In a highly competitive marketplace, product reliability has become a critical factor for success. Even small amounts of dust can interfere with functionality, shorten service life, and lead to unforeseen failures. Dust test chambers create a controlled and repeatable testing environment, allowing manufacturers to accurately evaluate how products perform under dust exposure and ensure consistent quality, safety, and durability in real-world operating conditions.

Our Dust Proof Test Chambers have earned positive recognition from customers worldwide. A lighting manufacturer in the United States, for example, reported that the chamber provided “stable and reliable performance” during testing. This real-user feedback highlights the effectiveness and dependability of our equipment in practical applications. With these chambers, manufacturers can identify potential vulnerabilities, optimize product designs, and confidently deliver dust-resistant products that meet market and regulatory expectations.

Dust test chambers serve as critical equipment for validating product resistance against particulate intrusion, ensuring compliance with international IP rating standards. These specialized testing environments replicate harsh dusty conditions, allowing manufacturers to verify that electronic components, automotive assemblies, and industrial equipment can withstand exposure to fine particles. Through controlled talcum powder circulation and precise vacuum systems, these chambers simulate real-world scenarios where dust penetration could compromise product functionality, safety, or longevity. Achieving accurate IP5X and IP6X certifications requires sophisticated testing apparatus that maintains consistent particle distribution, regulated temperature conditions, and repeatable test protocols aligned with IEC 60529 and ISO 20653 standards.

What Is Ingress Protection and Why Dust Testing Matters?

Understanding the IP Rating System

The Ingress Protection rating system provides a standardized classification method for assessing how effectively enclosures protect against solid objects and liquids. The two-digit code reveals specific protection levels, with the first digit indicating defense against solid particles ranging from large objects to microscopic dust. Ratings extend from 0 (no protection) to 6 (complete dust-tight protection), offering manufacturers and consumers clear expectations about product durability in challenging environments.

Critical Applications Requiring Dust Resistance

Automotive electronics, outdoor lighting fixtures, industrial sensors, and military equipment all face constant exposure to airborne particulates. A single grain of talcum powder penetrating sensitive circuitry can trigger catastrophic failures, costly warranty claims, and potential safety hazards. Industries operating in desert climates, construction sites, or manufacturing facilities demand products engineered to withstand continuous dust bombardment without performance degradation.

Economic Impact of Insufficient Dust Protection

Product recalls stemming from inadequate dust protection cost manufacturers millions annually in replacement expenses, brand reputation damage, and regulatory penalties. Conducting thorough ingress protection testing during development phases identifies design vulnerabilities early, allowing engineers to implement corrective measures before mass production. This proactive approach reduces field failure rates, extends product lifespan, and strengthens customer confidence in brand reliability.

Overview of IP5X and IP6X Dust Test Requirements

IP5X Dust-Protected Classification

Products achieving IP5X certification demonstrate that dust ingress does not occur in sufficient quantities to interfere with satisfactory operation. While limited dust entry may occur, the amount remains insufficient to compromise equipment functionality or safety. This rating suits applications where complete dust exclusion proves unnecessary but operational reliability under dusty conditions remains essential for product performance.

IP6X Dust-Tight Specification

The IP6X classification represents the highest level of particulate protection, guaranteeing zero dust penetration under specified test conditions. Equipment earning this designation undergoes rigorous evaluation in chambers where talcum powder circulates continuously for eight hours under negative pressure. This stringent standard applies to sealed electronic enclosures, precision instruments, and critical safety equipment where even microscopic particle intrusion could trigger unacceptable consequences.

Regulatory Framework and Compliance Standards

International Electrotechnical Commission standard IEC 60529 establishes the primary testing protocols recognized globally, while ISO 20653 provides supplementary guidance for automotive applications. Military specifications like MIL-STD-810 impose additional requirements for defense-related equipment. Manufacturers targeting multiple markets must ensure their testing procedures satisfy all relevant jurisdictional requirements to achieve comprehensive market access.

IP Rating | Protection Level | Test Duration | Typical Applications |

IP5X | Dust protected | 8 hours | Outdoor lighting, industrial controls |

IP6X | Dust tight | 8 hours | Automotive ECUs, marine electronics |

IP5KX | Enhanced dust protected | Extended cycles | Heavy machinery components |

Test Dust Types and Particle Size Specifications

Talcum Powder as Standard Test Medium

IEC 60529 specifies talcum powder as the primary test medium due to its consistent particle size distribution, chemical stability, and ability to penetrate small openings. The powder's fine texture mimics real-world dust while maintaining reproducible test conditions across different laboratories and testing sessions. Quality control measures ensure each batch meets strict purity standards, preventing contamination that could skew results or damage test specimens.

Particle Size Distribution Requirements

Standard testing protocols mandate particles passing through a 75-micron mesh sieve while being retained by a 50-micron mesh. This narrow size range ensures particles possess sufficient fineness to penetrate potential ingress points without being so coarse that they fail to represent actual environmental threats. Mesh screens integrated into dust test chambers filter oversized particles automatically, maintaining consistent particle size throughout extended testing cycles.

Alternative Test Media for Specialized Applications

Certain industries require testing with specific particulates matching their operational environments. Mining equipment may undergo evaluation with actual mineral dust, while automotive components face testing with road dust mixtures containing silica and organic materials. These customized protocols supplement standard talcum powder testing, providing application-specific validation that generic testing cannot address adequately.

Test Medium | Particle Size Range | Primary Application | Standard Reference |

Talcum powder | 50-75 microns | General electronics | IEC 60529 |

Arizona road dust | Variable composition | Automotive testing | ISO 20653 |

Silica dust | 1-10 microns | Industrial equipment | MIL-STD-810 |

How Dust Test Chambers Simulate Real-World Ingress Conditions?

Circulation System Design and Function

Advanced dust proof chambers employ sophisticated circulation mechanisms that suspend talcum powder particles uniformly throughout the testing volume. Blower systems create controlled air currents that maintain consistent particle concentration, preventing settling or stratification that would compromise test validity. The funnel-shaped bottom design facilitates powder recovery while preventing accumulation that could clog circulation pathways or create uneven distribution patterns affecting test accuracy.

Vacuum System and Negative Pressure Application

Testing protocols require creating negative pressure within the specimen to simulate suction forces that might draw dust into enclosures during normal operation. Equipped with precision pressure gauges, air filters, and pressure regulators, the vacuum system applies calibrated negative pressure ranging from 2 to 20 millibars depending on enclosure volume. This pressure differential replicates breathing effects caused by temperature cycling, altitude changes, or fan operation in actual service conditions.

Temperature and Humidity Control Integration

Maintaining proper environmental conditions proves crucial for repeatable results. Heating elements prevent moisture accumulation that causes powder clumping, ensuring particles remain free-flowing throughout testing cycles. Temperature control systems regulate chamber conditions from ambient up to 50°C, accommodating testing requirements for components operating in elevated temperature environments while preventing condensation that would invalidate test results.

Test Procedures for Verifying IP Dust Protection Levels

Pre-Test Specimen Preparation and Inspection

Thorough visual inspection identifies existing defects, manufacturing irregularities, or damage that could compromise test validity. Inspectors document baseline conditions through photographs and detailed written descriptions, establishing reference points for post-test comparison. Specimens undergo cleaning to remove manufacturing residues, followed by precise weight measurements recorded to detect minute dust ingress quantities during subsequent evaluation.

Execution of Standard Test Cycle

The specimen undergoes suspension within the test chamber with any ports or openings positioned according to standard requirements. Chamber operation initiates dust circulation for eight continuous hours while maintaining specified negative pressure through vacuum connections. Programmable controllers manage blowing intervals, fight times, and environmental parameters automatically, eliminating human error that could affect test consistency or compromise result validity.

Post-Test Evaluation and Documentation

Following the eight-hour exposure period, technicians carefully extract specimens and conduct comprehensive inspections to assess dust penetration. For IP5X testing, examiners verify that any dust entry remains insufficient to impair operation, while IP6X evaluation confirms complete absence of particle intrusion. Photographic documentation, weight measurements, and detailed inspection reports provide objective evidence supporting certification claims and regulatory submissions.

Test Phase | Key Parameters | Duration | Critical Checkpoints |

Pre-test preparation | Weight, visual condition | 30-60 minutes | Seal integrity, port condition |

Active testing | Pressure, circulation, temperature | 8 hours | Consistent particle density |

Post-test evaluation | Dust detection, functionality | 60-90 minutes | Interior inspection, operation verification |

Interpreting Test Results for IP Rating Certification

Criteria for IP5X Qualification

Successful IP5X certification requires demonstrating that dust ingress occurs in quantities too limited to affect equipment functionality adversely, typically verified using a dust chamber under controlled conditions. Examiners assess whether accumulated dust interferes with moving parts, blocks ventilation pathways, or deposits on electrical contacts in quantities sufficient to cause operational disruptions. Subjective judgment often applies during evaluation, making experienced assessor involvement essential for consistent certification decisions.

Standards for IP6X Achievement

IP6X designation demands absolute dust exclusion, allowing zero tolerance for particle penetration. Post-test inspection involves complete disassembly revealing interior surfaces examined under magnification for any talcum powder traces. A single visible particle constitutes test failure, requiring design modifications addressing identified ingress pathways. This stringent requirement drives manufacturers toward robust sealing solutions, precision gasket materials, and enclosure designs eliminating potential particle entry points.

Common Failure Modes and Corrective Actions

Seal compression inadequacy, improper gasket material selection, and manufacturing tolerance accumulation represent frequent causes of dust test failures. Cable entry points, mounting screw penetrations, and interface seams present particular vulnerability where design compromises leak integrity. Failure analysis identifies specific ingress pathways, guiding engineering teams toward targeted improvements such as enhanced gasket specifications, modified seal geometries, or additional protective barriers preventing particle infiltration.

Achieve Precise IP Ratings with LIB Industry's Dust Test Chambers

|

|

| Name | dust test chamber |

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3 mm |

Internal Diameter of IPX6 Nozzle | 12.5 mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

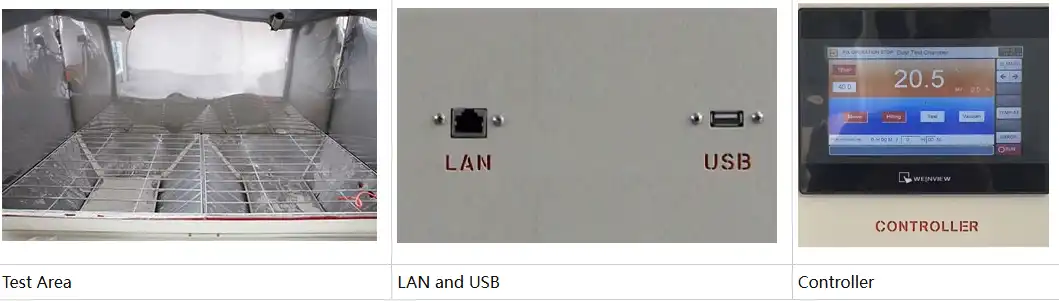

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Build-in Water Tank(mm) | 370*375*950 |

View Window Size(mm) | 475*475 |

Advanced Chamber Design Features

LIB Industry's dust test chambers incorporate funnel-shaped bottoms preventing powder accumulation, heating systems maintaining optimal powder conditions, and precision mesh sieves ensuring consistent particle size distribution. The 304 stainless steel mirror-finish interior resists corrosion while facilitating cleaning between test cycles. Observation windows equipped with wiper mechanisms allow continuous specimen monitoring without compromising chamber integrity or disrupting test conditions.

Comprehensive Testing Capabilities

Available in volumes ranging from 800 to 2000 liters, LIB chambers accommodate diverse specimen sizes from compact electronic modules to large automotive assemblies. Programmable color LCD touchscreen controllers enable precise parameter management, while Ethernet connectivity supports remote monitoring and data logging capabilities. Temperature control extending to 80°C with ±0.5°C accuracy ensures consistent environmental conditions throughout extended testing campaigns.

Quality Assurance and Support Services

Every LIB dust test chamber receives CE certification and undergoes third-party validation by SGS and TUV authorities, guaranteeing compliance with international standards. The company provides comprehensive three-year warranties backed by lifetime service support, with 24/7 global assistance available for technical inquiries or operational challenges. Custom engineering solutions address unique testing requirements that standard configurations cannot accommodate, ensuring optimal results for specialized applications.

Conclusion

Dust test chambers represent indispensable tools for manufacturers pursuing IP rating certification, enabling rigorous validation of product resistance against particulate intrusion. Through controlled environments replicating real-world dusty conditions, these chambers provide objective evidence supporting IP5X and IP6X certification claims. Advanced circulation systems, precise vacuum controls, and programmable automation ensure repeatable results meeting international standards. As product reliability expectations continue rising across industries, investing in quality dust testing equipment becomes essential for maintaining competitive advantage and protecting brand reputation.

FAQs

What differentiates IP5X from IP6X dust protection ratings?

IP5X permits limited dust entry that doesn't affect operation, while IP6X requires complete dust exclusion with zero particle penetration. IP6X testing applies stricter evaluation criteria, demanding absolute seal integrity verified through post-test disassembly and microscopic inspection of internal surfaces.

How long does standard dust ingress testing require for IP certification?

Standard testing protocols mandate eight continuous hours of dust circulation under negative pressure conditions. This duration ensures adequate exposure revealing potential ingress pathways while providing sufficient time for particles to penetrate vulnerable seal areas or enclosure openings.

Can dust test chambers accommodate testing to multiple international standards simultaneously?

Modern chambers support various standards including IEC 60529, ISO 20653, and MIL-STD-810 through programmable controls adjusting parameters like dust concentration, pressure levels, and temperature ranges. This versatility enables manufacturers to validate products against multiple regulatory frameworks using single testing equipment.

Contact LIB Industry Today: As a leading dust test chamber manufacturer and supplier, LIB Industry delivers turnkey environmental testing solutions backed by expert engineering support and comprehensive service. Reach our team at ellen@lib-industry.com to discuss your specific testing requirements and explore custom chamber configurations.