Key Factors Affecting Xenon Arc Weathering Test Accuracy

Xenon arc weathering test accuracy depends on controlling multiple interconnected variables throughout the exposure cycle. Irradiance intensity and spectral distribution must remain consistent, while black panel temperature (BPT) and relative humidity need precise regulation to simulate real-world conditions. Sample positioning, rotation speed, and mounting techniques significantly impact exposure uniformity. Lamp aging characteristics, filter degradation, and calibration frequency directly influence spectral output. Water spray timing, droplet size, and drying phases affect material interaction with moisture. Xenon arc weatherometer temperature stability, airflow patterns, and radiometer accuracy complete the critical parameter set. Understanding how these elements interact enables laboratories to achieve reproducible results that correlate with outdoor weathering performance.

What Parameters Most Strongly Influence Test Repeatability?

Spectral Power Distribution Control

The xenon arc lamp generates a broad-spectrum output that approximates natural sunlight when properly filtered. Maintaining consistent spectral power

distribution across the 300-400nm ultraviolet range requires attention to filter condition and lamp power stability. Variations in UV irradiance levels exceeding ±5% can produce measurably different degradation rates in polymer samples. The 4500W water-cooled lamp system delivers controlled energy output, but spectral drift occurs as electrodes erode and arc gap dimensions change during operation.

Black Panel Temperature Precision

BPT represents the actual surface temperature experienced by exposed specimens under combined radiant and ambient heating. The 35-85°C range allows simulation of diverse climate zones, but ±2°C tolerance demands sophisticated thermal management. Temperature gradients within the chamber create hot and cold zones that produce non-uniform aging. Specimens positioned near thermal boundaries experience accelerated or decelerated degradation compared to those in stable temperature regions, making rotation essential.

Relative Humidity Stabilization

Moisture content affects photochemical reaction rates and hydrolytic degradation mechanisms in many materials. The 30-98% RH range accommodates both arid and tropical exposure simulations, but achieving ±3% RH stability requires precise water vapor injection and condensation control. Humidity fluctuations alter the rate of water absorption into polymeric materials, changing their susceptibility to UV-induced chain scission. Textiles and coatings show particularly strong humidity-dependent aging responses.

Irradiance Uniformity and Sensor Calibration

Radiometric Measurement Accuracy

UV radiometers measure irradiance within specific wavelength bands to verify exposure intensity. The ±5% tolerance specification represents the combined uncertainty from sensor calibration, spectral response matching, and positional geometry. Radiometers require annual recalibration against reference standards traceable to national metrology institutes. Drift in radiometer sensitivity produces systematic errors that compound over extended test periods, leading to under-exposure or over-exposure relative to specified conditions.

Chamber Geometry and Sample Distance

The rotating sample holder maintains consistent lamp-to-specimen distance as samples orbit the central light source. Distance variations of just 2-3 centimeters can alter irradiance by 10-15% due to inverse square law effects. The 950×950×850mm internal chamber dimensions establish optimal spacing for the 1r/min rotation speed, ensuring each specimen receives equivalent integrated exposure. Overloading the sample rack or improper mounting introduces geometric variations that compromise uniformity.

Filter System Performance

Inner quartz and outer borosilicate filters in a xenon arc weatherometer shape the xenon arc spectrum to match specific standards like JIS C8912 or JIS K 5600-7-7. Quartz transmits short-wavelength UV while blocking infrared, whereas borosilicate absorbs UVC below 295 nm to simulate atmospheric ozone filtration. Filter degradation from solarization and thermal stress gradually shifts transmission characteristics. Replacement intervals based on lamp hours prevent spectral drift that would invalidate test conditions.

Parameter | Target Value | Tolerance | Impact on Accuracy |

UV Irradiance (300-400nm) | 150 W/m² | ±5% | Directly affects photodegradation rate |

Black Panel Temperature | 35-85°C | ±2°C | Controls thermal aging component |

Relative Humidity | 30-98% RH | ±3% | Influences hydrolysis and moisture uptake |

Temperature, Humidity, and Water Spray Control

Chamber Air Temperature Management

The -40 to 100°C chamber temperature range with ±2°C control enables testing across extreme climate conditions. Polyurethane foam and insulation cotton minimize heat loss while maintaining spatial uniformity. Temperature stratification creates vertical gradients where upper specimens experience warmer conditions than lower ones. Forced air circulation systems reduce stratification but introduce airflow-dependent cooling that affects surface temperatures differently than radiant heating alone.

Water Spray Cycle Programming

The 1-9999H59M adjustable water spray cycle simulates rain, dew, and condensation exposure. Spray duration, droplet size, and water temperature all influence material response. Cold water spray on hot specimens produces thermal shock that accelerates cracking in brittle coatings. Spray coverage uniformity depends on nozzle design and positioning relative to rotating samples. Insufficient drainage creates pooling that produces localized overexposure to moisture, while inadequate wetting fails to activate hydrolytic mechanisms.

Drying Phase Optimization

The interval between water spray cessation and the next wetting cycle allows surface drying and enables specific degradation mechanisms. Some polymers require dry conditions for photo-oxidation to proceed, while others degrade primarily during wet phases when oxygen permeability increases. Drying rate depends on temperature, humidity, and airflow velocity. Incomplete drying leaves surface moisture that alters subsequent UV absorption and scattering, particularly in porous materials like textiles.

Specimen Mounting, Orientation, and Exposure Consistency

Sample Holder Configuration

The adjustable-speed rotating holder ensures each specimen receives equivalent time-averaged exposure as it orbits the lamp. The 1r/min rotation rate completes one circuit every 60 minutes, averaging out any residual irradiance non-uniformities. Samples mounted at different radial positions experience identical rotation but may see slightly different irradiance intensities if lamp output shows directional variations. Proper loading balances the holder to prevent wobble that would create distance fluctuations.

Specimen Preparation and Mounting

Sample thickness, backing material, and edge sealing all affect thermal coupling between the specimen and xenon arc weatherometer environment. Thick samples with low thermal conductivity exhibit higher surface temperatures than thin films with good thermal contact. Backing materials should match the intended end-use configuration to reproduce realistic heat transfer. Edge sealing prevents moisture ingress through cut edges that wouldn't occur in actual products, avoiding artificially accelerated degradation at specimen perimeters.

Exposure Angle and Light Incidence

Most xenon arc weatherometers expose samples at perpendicular incidence to maximize UV flux and accelerate aging. This differs from outdoor exposure where time-averaged incident angles vary with solar position and season. Some materials show strong angle-dependent degradation due to anisotropic structure or surface texture. Textiles with directional weave patterns may age differently depending on fiber orientation relative to the incident beam, requiring careful sample positioning for consistency.

Mounting Factor | Best Practice | Common Error |

Sample Positioning | Maintain consistent radial distance | Uneven rack loading |

Backing Material | Match end-use substrate | Using arbitrary mounting |

Edge Treatment | Seal cut edges when appropriate | Exposing unprotected edges |

Lamp Aging Effects and Maintenance Practices

Xenon Arc Lamp Degradation

The 4500W water-cooled lamp gradually changes output characteristics as electrodes erode and internal gas pressure shifts. Initial run-in produces stabilization after 50-100 hours, followed by gradual spectral drift and intensity decline over 1500-2000 hours of operation. UV output in the 300-400nm band decreases faster than visible wavelengths, changing the spectrum's aging potential. Manufacturers specify lamp replacement intervals based on irradiance monitoring, but spectral measurements provide more complete characterization.

Cooling System Maintenance

Water-cooled lamp systems prevent overheating while removing infrared radiation that would otherwise elevate chamber temperature beyond controllable limits. Cooling water quality affects heat transfer efficiency and prevents mineral deposits on quartz envelopes. Distilled or deionized water minimizes scaling, while proper flow rates ensure adequate cooling without excessive turbulence. Temperature differentials between coolant and lamp envelope should remain within design specifications to prevent thermal stress fractures.

Filter Replacement Protocols

Both quartz and borosilicate filters experience cumulative radiation damage that alters transmission characteristics. Solarization effects cause permanent absorption bands to develop, reducing UV transmission and shifting the spectral peak. Manufacturers provide replacement schedules based on cumulative exposure hours, but transmission measurements identify premature degradation. Replacing filters according to these schedules maintains spectral consistency across multiple test campaigns.

Maintenance Activity | Frequency | Performance Impact |

Radiometer Calibration | Annual | Ensures accurate irradiance measurement |

Lamp Replacement | 1500-2000 hours | Maintains spectral output |

Filter Inspection | Every 500 hours | Prevents spectral drift |

Cooling System Service | Quarterly | Ensures proper temperature control |

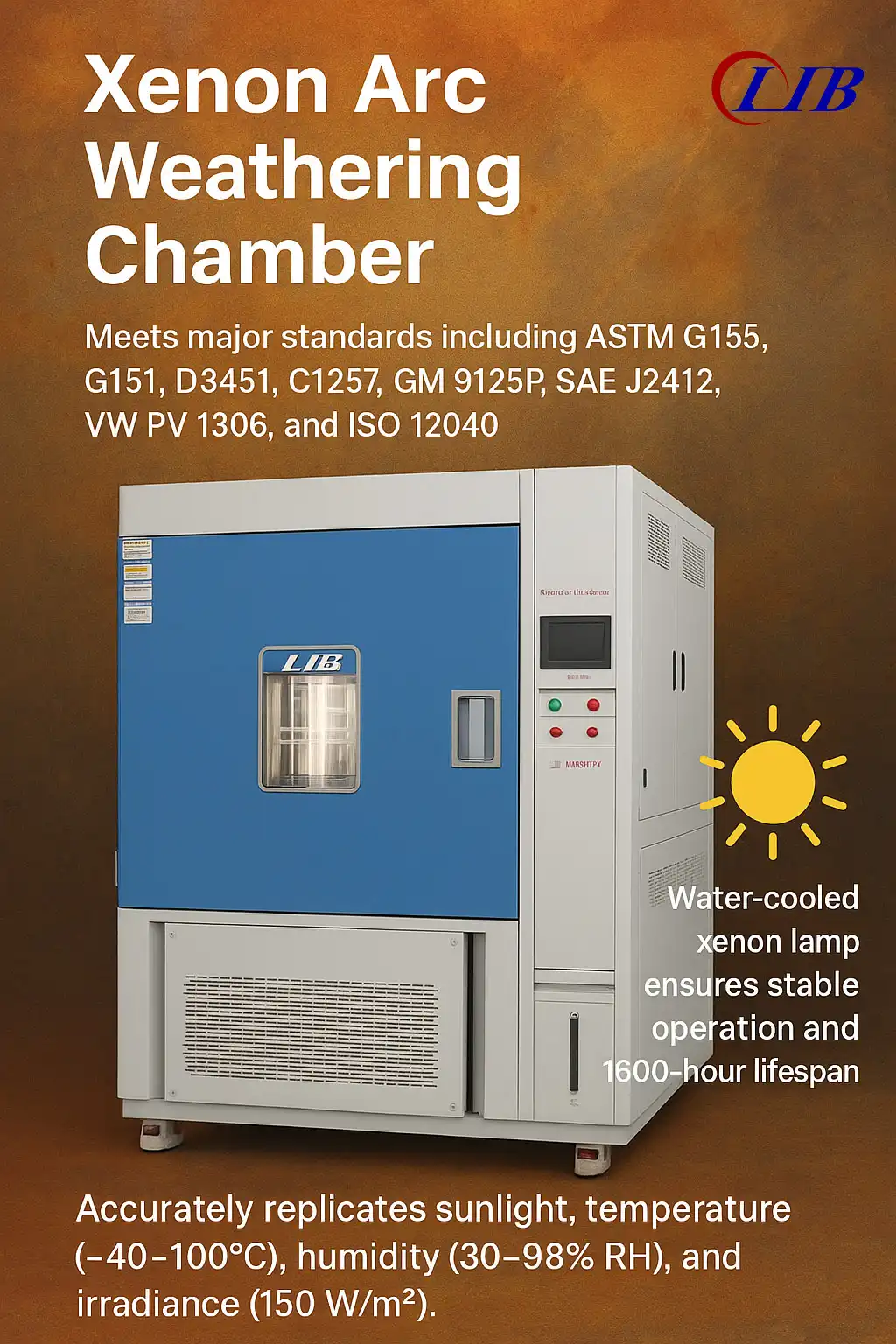

Guarantee Precise Data with LIB Industry's Advanced Xenon Arc Weatherometer

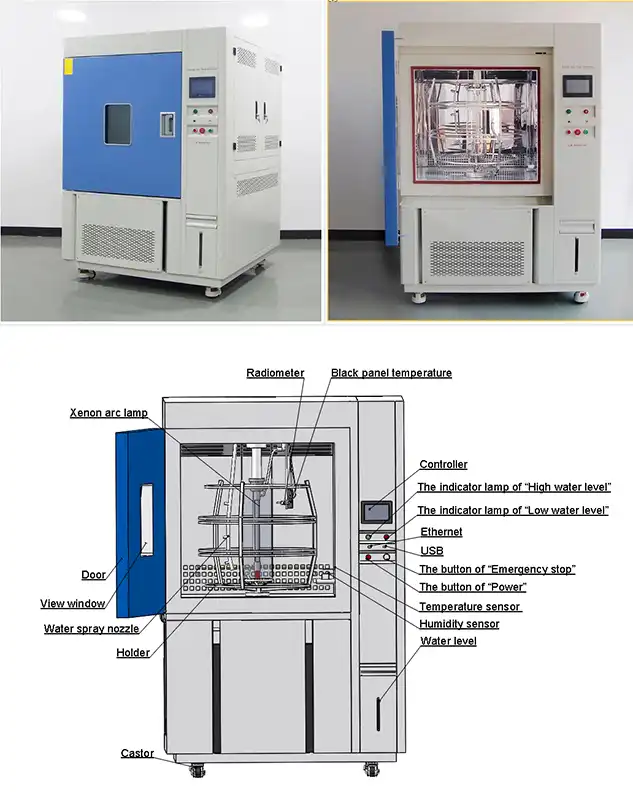

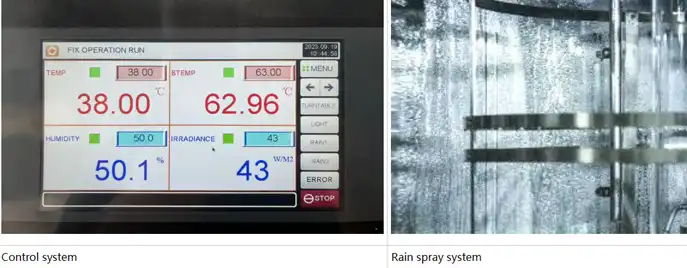

Integrated Control System Features

The programmable color LCD touch screen controller coordinates all test parameters through a unified interface. Real-time monitoring displays irradiance, BPT, chamber temperature, and humidity simultaneously, allowing operators to verify stable conditions before starting exposures. Data logging captures parameter variations throughout extended test cycles, providing documentation for quality systems and regulatory compliance. The controller's closed-loop algorithms adjust heating, cooling, and humidification outputs to maintain setpoints despite ambient laboratory condition changes.

Quality Assurance Capabilities

The XL-S-750C xenon arc weatherometer incorporates design features that enhance test-to-test reproducibility. SUS304 stainless steel interior surfaces resist corrosion from water spray cycles and humid conditions while maintaining cleanliness that prevents contamination. Double-layer thermo-stability silicone rubber sealing on observation windows allows progress monitoring without opening the chamber and disrupting conditions. Interior lighting enables photography and visual inspection during pauses in the exposure cycle.

Standards Compliance and Validation

Compliance with JIS C8912, JIS K 5600-7-7, and JIS K 7350-2 standards ensures the xenon arc weatherometer produces results accepted for regulatory submissions and material specifications. Each standard defines specific spectral requirements, exposure geometries, and control tolerances. Pre-delivery validation testing verifies that irradiance uniformity, temperature control, and humidity stability meet specification limits. Customers receive calibration certificates and performance documentation that support ISO/IEC 17025 laboratory accreditation.

Conclusion

Xenon arc weathering test accuracy emerges from controlling irradiance intensity, spectral distribution, temperature, humidity, and specimen positioning within tight tolerances. Regular calibration, preventive maintenance, and adherence to standardized protocols ensure reproducible results. Lamp aging, filter degradation, and radiometer drift require systematic monitoring and replacement schedules. Advanced weathering systems like LIB Industry's XL-S-750C integrate precise controls and quality features that minimize sources of variability, enabling confident material selection and product development decisions based on accelerated aging data.

FAQ

How often should xenon arc lamps be replaced to maintain test accuracy?

Xenon lamps typically require replacement after 1500-2000 operating hours when UV output degrades beyond acceptable tolerances. Regular radiometer measurements track intensity decline, while spectral analysis confirms wavelength distribution remains within standards. Preventive replacement before complete failure maintains consistent exposure conditions.

What causes differences between xenon weathering results and outdoor exposure?

Accelerated testing concentrates UV exposure and controls moisture cycles that occur randomly outdoors. Temperature cycling patterns, spectral distribution differences, and absence of pollutants create variations. Correlation studies establish acceleration factors for specific materials, typically ranging from 3:1 to 8:1 compared to outdoor exposure.

Can one xenon weatherometer accommodate multiple test standards simultaneously?

Chamber configuration with appropriate filters and programming allows sequential testing to different standards. However, simultaneous testing requires conditions to satisfy the most stringent requirements of all applicable standards. Irradiance levels, temperature ranges, and humidity specifications often differ between standards, necessitating separate test campaigns for rigorous compliance.

Contact LIB Industry for Expert Environmental Testing Solutions

As a leading environmental test chamber manufacturer and supplier, LIB Industry delivers turn-key xenon arc weatherometer systems with comprehensive installation, commissioning, and training support. Reach our technical team at ellen@lib-industry.com for detailed specifications, custom configurations, and application guidance tailored to your testing requirements.