Printed circuit boards (PCBs) used in outdoor electronics, automotive systems, and aerospace applications are routinely subjected to ultraviolet exposure, which can significantly accelerate material degradation and affect long-term performance. UV resistance test chambers allow manufacturers to recreate combined UV radiation, temperature, and humidity conditions within a controlled laboratory environment. This enables engineers to assess the durability of PCB base materials, solder masks, and protective surface coatings before products are released to the market.

The chamber's performance has been validated through practical use, as reflected in post-installation customer feedback stating that the system operates smoothly and reliably in daily testing. This proven stability makes the UV resistance test chamber a key component in PCB qualification processes, providing consistent and repeatable results while supporting efficient accelerated aging studies and compliance with industry testing standards.

Understanding UV resistance testing standards is crucial when evaluating material durability under ultraviolet exposure. ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) provide comprehensive frameworks that define testing methodologies, equipment specifications, and result interpretation protocols. These standards ensure consistency across laboratories worldwide, enabling manufacturers to validate product performance against recognized benchmarks using a UV resistance test chamber. Both organizations address critical aspects including light source specifications, exposure cycles, temperature control, and sample preparation requirements. Adhering to these standards guarantees reliable data for product development, quality assurance, and regulatory compliance across diverse industries.

What Are the Key ASTM Standards for UV Testing?

ASTM G154: Standard Practice for Operating Fluorescent Ultraviolet Lamp Apparatus

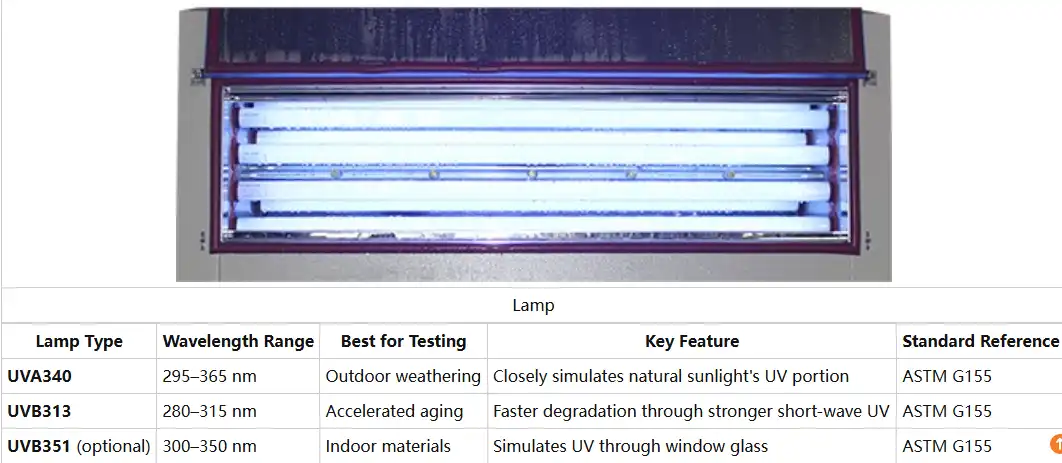

ASTM G154 establishes procedures for exposing non-metallic materials to fluorescent UV lamps combined with moisture. This standard specifies lamp types - primarily UVA-340 and UVB-313 - that replicate different solar radiation wavelengths. UVA-340 lamps simulate sunlight in the critical short-wave UV region, while UVB-313 lamps provide accelerated degradation for comparative testing. The standard defines exposure cycles alternating between UV irradiation and condensation phases.

UVA-340 and UVB-313 - that replicate different solar radiation wavelengths. UVA-340 lamps simulate sunlight in the critical short-wave UV region, while UVB-313 lamps provide accelerated degradation for comparative testing. The standard defines exposure cycles alternating between UV irradiation and condensation phases.

Irradiance levels must be monitored continuously using calibrated radiometers positioned at specimen height. ASTM G154 mandates black panel temperature measurements to correlate laboratory conditions with outdoor weathering. The standard requires documentation of lamp age, irradiance uniformity across the exposure area, and chamber temperature profiles. Specimen positioning follows strict guidelines ensuring uniform exposure while maintaining the 50mm distance from lamp surfaces.

ASTM D4329: Standard Practice for Fluorescent UV Exposure of Plastics

ASTM D4329 specifically addresses plastic materials, providing detailed protocols for evaluating color change, gloss retention, cracking, and chalking. This standard recognizes that different polymer families exhibit unique degradation mechanisms under UV exposure. Testing procedures accommodate various specimen geometries and mounting configurations. The practice emphasizes reproducibility through precise control of irradiance intensity, typically ranging from 0.3 to 20 W/m² within the 290-400nm bandwidth.

Temperature cycling protocols outlined in D4329 simulate diurnal variations experienced outdoors. The standard permits customized exposure schedules tailored to specific geographic conditions or end-use environments. Evaluation intervals are strategically planned to capture progressive degradation patterns without compromising statistical validity.

ASTM D4587: Standard Practice for Fluorescent UV-Condensation Exposures

ASTM D4587 focuses on combined UV radiation and moisture exposure through condensation mechanisms rather than water spray. This approach replicates dew formation occurring during nighttime outdoor conditions. Specimens undergo alternating cycles of UV exposure at elevated temperatures followed by condensation phases in darkness. The standard specifies chamber design requirements ensuring uniform vapor distribution and condensation rates across test surfaces.

Black panel temperature control during UV phases typically maintains 60-70°C, while condensation cycles operate at 45-50°C with humidity levels exceeding 95% RH. ASTM D4587 provides correlation data linking laboratory exposure hours to equivalent outdoor weathering duration, though these relationships vary by material type and geographic location.

Overview of ISO Guidelines for UV Resistance

ISO 4892-3: Methods of Exposure to Laboratory Light Sources

ISO 4892-3 presents comprehensive guidance for fluorescent UV lamp testing, harmonizing with but not duplicating ASTM approaches, and is widely implemented using a UV resistance test chamber. This standard emphasizes international consensus on equipment specifications, calibration procedures, and reporting requirements. ISO 4892-3 defines three exposure methods: Method A uses UVA-340 lamps with water spray, Method B employs UVA-351 lamps with condensation, and Method C utilizes UVB-313 lamps for accelerated testing.

UV resistance test chamber. This standard emphasizes international consensus on equipment specifications, calibration procedures, and reporting requirements. ISO 4892-3 defines three exposure methods: Method A uses UVA-340 lamps with water spray, Method B employs UVA-351 lamps with condensation, and Method C utilizes UVB-313 lamps for accelerated testing.

The standard mandates regular spectral distribution verification ensuring lamp output remains within acceptable tolerances throughout their service life. ISO 4892-3 requires temperature monitoring at multiple points including black standard temperature, white standard temperature, and chamber air temperature. These measurements provide comprehensive thermal characterization of the testing environment.

ISO 11507: Paints and Varnishes Exposure to Artificial Weathering

ISO 11507 specifically targets coating materials, establishing performance criteria for protective and decorative finishes. This guideline prescribes standardized cycles alternating UV exposure with moisture condensation. Typical cycles include 8 hours of UV irradiation at 60°C black panel temperature followed by 4 hours of condensation at 50°C. The standard permits variations to accommodate specific product requirements or accelerated testing objectives.

Specimen preparation receives detailed attention in ISO 11507, covering substrate selection, application techniques, curing conditions, and film thickness verification. The standard mandates parallel testing of reference materials with known weathering characteristics, enabling relative performance assessment and data validation across different laboratories.

ISO 16474: Paints and Varnishes Methods of Exposure to Laboratory Light Sources

ISO 16474 represents an updated framework superseding earlier standards while maintaining continuity with established practices. Part 3 of this multi-part standard addresses fluorescent UV lamps specifically. The document emphasizes risk-based testing approaches where exposure conditions match anticipated service environments. ISO 16474 introduces refined terminology distinguishing between irradiance, radiant exposure, and spectral power distribution.

Calibration requirements are stringent, specifying annual verification of radiometric sensors against traceable standards. The guideline recognizes technological advances in UV lamp manufacturing and monitoring systems, accommodating newer equipment while maintaining compatibility with legacy testing protocols.

Test Chamber Requirements for Standard Compliance

Environmental Control Specifications

Compliant UV resistance test chambers must demonstrate precise environmental parameter control throughout the exposure volume. Temperature uniformity across specimen planes should not exceed ±2°C variation, while irradiance uniformity must remain within ±10% across the central exposure area. The UV-SI-260 chamber employs eight 40W fluorescent UV lamps arranged to minimize shadowing and ensure consistent energy distribution. Programmable color LCD touch screen controllers enable complex exposure schedules with multiple segments.

Humidity control systems maintain ≥95% RH during condensation or water spray cycles. Automatic water supply systems with integrated purification ensure consistent water quality preventing mineral deposits on specimens. Chamber construction using SUS304 stainless steel interiors resists corrosion while facilitating cleaning and maintenance. Steel plate exteriors with protective coatings provide structural integrity and thermal insulation.

Safety and Monitoring Systems

Standards compliance mandates comprehensive safety interlocks protecting operators and maintaining test integrity. Over-temperature protection prevents chamber excursions beyond safe operating limits. Over-current protection safeguards electrical systems during lamp startup or component failures. Water shortage protection halts operation when condensation or spray systems cannot function properly. Earth leakage protection and phase sequence protection address electrical hazards.

Real-time monitoring systems track irradiance levels, black panel temperature, chamber temperature, and humidity continuously. Ethernet connectivity enables remote monitoring and data logging for extended unattended operation. Automated alerts notify operators of deviations from programmed parameters, allowing prompt corrective action before test validity is compromised.

Specimen Holding and Positioning

Standard-compliant UV resistance test chambers provide versatile specimen mounting accommodating flat samples and three-dimensional components. The UV-SI-260 chamber accepts 56 pieces of 75×150mm specimens in removable holders enabling efficient sample exchange. Positioning mechanisms maintain the critical 50mm distance between specimen surfaces and lamp envelopes, optimizing UV dose delivery while preventing thermal damage.

Adjustable mounting angles allow testing at various orientations relevant to actual service conditions. Specimen holders resist UV degradation and temperature cycling without contributing contaminants that might interfere with test results. Easy lamp replacement facilitates maintenance and ensures consistent spectral output throughout testing programs.

Accelerated Testing Methods Defined by ASTM and ISO

Irradiance Intensification Strategies

Accelerated weathering increases irradiance levels beyond typical solar intensities, compressing years of outdoor exposure into weeks or months of laboratory testing. UVB-313 lamps deliver approximately four times the short-wavelength UV energy of natural sunlight, dramatically accelerating degradation mechanisms. However, this acceleration may alter failure modes compared to natural weathering, requiring careful correlation studies.

Standards specify acceptable irradiance ranges balancing acceleration against test validity. The 0.3-20 W/m² control range provided by compliant chambers allows customization based on material sensitivity and testing objectives. Higher irradiance settings suit preliminary screening while moderate levels support correlation with outdoor exposure. Continuous irradiance monitoring compensates for lamp aging, maintaining consistent exposure throughout test duration.

Temperature and Moisture Cycling Protocols

Synergistic effects between UV radiation, temperature, and moisture often govern material degradation rates. Standards define cycling protocols replicating diurnal patterns: UV exposure during simulated daylight hours at elevated temperatures followed by dark condensation or water spray cycles mimicking nighttime dew formation. The UV-SI-260 chamber's ambient to 90°C temperature range accommodates diverse protocols.

Black panel temperature measurement provides direct assessment of specimen surface heating under irradiation. BPT control between 35-80°C enables testing under conditions ranging from temperate climates to extreme desert environments. Water spray cycles with adjustable duration from 1 to 9999 hours and 59 minutes permit extended exposure studies without frequent operator intervention.

Correlation Factors and Outdoor Equivalence

Establishing correlation between accelerated laboratory testing and natural outdoor weathering remains challenging due to geographic variability, seasonal fluctuations, and material-specific responses. Standards recommend parallel exposure programs placing identical specimens in outdoor weathering stations alongside laboratory testing. Statistical analysis of degradation rates generates correlation factors specific to material-location combinations.

Typical correlation ratios range from 5:1 to 20:1 depending on acceleration intensity and degradation mechanism. Photochemical processes may correlate well with laboratory testing while hydrolytic degradation shows greater discrepancies. Standards emphasize that accelerated testing identifies relative durability rankings rather than absolute service life predictions. Validation against field performance data strengthens confidence in laboratory results.

Testing Parameter | ASTM G154 | ASTM D4329 | ISO 4892-3 |

Primary Lamp Type | UVA-340, UVB-313 | UVA-340, UVB-313 | UVA-340, UVA-351, UVB-313 |

Irradiance Range | 0.35-1.55 W/m² @ 340nm | 0.45-1.35 W/m² @ 340nm | 0.51-0.83 W/m² @ 340nm |

Black Panel Temperature | 60°C or 70°C | 60°C or 70°C | 65°C ± 3°C |

Moisture Method | Condensation or Spray | Condensation | Condensation or Spray |

Typical Cycle | 8h UV / 4h condensation | 8h UV / 4h condensation | 8h UV / 4h condensation |

Interpreting UV Test Results for Product Validation

Visual Assessment and Measurement Techniques

Visual evaluation captures color change, gloss loss, cracking, crazing, chalking, and surface erosion. Standardized scales quantify subjective observations, enabling consistent reporting across laboratories and evaluators. Instrumental color measurement using spectrophotometers provides objective quantification through Lab color space parameters. Delta E calculations summarize total color difference, with values above 3-5 units typically representing noticeable visual changes.

Gloss meters measure specular reflection at standardized angles (20°, 60°, or 85° depending on initial gloss level). Percentage gloss retention tracks surface degradation affecting appearance and protective properties. Microscopic examination reveals microstructural changes including surface roughening, crack networks, and phase separation invisible to unaided observation. Digital image analysis automates crack density and distribution measurements.

Mechanical Property Degradation Assessment

UV exposure often compromises mechanical properties before visible damage appears. After conditioning samples in a UV resistance test chamber, tensile testing on exposed specimens quantifies strength and elongation retention. Plastic materials may exhibit embrittlement indicated by reduced elongation at break despite maintained tensile strength. Impact resistance testing further reveals increased brittleness, affecting damage tolerance in service applications.

Flexural testing assesses stiffness changes relevant to structural components. Hardness measurements detect surface layer degradation or crosslinking. Standards recommend testing unexposed control specimens alongside weathered samples, calculating property retention percentages. Statistical analysis determines whether observed changes exceed normal test variability, establishing significance thresholds.

Chemical and Physical Analysis Methods

Fourier-transform infrared spectroscopy (FTIR) identifies chemical changes including oxidation, chain scission, and crosslinking. Carbonyl index calculations track oxidative degradation progress. Differential scanning calorimetry (DSC) measures crystallinity changes affecting mechanical properties and chemical resistance. Thermogravimetric analysis (TGA) quantifies mass loss from volatile component evolution during weathering.

Surface analysis techniques including scanning electron microscopy (SEM) visualize topographical changes at microscopic scales. Energy-dispersive X-ray spectroscopy (EDS) maps elemental distribution revealing additive migration or loss. These advanced characterization methods complement standard visual and mechanical assessments, providing deeper understanding of degradation mechanisms guiding material improvement strategies.

Property | Measurement Method | Acceptance Criteria | Test Frequency |

Color Change | Spectrophotometry (ΔE) | ΔE < 5 units | Every 250 hours |

Gloss Retention | Gloss meter @ 60° | > 80% initial value | Every 250 hours |

Tensile Strength | ASTM D638 | > 75% initial value | Every 500 hours |

Surface Cracking | Visual inspection (scale 0-5) | Rating < 3 | Every 250 hours |

Yellowing Index | ASTM E313 | ΔYI < 10 units | Every 250 hours |

Ensuring Global Compliance in UV Resistance Evaluation

Regional Standard Variations and Harmonization

While ASTM and ISO standards share common technical foundations, regional preferences and regulatory requirements create testing variations. North American markets typically reference ASTM standards while European manufacturers align with ISO guidelines. Asian markets increasingly adopt ISO frameworks though domestic standards persist in specific industries. Successful global product launches require understanding these nuances and conducting appropriate validation testing.

Harmonization efforts aim to reduce duplicate testing burdens through mutual recognition agreements. Testing laboratories accredited to ISO/IEC 17025 demonstrate technical competence regardless of standard preference. Comprehensive test reports documenting all exposure parameters enable assessment against multiple standard criteria from single test programs. Strategic testing plans identify critical requirements across target markets, optimizing resource allocation.

Documentation and Traceability Requirements

Standards compliance demands meticulous documentation establishing test validity and result traceability. Test reports must specify standard version, exposure method designation, lamp type and age, irradiance levels, temperature profiles, and complete exposure history. Specimen identification links results to specific material batches enabling lot-to-lot variability assessment. Calibration records verify measurement accuracy at time of testing.

Equipment maintenance logs demonstrate proper chamber operation and preventive maintenance compliance. Radiometer calibration certificates traceable to national standards institutes provide measurement assurance. Standard reference materials with known weathering characteristics validate testing procedures. Digital data acquisition systems with timestamp authentication prevent manipulation while facilitating regulatory audits.

Third-Party Certification and Laboratory Accreditation

Independent testing laboratories offer objective validation eliminating potential conflicts of interest in manufacturer self-testing. Laboratory accreditation to ISO/IEC 17025 provides confidence in technical competence, measurement accuracy, and result reliability. Accreditation bodies conduct rigorous assessments of quality management systems, personnel qualifications, equipment capabilities, and measurement uncertainties.

Certification marks from recognized standards organizations communicate compliance to customers, regulators, and supply chain partners. Product certifications may require periodic testing demonstrating ongoing compliance as materials or processes change. Strategic partnerships with accredited laboratories streamline certification processes while maintaining technical independence essential for market acceptance.

Temperature Performance Testing with LIB Industry's UV Resistance Test Chamber

Advanced Temperature Control Capabilities

The UV-SI-260 UV resistance test chamber's ambient to 90°C temperature range with ±2°C precision enables comprehensive thermal performance validation alongside UV exposure testing. Independent temperature control during UV irradiation and dark cycles permits simulation of extreme diurnal variations. Black panel temperature monitoring from 35-80°C provides direct measurement of specimen surface conditions critical for accurate weathering simulation.

UV exposure testing. Independent temperature control during UV irradiation and dark cycles permits simulation of extreme diurnal variations. Black panel temperature monitoring from 35-80°C provides direct measurement of specimen surface conditions critical for accurate weathering simulation.

Programmable temperature profiles accommodate complex testing protocols including gradual ramps simulating sunrise/sunset transitions, sustained peak exposures replicating midday conditions, and rapid changes testing thermal shock resistance. Thermal uniformity across the 450×1170×500mm internal chamber volume ensures consistent specimen treatment regardless of positioning. SUS304 stainless steel construction provides excellent thermal conductivity minimizing temperature gradients.

Integrated Environmental Stress Testing

Combined UV, temperature, and humidity exposure reveals synergistic degradation mechanisms undetectable in single-factor testing. The UV-SI-260's humidity control maintaining ≥95% RH during moisture cycles enables hygrothermal stress evaluation. Water spray systems with ten 0.5mm diameter nozzles delivering controlled deposition rates simulate rain exposure. Sequential exposure cycles alternating UV irradiation, elevated temperature, moisture condensation, and water spray replicate complex outdoor weathering sequences.

Material responses to environmental stress combinations often deviate from predictions based on individual factor testing. Polymer matrix swelling from moisture absorption accelerates UV penetration and oxidation. Thermal cycling induces microcracking providing pathways for moisture ingress. Standards-compliant integrated testing conducted in chambers like the UV-SI-260 provides realistic performance data supporting confident product launches.

Quality Assurance Through Comprehensive Testing

LIB Industry's UV resistance test chambers enable complete characterization programs from initial material screening through final product validation. Standardized testing protocols ensure reproducibility across research, development, quality control, and certification applications. Ethernet connectivity facilitates data integration with laboratory information management systems (LIMS) supporting statistical process control and trend analysis.

Programmable color LCD touch screen controllers simplify complex test protocol implementation while maintaining precise parameter control. Automatic water supply systems with purification eliminate operator intervention reducing contamination risks. Comprehensive safety systems including over-temperature protection, over-current protection, water shortage protection, earth leakage protection, and phase sequence protection ensure safe unattended operation during extended exposure studies.

Chamber Component | UV-SI-260 Specification | Standard Requirement | Compliance Status |

Internal Dimensions | 450×1170×500mm | Minimum 400mm specimen distance | Exceeds minimum |

Temperature Range | Ambient ~ 90°C ±2°C | ±3°C uniformity maximum | Superior precision |

Irradiance Control | 0.3-20 W/m² @ 290-400nm | 0.3-2.0 W/m² @ 340nm | Exceeds range |

BPT Range | 35-80°C | 50-70°C typical | Extended capability |

Lamp-Specimen Distance | 50mm | 50±2mm | Exact compliance |

Specimen Capacity | 56 pieces (75×150mm) | Minimum 12 pieces | Expanded capacity |

Conclusion

UV resistance testing standards from ASTM and ISO provide essential frameworks ensuring reliable material performance evaluation. Compliance requires precision equipment like LIB Industry's UV-SI-260 chamber delivering controlled UV exposure, temperature cycling, and moisture conditions. Understanding standard requirements, accelerated testing principles, and result interpretation enables confident product validation. Global compliance demands awareness of regional preferences while maintaining fundamental technical rigor. Temperature performance integration enhances testing comprehensiveness, revealing synergistic degradation mechanisms critical for accurate durability predictions.

FAQs

What is the typical duration for UV resistance testing according to ASTM and ISO standards?

Testing duration varies based on material type and performance requirements, ranging from 500 hours for preliminary screening to 2000+ hours for comprehensive validation. Standards recommend exposure intervals of 250-500 hours for periodic assessment, with total duration determined by correlation studies linking laboratory exposure to anticipated service life.

How do UVA-340 and UVB-313 lamps differ in accelerated weathering applications?

UVA-340 lamps accurately simulate solar UV spectral distribution in the critical short-wavelength region, providing realistic weathering patterns. UVB-313 lamps deliver intensified short-wavelength radiation producing faster degradation suitable for comparative testing, though they may alter failure mechanisms compared to natural exposure requiring careful correlation validation.

Can UV resistance test results from one standard be directly compared to another standard?

Direct comparison requires careful consideration of exposure parameter differences between standards. While fundamental degradation mechanisms remain consistent, variations in irradiance levels, temperature cycling, and moisture methods affect degradation rates. Comprehensive test reports documenting all parameters enable cross-standard assessment, though parallel testing under multiple standards provides highest confidence.

Contact LIB Industry for UV Testing Solutions

LIB Industry, a leading UV resistance test chamber manufacturer and supplier, delivers turn-key environmental testing solutions worldwide. Our expertise encompasses equipment design, installation, training, and ongoing technical support. For detailed specifications, application guidance, or custom testing solutions, contact our team at ellen@lib-industry.com.