What is the difference between a UV Weatherometer and a Xenon Weatherometer?

Weatherometers are essential for simulating and speeding up the effects of weathering on different materials in the field of environmental testing. Xenon and UV weather meters are two of the most widely used kinds of weather meters. Despite having comparable functions, they differ in their features and uses. With an emphasis on UVA313 UVB340 UV Weatherometer, this article will examine the distinctions between these two varieties of weatherometers.

Understanding UV Weatherometers

Principles of UV Weatherometers

With a primary focus on the UV spectrum that causes weathering, UV weatherometers are specialized instruments that use ultraviolet (UV) lamps to simulate the effects of sunlight on materials. To replicate sun exposure, these devices frequently use fluorescent lamps that emit UV light in particular wavelength ranges, such as UVA (315-400 nm) and UVB (280-315 nm). UVA313 UVB340 UV Weatherometer assists manufacturers in evaluating how materials react to UV degradation by simulating these wavelengths, offering information about the materials' long-term durability and performance under actual conditions.

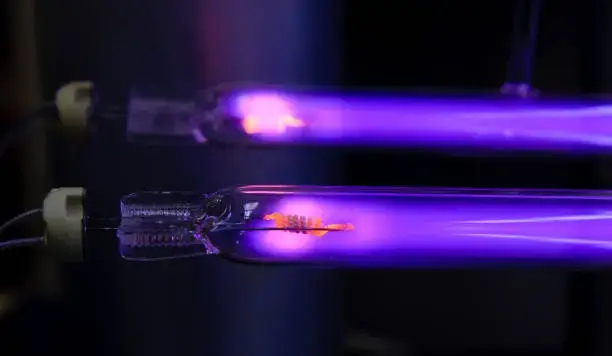

Types of UV Lamps: UVA313 and UVB340

UVA313 and UVB340 are two popular varieties of UV lamps used in weatherometers. Radiation from UVA313 lamps is mostly in the UVA spectrum, peaking at 313 nm. These lamps are frequently used to mimic weathering conditions outside. In contrast, UVB340 lamps produce light that is more closely aligned with the UV spectrum of the sun, with a peak emission at 340 nm. The particular testing requirements and the material under evaluation will determine which of UVA313 and UVB340 is best.

Applications of UV Weatherometers

UVA313 UVB340 UV Weatherometer is a vital instrument in many different industries, such as textiles, construction, and automobiles. These tools are especially helpful for testing materials that are extremely vulnerable to UV light, such as fabrics, coatings, and plastics. UV Weatherometers mimic the effects of prolonged sun exposure by subjecting materials to controlled UV light. This allows manufacturers to anticipate problems such as color fading, surface degradation, and changes in mechanical properties. This helps maximize product performance and durability by making sure that materials can handle the difficulties that UV exposure presents in practical applications.

Exploring Xenon Weatherometers

Principles of Xenon Weatherometers

Xenon arc lamps are used in xenon weatherometers to replicate the UV, visible, and infrared components of sunlight. Compared to UV weatherometers, these gadgets are meant to give a more accurate picture of natural sunlight. The continuous spectrum produced by xenon arc lamps closely resembles the spectral power distribution of sunlight.

Spectral Output of Xenon Lamps

The spectral output of xenon lamps covers a broader range of wavelengths compared to UV lamps. This includes not only the UV region but also visible and near-infrared radiation. The ability to simulate a full spectrum of sunlight allows Xenon Weatherometers to provide a more realistic representation of outdoor weathering conditions.

Applications of Xenon Weatherometers

Xenon Weatherometers are commonly used in industries where a full spectrum of sunlight is crucial for accurate weathering simulations. These include automotive interiors, aerospace materials, and high-performance coatings. Xenon Weatherometers are particularly effective for evaluating color change, gloss retention, and overall material degradation under realistic sunlight conditions.

Comparing UV and Xenon Weatherometers

Spectral Differences

Spectral output is the main distinction between xenon and UV weatherometers. UV weatherometers, like those that use UVA313 or UVB340 lamps, mimic the sun's ultraviolet rays by focusing on the UV region of the spectrum. However, Xenon weatherometers provide a wider spectrum that closely resembles natural sunlight by simulating visible light, infrared, and UV radiation. Because materials may react differently to each type of radiation, this variation in spectral composition can lead to different testing results and affect the precision of long-term durability evaluations.

Test Accuracy and Correlation

Although the goal of both kinds of weatherometers is to forecast outdoor weathering performance, there may be differences in how well they correlate with actual outcomes. UVA313 UVB340 UV Weatherometers might not fully capture the effects of visible and infrared radiation, but they might speed up results for materials that are sensitive to UV light. Because of their broader spectrum, xenon weatherometers frequently provide a better correlation with outdoor exposure to a greater variety of materials. However, the particular material and testing needs will determine whether to use a UV or Xenon weather meter.

Cost and Maintenance Considerations

Because UV lamps are typically less expensive and last longer than Xenon arc lamps, UV weatherometers are usually more cost-effective both initially and over time. Although they can be used for many common testing applications, Xenon Weatherometers can produce more thorough and detailed results, particularly for simulations that require a wider range of light. For some industries, their higher cost can be justified by their increased capability. Furthermore, Xenon weatherometers typically require more frequent calibration and lamp replacements, which increases maintenance requirements.

Conclusion

The materials being tested, the particular weathering effects of interest, and the intended correlation with outdoor exposure are some of the factors that determine whether to use a UV weather meter or a Xenon weather meter. UV weatherometers, especially those that use UVA313 or UVB340 lamps, are excellent at assessing UV-induced deterioration and provide affordable options for a variety of uses. Because xenon weatherometers simulate sunlight more thoroughly, they can be used with materials that are sensitive to a wider range of radiation. To choose the best weather meter for your testing requirements and guarantee precise predictions of material performance in actual settings, it is essential to comprehend these variations.

Contact Us

For expert guidance on selecting the right UVA313 UVB340 UV Weatherometer for your environmental testing needs, contact LIB Industry. Our team of specialists can provide tailored solutions to meet your specific requirements. Reach out to us at info@libtestchamber.com to learn more about our comprehensive range of environmental testing equipment and services.

References

1. ASTM G154-16: Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials

2. ISO 4892-3:2016: Plastics — Methods of exposure to laboratory light sources — Part 3: Fluorescent UV lamps

3. ASTM G155-13: Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

4. Wypych, G. (2018). Handbook of Material Weathering (6th Edition). ChemTec Publishing.

5. Pickett, J.E. (2018). Service Life Prediction of Polymers and Plastics Exposed to Outdoor Weathering. William Andrew Publishing.

6. Grossman, G.W. (1977). Correlation of laboratory to natural weathering. Journal of Coatings Technology, 49(633), 45-54.