Dust Proof Test Chamber Applications in EV Electrical System Testing

Electric vehicles depend on sophisticated electrical architectures that must withstand challenging environmental conditions throughout their operational lifespan. Dust intrusion poses significant threats to battery management systems, inverters, charging ports, and control modules. A dust proof test chamber enables manufacturers to simulate real-world particulate exposure scenarios, validating whether protective housings maintain IP ratings under extreme conditions. By subjecting high-voltage components to controlled dust concentrations (2-4kg/m³), engineers identify potential vulnerabilities in sealing mechanisms, gasket performance, and connector interfaces before vehicles reach consumers. This proactive validation approach reduces warranty claims, enhances safety certifications, and ensures long-term reliability in diverse operating environments.

Why EV Systems Require Dust Resistance Validation?Complex Electrical Architectures Demand Protection

Modern electric vehicles integrate hundreds of interconnected electrical components operating at voltages exceeding 800V. These systems include battery packs with thousands of individual cells, power distribution units managing kilowatt-level loads, and thermal management circuits maintaining optimal operating temperatures. Each connection point, junction box, and cable gland represents a potential entry path for airborne particulates.

battery packs with thousands of individual cells, power distribution units managing kilowatt-level loads, and thermal management circuits maintaining optimal operating temperatures. Each connection point, junction box, and cable gland represents a potential entry path for airborne particulates.

Environmental Exposure During Vehicle Operation

Electric vehicles encounter varied dust exposure throughout their service life. Urban environments generate brake dust particles, tire wear debris, and construction site particulates. Rural and off-road applications expose underbody components to agricultural dust, sand, and soil particles. Coastal regions introduce salt-laden aerosols that accelerate corrosion when combined with particulate infiltration.

Regulatory Compliance Requirements

Automotive standards including ISO 20653 and IEC 60529 establish specific ingress protection criteria for electrical enclosures. Achieving IP6X certification requires demonstrating complete dust-tightness under vacuum conditions with talcum powder at specified concentrations. Verification testing in controlled chamber environments provides documented evidence supporting certification claims and regulatory approvals.

Dust Exposure Scenarios for Electric Vehicle ComponentsBattery Pack Enclosure Validation

Battery management systems monitor individual cell voltages, temperatures, and balancing circuits through complex wiring harnesses. Dust infiltration into battery enclosures can create conductive paths between adjacent terminals, increasing self-discharge rates and creating short-circuit risks. Testing chambers apply calibrated talcum powder (50μm wire diameter standards) to verify that gasket compression, vent filter performance, and weld seam integrity prevent particulate ingress.

Motor Controller and Inverter Testing

Power electronics converting DC battery voltage to three-phase AC motor drive signals generate significant heat requiring active cooling systems. Air intake filters protecting these thermal management pathways require validation under dust loading conditions. Dust proof test chamber testing evaluates filter efficiency degradation, airflow restriction accumulation, and particulate bypass through gasket interfaces.

Charging System Component Evaluation

Onboard chargers, charge port assemblies, and cable connectors experience repeated exposure during vehicle operation and charging events. Testing protocols simulate dust accumulation on electrical contacts, assess insulation resistance degradation, and verify that protective covers maintain sealing effectiveness through multiple operation cycles.

Component Category | Primary Dust Vulnerability | Test Focus Area |

Battery Pack Housing | Gasket interfaces, vent filters | Complete enclosure sealing |

Power Electronics | Cooling air intakes, connector seals | Thermal management integrity |

Charging Systems | Contact surfaces, cable interfaces | Repeated operation durability |

Sensor Assemblies | Optical surfaces, signal connectors | Measurement accuracy retention |

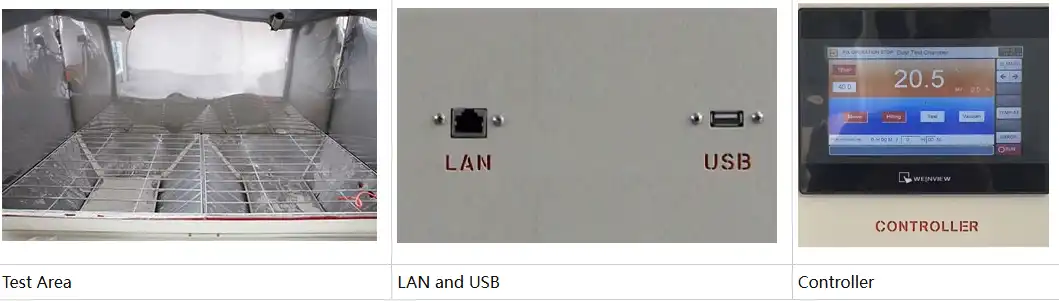

Testing High-Voltage Modules under Dust ConditionsControlled Environment Simulation

Chambers equipped with programmable temperature control (ambient to +50℃) replicate thermal cycling conditions that affect gasket compression and housing expansion. Adjustable vacuum systems create pressure differentials simulating altitude changes and thermal breathing effects. Dust circulation mechanisms maintain uniform particulate distribution throughout the test volume, ensuring consistent exposure across all component surfaces.

|

|

| Name | dust proof test chamber |

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3 mm |

Internal Diameter of IPX6 Nozzle | 12.5 mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

Standardized Test Protocols

Validation procedures specify exposure duration, particle concentration, and environmental conditions matching anticipated service environments. Typical protocols include 8-hour exposure cycles at 2kg/m³ concentration, followed by disassembly inspections documenting particulate accumulation locations. Electrical performance verification measures insulation resistance, dielectric strength, and contact resistance changes attributable to dust exposure.

Performance Metric Documentation

Testing generates quantitative data supporting design validation decisions. Insulation resistance measurements exceeding 100MΩ confirm adequate sealing performance. Contact resistance stability within specified tolerances validates connector sealing effectiveness. Thermal imaging identifies localized heating caused by particulate accumulation on heat transfer surfaces.

Sealing and Insulation Performance EvaluationGasket Compression Analysis

Elastomeric seals maintaining dust-tight enclosures experience compression set degradation under sustained loading and temperature exposure. Dust proof test chamber testing combined with accelerated aging protocols evaluates long-term sealing effectiveness. Post-exposure compression force measurements quantify gasket recovery characteristics and identify potential seal failure modes.

Dust proof test chamber testing combined with accelerated aging protocols evaluates long-term sealing effectiveness. Post-exposure compression force measurements quantify gasket recovery characteristics and identify potential seal failure modes.

Interface Integrity Assessment

Multi-part housings rely on precise manufacturing tolerances maintaining gap dimensions below particulate sizes. Testing reveals whether assembly variations, thermal expansion mismatches, or vibration-induced settling compromises sealing interfaces. Disassembly inspections document dust accumulation patterns indicating preferential infiltration pathways requiring design modifications.

Electrical Isolation Verification

High-voltage systems maintain safety through multiple isolation barriers between energized conductors and chassis ground. Dust accumulation on insulating surfaces can reduce breakdown voltages and create tracking paths under moisture exposure. Testing protocols measure insulation resistance at elevated voltages (typically 2x operating voltage plus 1000V) confirming adequate safety margins post-exposure.

Test Parameter | Acceptance Criteria | Measurement Method |

Insulation Resistance | >100MΩ at 500VDC | Megohmmeter testing |

Contact Resistance | <5mΩ increase | Four-wire measurement |

Enclosure Integrity | Zero particulate ingress | Visual inspection after disassembly |

Accelerated Dust Aging for EV Electrical SystemsCompressed Timeline Validation

Development schedules require validating 10-15 year component lifespans within months. Accelerated testing protocols combine elevated dust concentrations, increased cycle frequencies, and temperature extremes compressing equivalent operational exposures. Chamber programmability enables automated test sequences replicating years of environmental cycling.

Correlation to Field Performance

Establishing acceleration factors requires correlating dust proof test chamber test results with field failure data from operating vehicle fleets. Statistical analysis comparing exposure conditions, failure modes, and component degradation rates validates that chamber testing accurately predicts real-world performance. This correlation enables confident extrapolation from short-duration tests to long-term reliability projections.

Failure Mode Identification

Accelerated testing reveals potential failure mechanisms before mass production deployment. Common dust-related failures include connector fretting corrosion, gasket degradation allowing moisture ingress, and particulate accumulation blocking thermal management pathways. Early identification enables design modifications preventing costly field failures and recall campaigns.

Ensuring Safety and Reliability in EV OperationFire Risk Mitigation

Dust accumulation on high-current terminals can create resistive heating leading to thermal runaway conditions. Validation testing confirms that protective housings prevent dangerous particulate accumulation. Thermal imaging during energized testing identifies potential hot spots requiring design attention.

Electromagnetic Compatibility Protection

Dust infiltration into shielded enclosures compromises electromagnetic interference containment. Testing verifies that sealing maintains RF shielding effectiveness preventing interference with communication systems, sensor networks, and adjacent electronic modules. Conducted and radiated emissions testing post-dust exposure quantifies shielding degradation.

Long-term Warranty Support

Comprehensive dust resistance validation reduces warranty exposure by identifying potential failure modes before customer delivery. Documented test results support warranty claims analysis, distinguishing manufacturing defects from environmental damage. This documentation protects manufacturers from unwarranted liability while ensuring legitimate failures receive appropriate coverage.

Reliability Aspect | Dust Chamber Validation Benefit | Impact on Vehicle Safety |

Thermal Management | Confirms cooling path integrity | Prevents component overheating |

Electrical Isolation | Validates insulation performance | Eliminates shock hazards |

Connector Durability | Verifies contact protection | Maintains signal integrity |

Power EV Durability with LIB Industry's High-Performance Dust Proof Test ChamberAdvanced Testing Capabilities

LIB Industry's dust proof test chambers provide precise environmental control supporting comprehensive validation programs. Programmable color LCD touchscreen controllers enable complex test sequence programming. Ethernet connectivity facilitates remote monitoring and data logging supporting quality management system integration. Internal volumes ranging from 800L to 1000L accommodate complete battery modules, inverter assemblies, and full charging system components.

Compliance-Ready Testing Platform

Equipment designed to IEC 60529 and ISO 20653 standards ensures test results satisfy regulatory requirements. Calibrated dust circulation systems maintain uniform concentrations throughout the exposure period. Integrated vacuum systems with precision pressure regulation replicate standardized test conditions. Documentation packages support certification submissions and audit requirements.

Manufacturing Support Services

Beyond equipment supply, LIB Industry provides comprehensive technical support including test protocol development, operator training, and ongoing calibration services. Applications engineering assistance helps customers optimize test procedures for specific component geometries and validation requirements. This turn-key solution approach accelerates time-to-market while ensuring robust validation data quality.

Conclusion

Dust resistance validation represents a critical quality gate ensuring electric vehicle electrical systems withstand real-world environmental challenges. Comprehensive testing in controlled chamber environments identifies design vulnerabilities, validates protective measures, and generates documentation supporting regulatory compliance. As EV adoption accelerates globally, manufacturers requiring reliable dust proof test chambers gain competitive advantages through reduced warranty costs, enhanced safety records, and accelerated development cycles.

FAQs

What dust concentration levels do automotive standards require for EV component testing?

ISO 20653 and IEC 60529 specify talcum powder at 2kg/m³ concentration for IP6X certification testing. The standardized test uses particles with 50μm nominal wire diameter and 75μm nominal gap width between wires, creating representative worst-case exposure conditions for electrical enclosures.

How long should dust exposure testing run for reliable EV component validation?

Standard validation protocols typically specify 8-hour continuous exposure followed by component inspection and electrical performance verification. Accelerated aging programs may extend exposure to 99+ hours at elevated temperatures and dust concentrations, simulating years of operational exposure within compressed timeframes.

Can dust proof test chambers accommodate complete battery pack assemblies?

Modern chambers with 1000L internal volumes easily accommodate full battery modules and large inverter housings. The 1000x1000x1000mm internal dimensions provide sufficient clearance for mounting fixtures while maintaining uniform dust distribution across all component surfaces during testing procedures.

Contact LIB Industry for Your Testing Solutions

LIB Industry, a leading environmental test chamber manufacturer and supplier, delivers high-quality dust proof test chambers backed by comprehensive technical support. Our factory produces CE-certified equipment meeting international standards for automotive component validation. Contact our team at ellen@lib-industry.com to discuss your specific testing requirements and receive a detailed quotation.