Dust Proof Test Chamber Applications in PCB and Component Testing

Modern electronics face relentless challenges from airborne particulates that threaten operational integrity. Printed circuit boards (PCBs) and electronic components require rigorous validation against dust infiltration to guarantee performance across diverse environments. A dust proof test chamber replicates severe conditions where fine particles penetrate enclosures, accumulate on sensitive surfaces, and compromise electrical pathways. This specialized equipment enables manufacturers to identify vulnerabilities early, refine protective measures, and deliver products that withstand industrial, automotive, and outdoor applications. Through controlled exposure to standardized dust concentrations, engineers obtain quantifiable data about sealing effectiveness, material resilience, and long-term reliability before market deployment.

Why Dust Testing is Critical for PCB Reliability?Understanding Contamination Risks

Microscopic particles infiltrate electronic assemblies through ventilation openings, seams, and connector interfaces. Once inside, dust accumulates on solder joints, component leads, and PCB traces, creating conductive bridges that trigger short circuits or increase leakage currents. Environmental test chambers simulate these scenarios by circulating calibrated dust concentrations, exposing assemblies to conditions mirroring years of field deployment within controlled timeframes.

accumulates on solder joints, component leads, and PCB traces, creating conductive bridges that trigger short circuits or increase leakage currents. Environmental test chambers simulate these scenarios by circulating calibrated dust concentrations, exposing assemblies to conditions mirroring years of field deployment within controlled timeframes.

Preventing Field Failures

Products deployed without adequate dust testing face premature failure rates that damage brand reputation and inflate warranty costs. Automotive electronics, industrial controls, and telecommunications equipment operate in environments where silica, metal particles, and organic debris constantly threaten system stability. Validation through dust proof test chambers identifies weak points in enclosure design, allowing engineering teams to implement corrective measures before production scales.

Regulatory Compliance Requirements

International standards mandate dust resistance verification for equipment operating in harsh environments. Ingress Protection (IP) ratings specify the level of protection against solid particle intrusion, with IP5X and IP6X designations requiring specialized testing. Test chambers meeting IEC 60529 and ISO 20653 specifications provide the controlled conditions necessary to certify products, ensuring market access across regulated industries and geographic regions.

Key Dust Proof Test Standards for Electronic ComponentsIEC 60529 Testing Protocol

This international standard defines dust test procedures using talcum powder with particles sized 50 micrometers in diameter. Test specimens remain in chambers maintaining 2-4 kg/m³ dust concentration for prescribed durations, typically eight hours with continuous circulation. Evaluation criteria examine whether dust deposits interfere with safe operation or accumulate in quantities that could compromise protection ratings over the product lifecycle.

|

|

| Name | dust proof test chamber |

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3 mm |

Internal Diameter of IPX6 Nozzle | 12.5 mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

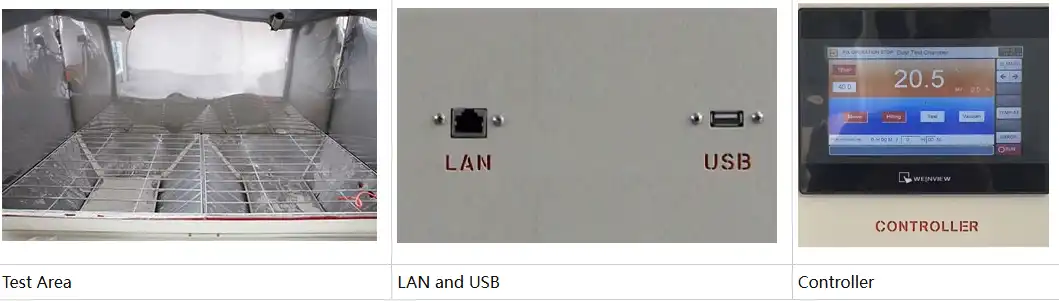

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

ISO 20653 Automotive Applications

Automotive electronics require enhanced testing protocols addressing vehicle-specific contamination scenarios. ISO 20653 extends IEC 60529 requirements with modified dust compositions and environmental conditions reflecting road dust, industrial pollutants, and climatic variations. Dust proof test chambers configured for this standard maintain precise temperature ranges from ambient to 50°C while controlling humidity levels below 30% RH, replicating dashboard installations and under-hood environments.

MIL-STD-810 Military Standards

Defense and aerospace applications demand extreme environmental validation. MIL-STD-810 Method 510 specifies blowing dust and sand tests using Arizona road dust with particle distributions matching desert conditions. Test chambers must generate wind velocities exceeding 18 meters per second while maintaining dust concentrations and exposure durations that stress enclosures beyond commercial requirements, revealing failure modes that only emerge under severe operational stresses.

Standard | Particle Type | Concentration | Test Duration | Application Sector |

IEC 60529 | Talcum powder (50μm) | 2-4 kg/m³ | 8 hours | Consumer electronics, industrial equipment |

ISO 20653 | Road dust mixture | 2-4 kg/m³ | Variable by rating | Automotive electronics, transportation |

MIL-STD-810 | Arizona road dust | High velocity exposure | 6+ hours | Military, aerospace, defense systems |

Simulating Harsh Environments for PCBsTemperature-Controlled Dust Exposure

Real-world electronics encounter simultaneous thermal and particulate stresses. Advanced test chambers integrate nichrome heating elements that elevate internal temperatures to 50°C while maintaining uniform dust circulation. This combination reveals whether thermal expansion compromises sealing integrity or whether elevated temperatures alter particle adhesion characteristics, providing comprehensive validation beyond single-stress testing approaches.

that elevate internal temperatures to 50°C while maintaining uniform dust circulation. This combination reveals whether thermal expansion compromises sealing integrity or whether elevated temperatures alter particle adhesion characteristics, providing comprehensive validation beyond single-stress testing approaches.

Pressure Differential Testing

Ventilated electronics generate internal pressure variations that drive dust infiltration through microscopic gaps. Chambers equipped with vacuum systems and pressure regulation simulate these dynamics by cycling between positive and negative pressure states. The resulting particle penetration patterns identify sealing vulnerabilities that only manifest when equipment operates with active cooling systems or undergoes altitude changes during transportation.

Observation Window Capabilities

Large glass observation ports with integrated dust scrapers enable real-time monitoring throughout test cycles. Engineers document particle accumulation patterns, assess filter loading rates, and identify unexpected entry pathways without interrupting controlled conditions. This visual feedback accelerates design iteration by providing immediate evidence of protective measure effectiveness or revealing failure mechanisms requiring investigation.

Monitoring Component Performance under Dust ExposureElectrical Continuity Verification

Test specimens connect to external monitoring equipment through dust-proof power outlets rated for 16A capacity. Continuous measurement of voltage, current, and resistance parameters throughout exposure cycles detects degradation trends before catastrophic failures occur. Subtle increases in contact resistance or leakage currents signal progressive contamination, enabling engineers to establish maintenance intervals and cleaning protocols for fielded equipment.

Functional Operation Assessment

Active operation during dust testing reveals functional impairments that escape detection during passive exposure. Rotating components, cooling fans, and mechanical switches undergo accelerated wear when contaminated, producing performance degradation data relevant to lifecycle predictions. Dust proof test chambers supporting specimen power delivery enable comprehensive validation where electronics operate normally while dust circulates, replicating actual service conditions.

Post-Test Inspection Protocols

Following exposure cycles, disassembly and microscopic examination quantify particle penetration depth and distribution patterns. Weighing assemblies before and after testing establishes mass gain metrics correlating with dust ingress severity. Combining gravimetric measurements with visual documentation creates objective pass/fail criteria aligned with product specifications, supporting quality assurance decisions backed by reproducible evidence.

Measurement Parameter | Monitoring Method | Acceptance Criteria | Failure Indication |

Electrical resistance | Continuous ohmmeter readings | <5% deviation from baseline | >10% increase suggests contamination |

Functional operation | Active device testing | All features operational | Intermittent faults or degraded performance |

Mass gain | Precision weighing | <0.5g increase per 1000cm² | Excessive accumulation indicating poor sealing |

Material and Design Considerations for Dust ResistanceGasket Selection Strategies

Sealing materials must maintain compression across temperature ranges while resisting abrasive particle erosion. Silicone gaskets offer temperature stability, but closed-cell foam provides superior dust barrier properties for low-pressure applications. Test chamber validation compares competing materials under identical conditions, generating empirical data that informs material selection decisions rather than relying solely on supplier specifications.

Enclosure Geometry Optimization

Labyrinth seals, overlapping joints, and baffle designs create tortuous pathways that reduce particle penetration probability. Computer simulations predict theoretical performance, but dust chamber testing validates actual effectiveness when exposed to turbulent airflow and particle impact forces. Iterative testing of prototype designs identifies optimal configurations balancing manufacturing complexity against protection performance requirements.

Surface Treatment Effects

Conformal coatings, anodizing, and specialized finishes alter particle adhesion characteristics on PCB assemblies and enclosure surfaces. Chamber testing with coated and uncoated specimens quantifies protection improvements, justifying additional processing costs through measurable reliability enhancements. Comparative studies reveal which treatments provide adequate protection versus those delivering marginal benefits insufficient to warrant production implementation.

Predicting Long-term PCB StabilityAccelerated Lifecycle Testing

Condensing years of environmental exposure into concentrated test cycles requires elevated stress levels that accelerate degradation mechanisms without introducing unrealistic failure modes. Chambers maintaining 2-4 kg/m³ concentrations far exceed typical ambient conditions, compressing timeline predictions when correlated with field data. Statistical models translate chamber hours into equivalent operational years, supporting warranty calculations and maintenance scheduling.

Correlation with Field Data

Validation programs compare dust proof test chamber predictions against actual product performance in deployed environments. Telemetry from fielded electronics provides contamination accumulation rates, failure distributions, and maintenance intervention requirements. Aligning test protocols with real-world outcomes refines acceleration factors and ensures chamber testing accurately represents service life expectations across varied deployment scenarios.

Establishing Maintenance Intervals

Dust testing data informs service documentation specifying cleaning frequencies and filter replacement schedules. Quantifying performance degradation rates versus particle exposure enables condition-based maintenance strategies that optimize operational costs while preventing premature failures. Chamber testing establishes thresholds where intervention becomes necessary, replacing arbitrary time-based maintenance with evidence-driven schedules.

Test Duration | Equivalent Field Exposure | Typical Assessment | Application Example |

8 hours | 1-2 years moderate environment | Standard IP rating verification | Indoor industrial controls |

24 hours | 3-5 years harsh environment | Extended reliability validation | Outdoor telecommunications |

72 hours | 10+ years extreme conditions | Military/aerospace qualification | Defense systems, aviation |

Ensure Electronics Reliability with LIB Industry's Advanced Dust Proof Test ChamberProgrammable Control Capabilities

Modern test chambers feature color LCD touchscreen controllers with Ethernet connectivity, enabling remote monitoring and automated test sequence execution. Programmable parameters include temperature ramping profiles, dust circulation intervals, and pressure cycling patterns that replicate specific deployment scenarios. PC connectivity facilitates data logging and report generation, streamlining compliance documentation and design validation workflows.

Precision Environmental Control

Maintaining stable test conditions requires sophisticated climate management systems. Chambers regulate temperature within ±2°C across the working volume while humidity control prevents condensation that would alter particle characteristics. Pressure gauges, air filters, and regulators ensure reproducible conditions between test runs, eliminating variability that could compromise comparative studies or regulatory submissions.

Robust Construction Standards

Test equipment endures continuous operation with abrasive materials circulating at high velocities. Chambers constructed from 304 stainless steel interior surfaces resist corrosion and particle embedding, while cold-rolled steel exteriors with electrostatic powder coating withstand industrial environments. Electromagnetic door locks prevent accidental opening during test cycles, protecting personnel and maintaining chamber integrity throughout demanding validation programs.

Versatile Configuration Options

Multiple chamber sizes accommodate components ranging from individual PCBs to complete electronic enclosures. Models offering 800-liter and 1000-liter internal volumes provide flexibility for testing small assemblies or full-scale products. Caster-mounted designs with foot brakes enable laboratory reconfiguration without permanent installation, adapting test facilities to evolving project requirements and production schedules.

Conclusion

Dust proof test chambers deliver indispensable validation for electronics facing particulate contamination challenges. Through standardized protocols aligned with international requirements, these specialized tools quantify protective measure effectiveness, predict long-term reliability, and prevent costly field failures. Comprehensive testing programs combining environmental stress, electrical monitoring, and material evaluation ensure products meet performance expectations across demanding applications where dust exposure threatens operational integrity and customer satisfaction.

FAQsWhat dust particle size is used in standard PCB testing?

Standard protocols utilize talcum powder with 50-micrometer diameter particles and 75-micrometer wire gap spacing, as specified by IEC 60529. This particle size represents typical environmental contaminants that penetrate enclosures and accumulate on electronic assemblies, providing realistic validation of protective measures against common industrial and commercial dust exposures.

How long should PCBs remain in dust chambers during testing?

Typical test durations range from eight hours for basic IP rating verification to 72 hours for military and aerospace qualifications. Testing duration depends on target protection level, deployment environment severity, and regulatory requirements. Accelerated testing condenses years of field exposure into concentrated cycles through elevated dust concentrations exceeding ambient conditions.

Can dust testing damage electronic components permanently?

Properly configured test protocols minimize component damage risk while revealing design vulnerabilities. Non-powered testing poses minimal risk, whereas active operation testing may accelerate wear on mechanical components. Post-test cleaning removes accumulated particles, allowing engineers to implement design improvements before production. Testing identifies weaknesses requiring correction rather than causing irreparable damage to validated assemblies.

Partner with LIB Industry for Comprehensive Testing Solutions

LIB Industry manufactures advanced dust proof test chambers engineered to international standards, providing manufacturers and suppliers with reliable qualification equipment. Our turn-key solutions encompass research, design, production, commissioning, and training tailored to your specific testing requirements. Contact our technical team at ellen@lib-industry.com to discuss how our dust testing capabilities support your electronics reliability objectives and accelerate product development timelines.