UV Resistance Test Chamber Applications in Automotive Plastic Parts Testing

Several months after installing the Light Resistance Test Chamber, an experienced instrumentation professional from India shared his feedback:“We have installed and serviced weathering instruments for many years, including systems from leading European brands. After using the LIB Light Resistance Test Chamber, we found its performance and test reliability to be on par with ATLAS, while offering a more competitive price. The instrument quality fully meets our expectations, and we are very satisfied with its overall performance.”This feedback highlights the chamber's proven stability, consistent light exposure control, and strong value for long-term material testing applications.

Automotive plastic parts face relentless exposure to ultraviolet radiation throughout their service life, making UV resistance testing essential for quality assurance. A UV resistance test chamber enables manufacturers to simulate years of sunlight exposure within weeks, predicting how dashboard components, bumpers, exterior trim, and interior plastics will perform under real-world conditions. This accelerated weathering approach identifies potential failures - such as discoloration, cracking, or mechanical degradation - before parts reach production lines. By subjecting materials to controlled UV radiation, temperature cycles, and moisture conditions, automotive engineers can optimize material formulations, validate protective coatings, and ensure components meet stringent durability standards demanded by modern vehicle lifespans.

Why UV Resistance is Critical for Automotive Plastics?

Material Degradation Mechanisms

Ultraviolet radiation triggers photochemical reactions within polymer chains, breaking molecular bonds and initiating oxidative degradation. This photodegradation process weakens the structural integrity of automotive plastics, reducing their tensile strength and impact resistance over time. Polypropylene, ABS, polycarbonate, and other common automotive polymers exhibit varying susceptibility to UV-induced damage, necessitating material-specific testing protocols.

Economic Implications of UV Damage

Premature failure of plastic components generates substantial warranty costs and damages brand reputation. Dashboard cracking, faded exterior trim, and brittle weather stripping represent common UV-related failures that lead to customer dissatisfaction. Comprehensive UV testing during development phases prevents these expensive post-market failures while extending component service life beyond standard warranty periods.

Regulatory and Quality Standards

Automotive industry standards such as SAE J2527 and ISO 4892 establish UV exposure requirements for exterior and interior components. Manufacturers must demonstrate compliance through documented testing, providing validation that materials withstand specified radiation doses. UV resistance chambers deliver the controlled, repeatable conditions necessary to meet these certification requirements across global markets.

Effects of Sunlight and UV Exposure on Plastic ComponentsSpectral Damage Characteristics

Natural sunlight contains UV radiation spanning wavelengths from 290 to 400 nanometers, with UVA (315-400nm) and UVB (280-315nm) causing distinct degradation patterns. UVB radiation, though representing smaller solar proportions, delivers higher energy that accelerates surface oxidation and color changes. UVA penetrates deeper into materials, affecting bulk properties and causing long-term mechanical property deterioration that becomes evident through embrittlement and reduced flexibility.

distinct degradation patterns. UVB radiation, though representing smaller solar proportions, delivers higher energy that accelerates surface oxidation and color changes. UVA penetrates deeper into materials, affecting bulk properties and causing long-term mechanical property deterioration that becomes evident through embrittlement and reduced flexibility.

Visual and Aesthetic Deterioration

Color shift represents one of the most noticeable effects of UV exposure on automotive plastics, and its severity is typically evaluated using a UV resistance test chamber under controlled radiation conditions. Pigments undergo photochemical breakdown, causing fading or yellowing that particularly affects dark-colored components. Surface gloss reduction occurs as microscopic crazing develops, scattering reflected light and producing a chalky appearance. These aesthetic changes diminish vehicle appeal and perceived quality regardless of maintained structural performance.

Mechanical Property Changes

Prolonged UV exposure reduces elongation at break, making plastics increasingly brittle and prone to cracking under stress. Tensile strength typically decreases by 20-40% after extended weathering, compromising structural components' load-bearing capacity. Impact resistance deteriorates significantly, causing parts that once absorbed energy during collisions to shatter unexpectedly, raising safety concerns for both occupants and pedestrians.

Simulating Real-world UV Conditions in Test ChambersAccelerated Weathering Principles

Test chambers concentrate UV radiation beyond natural sunlight intensity, compressing years of exposure into manageable testing timeframes. The UV-SI-260 model delivers controlled irradiance from 0.3 to 20 W/m², enabling researchers to establish correlation factors between laboratory hours and outdoor exposure years. This acceleration maintains relevant degradation mechanisms while eliminating the impracticality of multi-year real-time testing.

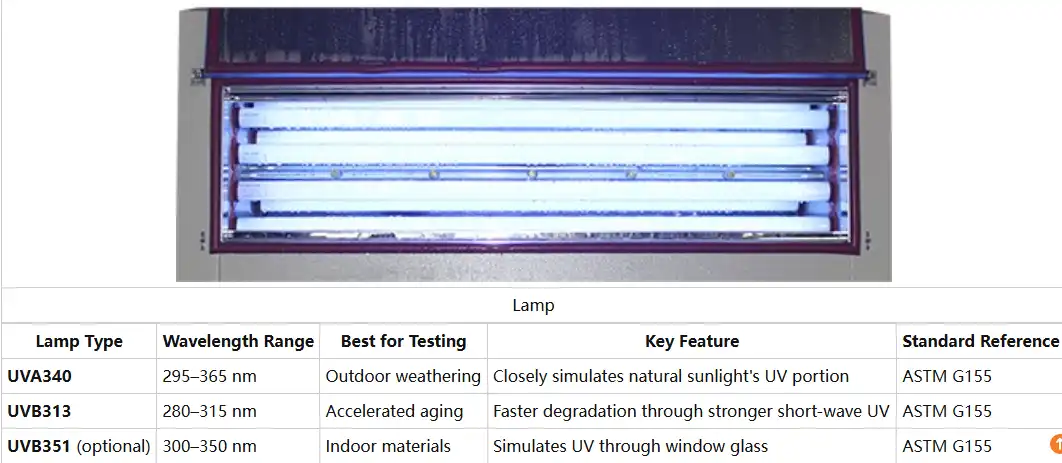

Lamp Selection and Spectral Matching

Fluorescent UV lamps provide either UVA-340 or UVB-313 spectral outputs, each simulating different environmental conditions. UVA-340 lamps replicate the critical short-wavelength portion of sunlight reaching Earth's surface, ideal for predicting outdoor durability. UVB-313 lamps deliver harsher, shorter-wavelength radiation for maximum acceleration, though this approach may produce degradation mechanisms not observed in actual service conditions.

Environmental Cycling Protocols

Realistic weathering involves more than continuous UV exposure. Chamber programs alternate between UV irradiation phases and dark condensation periods where elevated humidity attacks degraded surface layers. Temperature cycling between ambient and 90°C simulates day-night variations, while water spray systems replicate rainfall effects. These combined stresses reveal synergistic degradation that isolated testing misses.

Test Parameter | Range/Specification | Purpose |

UV Wavelength | 290-400nm (UVA-340 or UVB-313) | Matches solar UV spectrum |

Irradiance Control | 0.3-20 W/m² | Accelerates aging process |

Temperature Range | Ambient to 90°C ±2℃ | Simulates thermal cycling |

Humidity Control | ≥95% RH during condensation | Replicates moisture exposure |

Specimen Distance | 50mm from lamps | Ensures uniform irradiation |

Evaluating Mechanical and Color Stability of Automotive PlasticsTensile and Flexural Testing

Before-and-after mechanical testing quantifies UV exposure effects on load-bearing capacity. Tensile tests measure changes in ultimate strength, yield point, and elongation at break following UV resistance test chamber exposure. Flexural testing evaluates beam stiffness and failure modes under bending loads, revealing brittleness increases that threaten component functionality during normal vehicle operation and crash scenarios.

Colorimetric Analysis Methods

Spectrophotometers measure color changes using the CIELAB color space, where ΔE values quantify total color difference perception. Values below 1.0 indicate imperceptible changes, while ΔE exceeding 3.0 becomes noticeable to average observers. Automotive specifications typically require ΔE values under 2.0 after prescribed UV exposure, ensuring color consistency between adjacent components throughout vehicle life.

Surface Property Assessment

Gloss meters track surface shine degradation, with 60-degree gloss measurements providing standardized comparisons. Surface roughness profilers detect microscopic texture changes preceding visible deterioration. Fourier-transform infrared spectroscopy (FTIR) identifies chemical bond changes within surface layers, revealing oxidation products and degradation pathways before mechanical properties significantly decline, enabling predictive failure analysis.

Accelerated UV Aging Methods for Plastic PartsContinuous Exposure Protocols

Constant UV irradiation at elevated intensity provides the fastest screening method for material comparison. Sample panels mounted on chamber racks receive uniform exposure at the standardized 50mm distance, with eight 40-watt fluorescent lamps delivering consistent radiation across the test area. This approach suits preliminary material selection but may overlook temperature-humidity synergies affecting actual performance.

Cyclic Weathering Sequences

Automotive-relevant protocols alternate UV exposure with dark condensation phases, typically following SAE J2527 specifications. A common cycle includes eight hours of UVA-340 irradiation at 70°C black panel temperature, followed by four hours of condensation at 50°C with 100% relative humidity. These cycles repeat continuously for 500-2000 hours depending on application severity and performance requirements.

Water Spray Integration

Ten precision nozzles within the chamber deliver calibrated water spray during or between UV cycles, simulating rainfall and morning dew effects. The 0.5mm diameter nozzles produce fine droplets with controlled settlement rates of 0.8-1.0mm per 80cm² hourly. Water spray enhances degradation through thermal shock, physical erosion of weathered surfaces, and accelerated leaching of additives from near-surface regions.

Aging Method | Typical Duration | Best Application |

Continuous UV Exposure | 500-1000 hours | Material screening and comparison |

Cyclic UV/Condensation | 1000-2000 hours | Predicting outdoor durability |

UV with Water Spray | 1500-3000 hours | Exterior components with rain exposure |

Predicting Long-term Durability of Automotive ComponentsCorrelation with Outdoor Weathering

Establishing relationships between chamber hours and outdoor years requires parallel exposure studies. Florida and Arizona weathering stations provide one-year reference data, while UV resistance test chamber testing compresses equivalent exposure into weeks. Correlation factors typically range from 3:1 to 8:1 depending on material, climate region, and chamber protocol, enabling manufacturers to predict five-year or ten-year performance from abbreviated laboratory testing.

Service Life Modeling Approaches

Mathematical models incorporate UV dose, temperature, and humidity data to predict time-to-failure for specific degradation modes. Arrhenius relationships describe temperature-acceleration factors, while reciprocity law principles relate radiation intensity to exposure duration. Advanced models account for non-linear degradation kinetics observed in many polymers, where initial UV exposure causes minimal change before accelerated deterioration begins.

Quality Control and Batch Verification

Production material lots undergo routine UV screening to verify consistency with qualified materials. Pass-fail criteria based on retained mechanical properties or color stability limits ensure only conforming materials enter manufacturing. Chamber testing frequency depends on supplier reliability and component criticality, ranging from every batch for safety-related parts to quarterly verification for established materials.

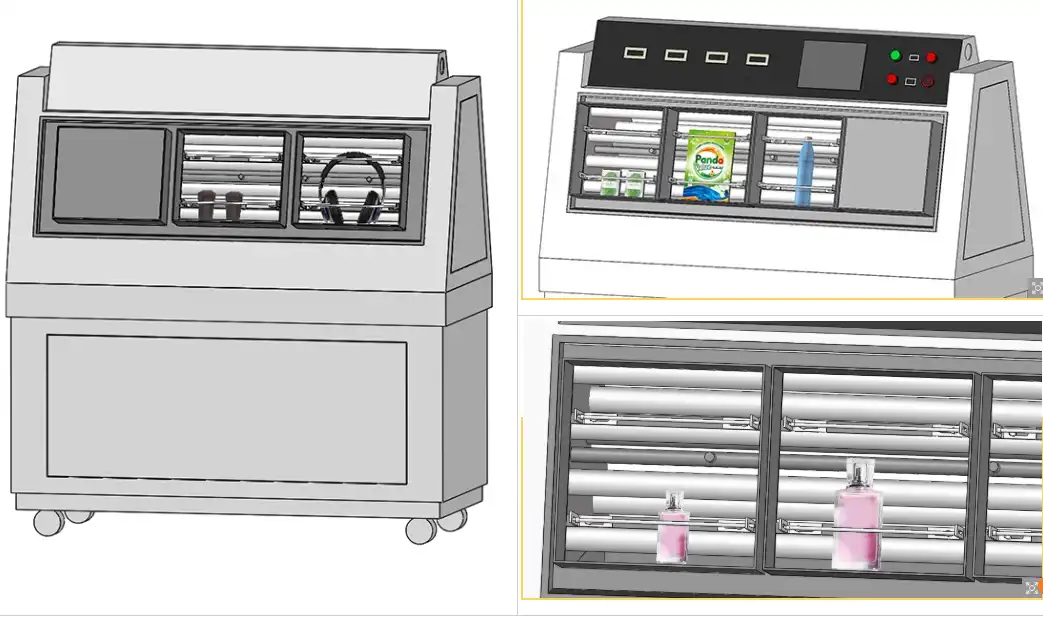

LIB Industry's UV Resistance Test Chamber for Reliable Temperature & Humidity ControlAdvanced Control Systems

The UV-SI-260 model features a programmable color LCD touchscreen controller with Ethernet connectivity, enabling remote monitoring and data logging throughout extended test programs. Users configure complex cycling sequences through intuitive interfaces, storing multiple protocols for different material types or industry standards. Real-time graphical displays track irradiance, temperature, and humidity parameters, alerting operators to deviations requiring attention.

logging throughout extended test programs. Users configure complex cycling sequences through intuitive interfaces, storing multiple protocols for different material types or industry standards. Real-time graphical displays track irradiance, temperature, and humidity parameters, alerting operators to deviations requiring attention.

Precision Environmental Management

Maintaining black panel temperatures between 35-80°C ensures thermal conditions match specified protocols, with ±2°C accuracy across the entire specimen plane. Automatic water supply systems and integrated purification equipment eliminate testing interruptions while preventing contamination effects on sensitive materials. The chamber achieves ≥95% relative humidity during condensation phases through precise temperature-dewpoint control.

Safety and Reliability Features

Comprehensive protection systems include over-temperature shutoff, over-current breakers, water shortage detection, earth leakage protection, and phase sequence monitoring. These redundant safeguards prevent equipment damage and ensure operator safety during unattended overnight or weekend operation. The SUS304 stainless steel interior resists corrosion from moisture and chemical emissions, maintaining chamber integrity throughout years of continuous service.

Control Feature | Specification | Benefit |

Temperature Control | Ambient to 90°C ±2℃ | Precise thermal simulation |

Humidity Range | ≥95% RH | Realistic condensation conditions |

Irradiance Control | 0.3-20 W/m² | Adjustable acceleration rates |

Programmable Cycles | 1-9999 hours, 59 minutes | Flexible test protocols |

Sample Capacity | 56 pieces (75×150mm) | High-throughput testing |

Conclusion

UV resistance testing stands as a non-negotiable requirement for automotive plastic component validation, protecting manufacturers from costly failures while ensuring vehicles maintain aesthetic appeal and structural integrity throughout their service lives. Modern UV resistance test chambers deliver precisely controlled accelerated weathering that predicts years of outdoor exposure within practical development timeframes. By implementing comprehensive UV evaluation programs using equipment like the UV-SI-260, automotive engineers make informed material selections, optimize protective treatments, and validate component designs against demanding industry standards.

FAQWhat duration of UV chamber testing equals one year of outdoor exposure?

The correlation varies by material and climate, typically ranging from 500-1500 chamber hours equaling one outdoor year. Florida subtropical conditions require different correlation factors than Arizona desert environments, while polymer chemistry significantly affects degradation rates under accelerated testing.

Can UV resistance chambers test assembled components or only flat samples?

Chambers accommodate both approaches. The UV-SI-260 provides flat specimen holders for standardized material coupons plus 3D holders for testing assembled parts like mirror housings, bumper sections, or complete dashboard assemblies, revealing stress-concentration effects not evident in flat-sample testing.

How do UVA-340 and UVB-313 lamps differ in automotive testing applications?

UVA-340 lamps replicate the critical short-wavelength portion of natural sunlight, providing realistic outdoor weathering simulation. UVB-313 lamps deliver more aggressive shorter wavelengths for maximum acceleration but may produce degradation mechanisms not observed in actual vehicle service, making them better suited for quality control screening.

What maintenance requirements ensure accurate UV chamber performance?

Lamp replacement follows manufacturer-specified intervals based on operating hours, typically 1000-2000 hours depending on intensity settings. Irradiance sensors require annual calibration, while water system filters need quarterly replacement. Regular cleaning of interior surfaces prevents contamination effects on sensitive test specimens.

LIB Industry, a leading UV resistance test chamber manufacturer and supplier, specializes in turn-key environmental testing solutions tailored to automotive applications. Contact our technical team at ellen@lib-industry.com to discuss your specific UV testing requirements and explore how our advanced chamber technology can strengthen your quality assurance programs.