Using a UV Resistance Test Chamber for Printed Circuit Board UV Testing

Printed circuit boards (PCBs) used in outdoor electronics, automotive systems, and aerospace applications are continuously exposed to ultraviolet radiation that can accelerate material aging and compromise long-term reliability. A UV resistance test chamber enables manufacturers to simulate real-world UV, temperature, and moisture conditions under controlled laboratory settings, allowing engineers to evaluate the durability of PCB substrates, solder masks, and protective coatings before products enter the market.

This reliability is not only theoretical but proven in real applications. As confirmed by customer feedback after installation, “Works perfectly fine now”, the UV resistance test chamber delivers stable operation and dependable performance in daily testing. Such consistent results make the chamber an integral part of PCB qualification workflows, ensuring confidence in accelerated aging data while supporting efficient, repeatable, and standards-compliant UV testing from the very first use.

Printed circuit boards (PCBs) deployed in outdoor electronics, automotive systems, and aerospace applications face relentless ultraviolet radiation that gradually compromises their structural integrity and functional reliability. A UV resistance test chamber provides manufacturers with precise environmental simulation capabilities to evaluate how protective coatings, substrate materials, and solder mask layers withstand prolonged UV exposure. By subjecting PCBs to accelerated weathering conditions with controlled irradiance levels, temperature cycles, and moisture variation, engineers can identify potential failure modes before production, ensuring products meet stringent durability standards for their intended operational lifespan.

Why PCBs Require UV Resistance Testing?

Outdoor Electronic Applications Demand Enhanced Durability

PCBs installed in solar inverters, LED street lighting systems, and outdoor signage experience continuous exposure to solar radiation. The photochemical reactions triggered by UV wavelengths between 290-400nm cause polymer chain scission in substrate materials, leading to embrittlement and dimensional instability. Testing these assemblies in controlled laboratory environments reveals degradation patterns that might take years to manifest in field conditions.

radiation. The photochemical reactions triggered by UV wavelengths between 290-400nm cause polymer chain scission in substrate materials, leading to embrittlement and dimensional instability. Testing these assemblies in controlled laboratory environments reveals degradation patterns that might take years to manifest in field conditions.

Regulatory Compliance Across Multiple Industries

Automotive electronics manufacturers must satisfy IEC 60068-2-5 and SAE J2527 standards, which mandate specific UV exposure thresholds. Aerospace components require MIL-STD-810 compliance, while consumer electronics targeting outdoor markets need verification against UL 746C protocols. A UV resistance test chamber enables systematic validation against these requirements through programmable test sequences.

Cost Reduction Through Early Failure Detection

Identifying UV-susceptible components during the design phase prevents expensive product recalls and warranty claims. When a conformal coating proves inadequate during accelerated testing, engineers can reformulate or select alternative materials before committing to mass production, saving substantial capital investment and protecting brand reputation.

Effects of UV Exposure on PCB Materials and Coatings

Photodegradation of Polymer-Based Substrates

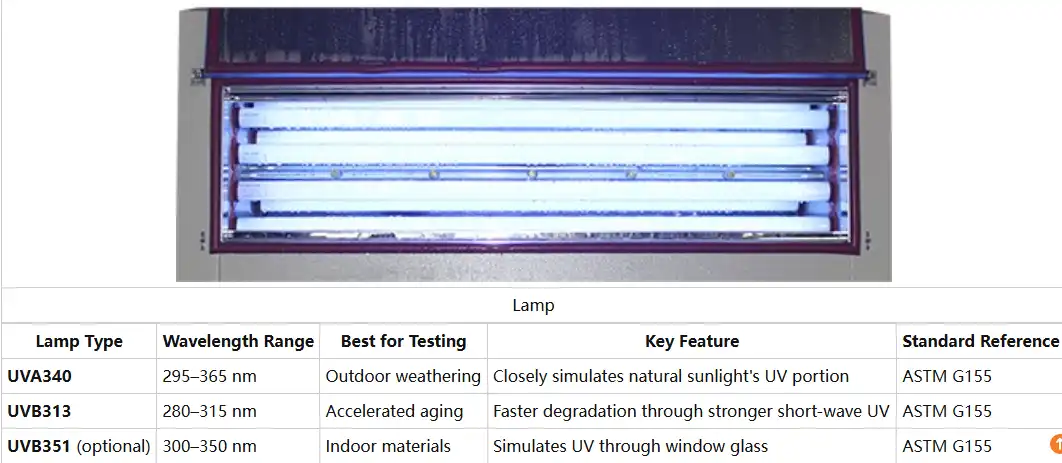

FR-4 epoxy laminates, the most common PCB substrate material, contain aromatic structures that absorb UV energy. This absorption initiates oxidative degradation, causing yellowing, surface chalking, and reduced dielectric strength. Polyimide flexible circuits experience similar photochemical breakdown, with extended exposure producing microcracks that compromise electrical insulation. Chamber testing with UVA-340 lamps replicates the solar spectrum's most damaging wavelengths.

absorption initiates oxidative degradation, causing yellowing, surface chalking, and reduced dielectric strength. Polyimide flexible circuits experience similar photochemical breakdown, with extended exposure producing microcracks that compromise electrical insulation. Chamber testing with UVA-340 lamps replicates the solar spectrum's most damaging wavelengths.

Solder Mask Deterioration and Color Shifts

Green, blue, and white solder masks exhibit distinct UV sensitivity profiles. Pigments undergo photofading, while the protective polymer matrix becomes brittle and susceptible to moisture ingress. Quantitative colorimetry measurements before and after chamber exposure document these changes, providing objective data for material qualification decisions.

Conformal Coating Performance Degradation

Acrylic, silicone, and urethane conformal coatings applied to PCBs for environmental protection face their own UV challenges. Irradiance levels of 0.68 W/m² at 340nm - achievable in the UV-SI-260 chamber - simulate decades of outdoor exposure within weeks. Post-test adhesion evaluations, moisture resistance checks, and insulation resistance measurements reveal whether protective layers maintain their barrier properties.

PCB Material Component | Primary UV Degradation Effect | Observable Changes |

FR-4 Substrate | Polymer chain scission | Yellowing, embrittlement, reduced flexural strength |

Solder Mask | Pigment photofading | Color shift, surface chalking, cracking |

Conformal Coating | Cross-link breakdown | Loss of adhesion, moisture permeability increase |

Copper Traces | Oxidation acceleration | Increased resistance, connection reliability issues |

Simulating Environmental Conditions for Electronic Components

Combined UV and Thermal Cycling Protocols

Real-world outdoor electronics experience temperature swings alongside UV bombardment. Programming the UV resistance test chamber to alternate between 70°C irradiation phases and 50°C condensation periods with ≥95% relative humidity replicates diurnal thermal stress patterns. This synergistic exposure reveals weaknesses that single-factor testing might overlook.

Moisture Condensation and Water Spray Functions

The ten-nozzle spray system in advanced chambers delivers controlled water deposition at 0.8-1.0mm per 80cm² per hour. This moisture exposure simulates dew formation and rain events, testing whether UV-degraded surfaces allow water infiltration that could cause corrosion or electrical shorts. The programmable water spray cycle supports customized test profiles matching specific geographic climates.

Bandwidth Precision for Spectrum-Specific Testing

The 290-400nm bandwidth capability covers both UVB (280-315nm) and UVA (315-400nm) ranges. UVB-313 lamps provide maximum acceleration for rapid screening tests, while UVA-340 lamps offer superior correlation with actual outdoor weathering. This flexibility allows test engineers to balance test duration against real-world accuracy based on project requirements.

Accelerated Aging Techniques for PCB Reliability

Irradiance Intensity Adjustment for Time Compression

Standard sunlight delivers approximately 0.55 W/m² at 340nm at solar noon. By elevating chamber irradiance to 1.55 W/m², test durations compress by a factor of 2.8, enabling three-year outdoor exposure simulation in roughly one year of continuous testing. The UV-SI-260's 0.3-20 W/m² irradiance control range accommodates various acceleration factors while maintaining test validity.

compress by a factor of 2.8, enabling three-year outdoor exposure simulation in roughly one year of continuous testing. The UV-SI-260's 0.3-20 W/m² irradiance control range accommodates various acceleration factors while maintaining test validity.

Temperature-Enhanced Degradation Kinetics

Increasing the black panel temperature from 50°C to 70°C approximately doubles the rate of many photochemical reactions according to Arrhenius kinetics. Combined with elevated irradiance, this creates highly accelerated test conditions suitable for preliminary material screening, though correlation studies with natural weathering remain essential for accurate lifetime predictions.

Cyclic Testing Versus Continuous Exposure

Alternating UV exposure, dark condensation, and water spray cycles more accurately represents outdoor conditions than continuous irradiation. A typical automotive qualification protocol might specify 4 hours of UV at 60°C black panel temperature, followed by 4 hours of condensation at 50°C, repeated for 1000 hours. This cycling stresses materials through thermal expansion mismatches and wet-dry transitions.

Acceleration Factor | Chamber Setting | Equivalent Outdoor Exposure | Typical Application |

2.8x | 1.55 W/m² at 340nm | 1 year = 3 years outdoors | General durability screening |

5.5x | 1.55 W/m² + 70°C BPT | 6 months = 2.75 years | Rapid material comparison |

1.0x | 0.55 W/m² at 340nm | Real-time correlation | Validation of accelerated results |

Evaluating Mechanical and Electrical Performance Post-UV

Flexural Strength and Dimensional Stability Measurements

PCB substrates exposed to UV radiation exhibit reduced flexural modulus and increased brittleness. Three-point bend testing on post-exposure specimens from a UV resistance test chamber quantifies this degradation, with acceptable thresholds typically set at no more than 25% strength reduction. Dimensional measurements using coordinate measuring machines detect warpage or shrinkage that could affect component mounting or connector alignment.

Insulation Resistance and Dielectric Withstand Voltage

UV-induced microcracking and conformal coating breakdown compromise electrical insulation. Applying 500V DC megohm testing between adjacent traces reveals whether insulation resistance has degraded below acceptable limits (typically >100 MΩ). Dielectric withstand voltage testing at 1.5 times the operating voltage identifies incipient failure modes before they cause field failures.

Solder Joint Integrity and Interconnection Reliability

While UV primarily affects organic materials, the thermal cycling accompanying UV exposure stresses solder joints through coefficient of thermal expansion mismatches. Cross-sectional metallography and dye penetrant testing reveal crack propagation in solder fillets. Electrical continuity monitoring during accelerated testing can detect intermittent connection failures.

Predicting Lifespan of UV-Sensitive PCB Components

Correlation Studies with Natural Weathering Data

Establishing accurate lifetime predictions requires parallel exposure of control samples in outdoor weathering sites alongside chamber testing. Comparing degradation rates between Florida natural exposure (high UV and humidity) and chamber results creates correlation factors that convert accelerated test hours into real-world service years. These studies typically require 12-24 months to generate statistically valid data.

Arrhenius Modeling for Temperature-Dependent Failure Modes

Many UV degradation mechanisms follow Arrhenius temperature dependence, allowing mathematical modeling of failure rates at different temperatures. By testing identical PCB assemblies at three temperature levels (such as 50°C, 60°C, and 70°C black panel temperature) with constant irradiance, engineers calculate activation energies and extrapolate to actual operating temperatures.

Statistical Analysis and Confidence Intervals

Testing multiple specimens (typically 5-10 per condition) provides the statistical basis for lifetime predictions with quantified uncertainty. Weibull analysis of time-to-failure data yields characteristic life values and confidence bounds, supporting reliability engineering decisions about warranty periods and maintenance intervals.

Test Duration (Hours) | Equivalent Outdoor Years | Degradation Milestone |

500 | 1.5 years | Initial color shift detectable |

1000 | 3 years | 10% mechanical property reduction |

2000 | 6 years | Visible surface chalking, 25% property loss |

4000 | 12 years | Functional performance degradation threshold |

Material Aging Assessments Using LIB Industry's UV Resistance Test Chamber

Programmable Touch Screen Controller for Complex Protocols

The UV-SI-260 UV resistance test chamber features an Ethernet-connected programmable controller that stores multiple test sequences. Engineers can define multi-stage protocols incorporating varying irradiance levels, temperature setpoints, and moisture phases without manual intervention. Data logging capabilities record actual exposure conditions throughout the test, supporting regulatory compliance documentation and troubleshooting.

Sample Capacity and Mounting Flexibility

With accommodation for 56 specimens of 75x150mm size, the chamber supports statistically significant sample populations while maintaining the critical 50mm lamp-to-specimen distance. Both flat specimen holders for PCB coupons and 3D holders for assembled modules ensure proper exposure geometry. The removable sample shelf design facilitates periodic inspection without disrupting the test environment for remaining specimens.

Integrated Safety and Water Management Systems

Over-temperature, over-current, water shortage, earth leakage, and phase sequence protections prevent equipment damage and ensure operator safety during extended unattended operation. The automatic water supply system with integrated purification maintains consistent water quality for spray and condensation functions, eliminating a variable that could otherwise affect test repeatability. The SUS304 stainless steel interior resists corrosion despite constant moisture exposure.

Conclusion

UV resistance testing has evolved from optional validation to mandatory qualification for PCBs destined for challenging outdoor environments. The controlled acceleration, precise environmental control, and comprehensive data generation capabilities of modern test chambers enable engineers to confidently predict product performance across multi-year service lives. By integrating UV testing into the design verification process, manufacturers protect their quality reputation while meeting increasingly stringent regulatory requirements across automotive, aerospace, and consumer electronics sectors.

FAQs

What makes UV testing different from standard thermal cycling for PCBs?

UV testing specifically addresses photochemical degradation of organic materials like substrates, solder masks, and conformal coatings - failure modes that purely thermal testing cannot replicate. The combination of ultraviolet radiation, heat, and moisture simulates the synergistic effects that occur in actual outdoor service environments.

How long should PCBs be tested in a UV chamber for automotive qualification?

Automotive standards typically require 1000-2000 hours of cyclic exposure combining UV irradiation, condensation, and thermal cycling. The exact duration depends on the vehicle's intended market climate and component mounting location, with specifications defined in standards like SAE J2527 and manufacturer-specific protocols.

Can the same UV chamber test both rigid PCBs and flexible circuits?

Absolutely. The adjustable specimen holders accommodate both rigid FR-4 boards and flexible polyimide circuits. Testing protocols differ based on material properties - flexible circuits often require lower temperature exposure to prevent unrealistic stress from substrate stiffening, while maintaining equivalent UV irradiance levels for coating evaluation.

Partner with LIB Industry for Your PCB Testing Needs

As a leading UV resistance test chamber manufacturer and supplier, LIB Industry delivers complete turn-key environmental testing solutions - from initial design consultation through installation and operator training. Our UV-SI-260 chamber provides the precision, reliability, and documentation capabilities essential for electronics qualification programs. Contact our technical specialists at ellen@lib-industry.com to discuss how our environmental testing equipment supports your product development objectives.