatable laboratory verification. These systems enable manufacturers to confidently design outdoor enclosures meeting stringent environmental protection standards through systematic testing of sealing performance, material durability, and long-term reliability. Investing in proper dust testing infrastructure reduces warranty claims, enhances product reputation, and opens access to regulated markets requiring certified environmental protection.

FAQs

What is the difference between IP5X and IP6X dust protection ratings?

IP5X indicates dust-protected enclosures where limited particle ingress is permitted but insufficient to interfere with operation. IP6X represents dust-tight enclosures with absolutely no particle penetration. Testing duration and methods remain identical, but acceptance criteria differ significantly. Most outdoor critical applications require IP6X certification for long-term reliability.

How long does typical dust chamber testing take for IP certification?

Standard IP5X/IP6X testing requires eight continuous hours of dust exposure under specified conditions, plus preparation and post-test inspection time. Complete testing including documentation typically spans two days. Accelerated aging protocols for durability assessment may extend testing to several weeks depending on lifecycle simulation requirements and manufacturer objectives.

Can dust chambers test enclosures while electrically energized?

Yes, advanced dust chambers include dust-proof power outlets enabling testing of energized equipment. This capability reveals whether electrical heating, vibration from internal components, or electromagnetic effects influence sealing performance. Testing under operational conditions provides more realistic validation than passive specimen evaluation, particularly for enclosures with active thermal management systems.

Partner with LIB Industry for Your Environmental Testing Needs

As a leading dust proof test chamber manufacturer and supplier, LIB Industry delivers turn-key environmental testing solutions customized to your specifications. Our factory-direct pricing and expert engineering support ensure you obtain reliable equipment backed by comprehensive service. Contact ellen@lib-industry.com to discuss your IP testing requirements and receive a detailed quotation.